Efficient molding and precise

bending for high quality production

Product Overview

Blow molding machines are specialized equipment designed to produce hollow plastic components by inflating heated plastic into a mold cavity. This process is essential for manufacturing items such as bottles, containers, and other hollow shapes.

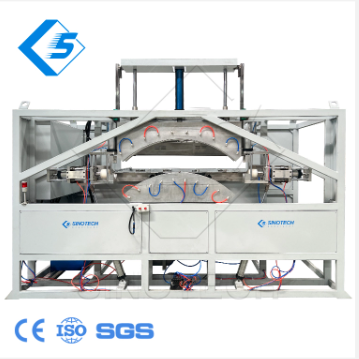

PVC pipe bending machines are designed to reshape straight PVC pipes into desired angles and curves without compromising the integrity of the material. These machines are essential for customizing piping systems in various applications.

Product Categories

Product Advantages

High Productivity

Streamlined processes lead to faster production rates, meeting large-scale manufacturing demands.

Consistent Quality

Precision engineering ensures uniform wall thickness and structural integrity of molded products.

Cost-Effective Operations

Automation reduces labor costs and minimizes material wastage.

Customization Flexibility

Easily adaptable to produce various designs, catering to diverse industry requirements.

Enhanced Efficiency

Streamlines the pipe bending process, reducing time and labor compared to manual methods.

Consistent Results

Delivers uniform bends, minimizing errors and material wastage.

Versatility

Capable of handling various pipe diameters and thicknesses, accommodating a range of project needs.

Safety

Designed with safety features to protect operators during the bending process.

Product Applications

Packaging Industry

Manufacturing of bottles and containers for beverages, cosmetics, and household products.

Automotive Sector

Medical Field

Consumer Goods

Fabrication of toys, sporting goods, and other everyday items.

Reasonable Price

More than 10 precision production line, easy to realize large quantities of goods, to provide you with the best price.

Expertise in type

Expertise in type

Expertise in type

We have an excellent technical team, which can be designed according to customers requirements.

FAQs

Q: What types of materials can be used with blow molding machines?

A: Common materials include polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), and polyethylene terephthalate (PET).

Q: How does the blow molding process ensure product consistency?

A: Advanced control systems monitor parameters like temperature and pressure, ensuring uniform material distribution and consistent product quality.

Q: Can the machine bend pipes of different diameters?

A: Yes, PVC pipe bending machines are designed with adjustable settings to accommodate various pipe sizes.

Q: Is there a risk of pipe deformation during bending?

A: The machine's efficient heating mechanism ensures uniform temperature distribution, minimizing the risk of deformation.

Contact Us

Thank you very much for your interest in us! If you want to contact us, you can contact us through the following methods:

Mob

+8613915728281

sales@sinotechmachine.com

Tel:

+86-512-5849-2269