Full Automatic PVC Pipe Bending Bender Machine

Application

Application

Manual type Semi-auto Plastic PVC Pipe Bending Machine On the basis of internation advanced technology from the developed countries, we produced the PVC pipe bending machine independently. This machine can be used to replace traditional PVC fitting injection machines. And this machine can save cost about 50% than injection machines. We aim to make high quality machines with reasonable price.

This machine can bend the pipes at the same time of making socket.

Function

- Bend PVC pipes.

- Bend and socketing PVC pipe in one end.

- Bend and socketing PVC pipes in both ends

Main advantages:

- PERFECT ROUNDNESS of the entire bend;

- HIGH OUTPUT;

- Length, angle and radius of the bends are variable;

- High level of technology;

- User-friendly machine;

- Reliability, efficiency, low maintenance;

- Compact machine - small size.

| Technical Parameters of PGW75 |

| 1 | Pipe Outer Diameter | OD50-110m |

| 2 | Heating Method | Ceramic infrared heating |

| 3 | Ceramic plate | Elstein, Germany |

| 4 | Quantity of ceramic plate | 15pcs |

| 5 | Power of belling heating oven | 0.5kw*3 |

| 6 | Quantity of belling heating oven | 2 |

| 7 | Power of bending heating oven | 0.65kw*3 |

| 8 | Quantity of bending heating oven | 3 |

| 9 | Hydraulic station | 2 |

| 10 | Chiller of hydraulic oil | 2sets |

| 11 | Oil pump power | 3.75kw |

| 12 | Quantity of oil pump | 2 |

| 13 | Pipe rotate motor | 0.09kw*2 |

| 14 | Up-down motor | 0.75kw*1 |

| 15 | Total heating Power | 17.5kw |

| 16 | Cooling method | Air cooling |

| 17 | Forming type | Bend and socket |

| 18 | socketing station | 3×2 |

| 19 | socket type | U type |

| 20 | hydraulic oil | 46# wear resistance hydraulic oil |

| 21 | Max heating temperature | 450℃ |

| 22 | Air pressure | 0.6-0.8Mpa |

| 23 | Water pressure | 0.2-0.3Mpa |

| 24 | Oil Pressure | 10Mpa |

| 25 | Energy accumulator | 2 sets |

| 26 | Air bag | 4 sets |

| 27 | Working method | Automatic |

| 28 | Dimension | 3050mm*2300mm*2080mm |

| 29 | Weight | 4.8T |

| 30 | Power Voltage | 380V/50HZ |

| 31 | One time bend 1pcs

Capcity about 40-50pcs/hr |

MACHINE PHOTOS AND STRUCTURES:

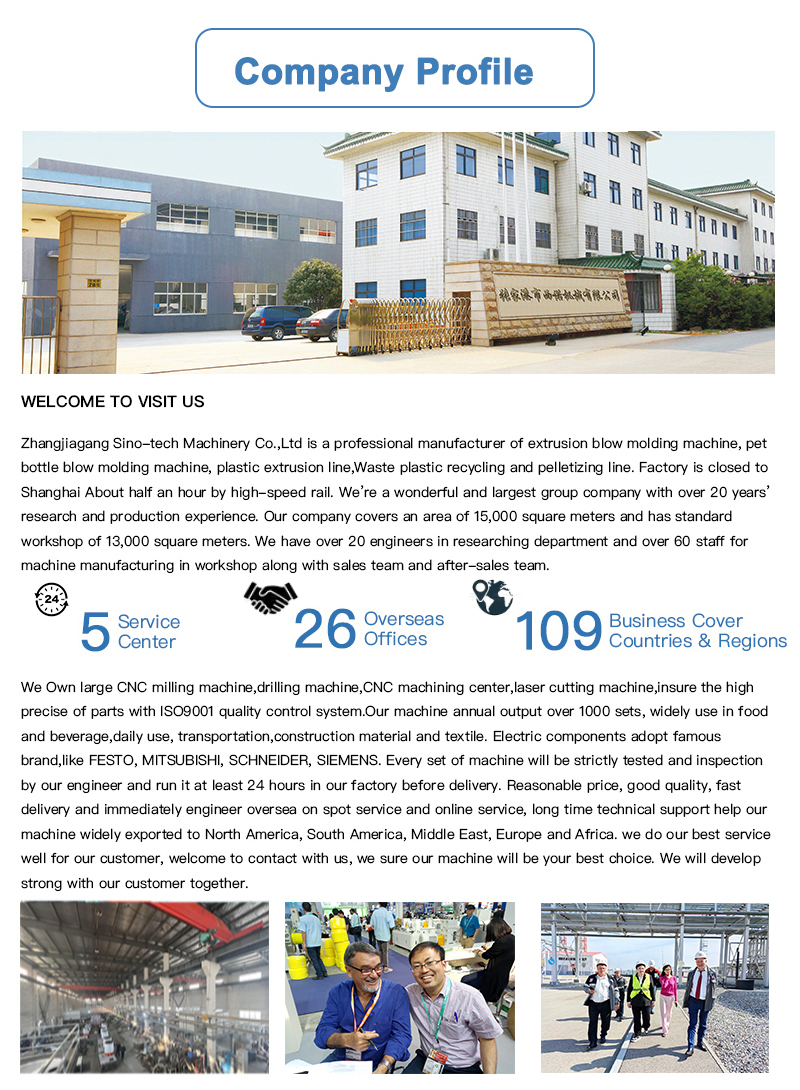

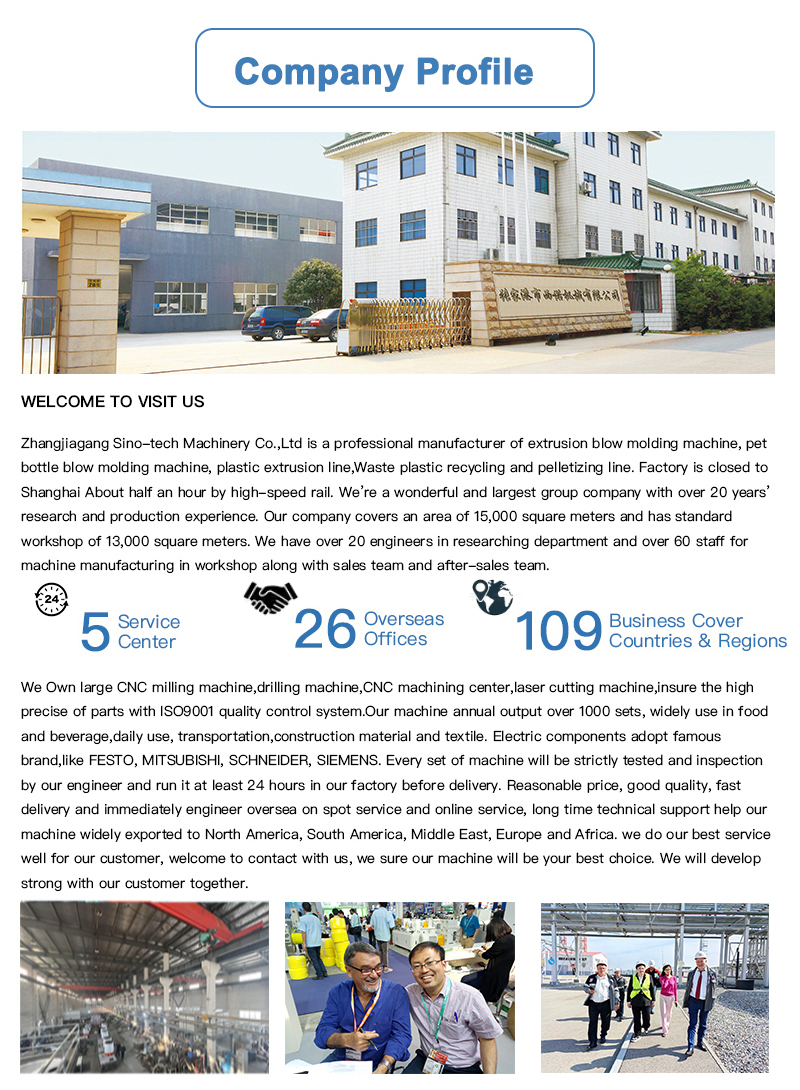

Q: Can we visit your factory?

Sure. We located in Zhangjiagang city which is very near Shanghai. For overseas customers, you can fly to Shanghai Pudong

International Airport. We can pick you up in the Airport. (or Hongqiao International Airport. ) We also provide visit online by

video.

Q: How can we get the exact price of plastic machine?

Contact us with the products size, shape, annual quantity and photo if possible. We can recommend our machine models with

quotation.

Q: Do you provide any spare parts with machine?

Yes, we offer all necessary spare parts before shipment.(contact us for packing list )

Q: How about your after-sale service ?

We offer manual instruction and engineer training before loading,after shipment we provide 24 HRS online support, video technical

support or field installation assist.

Q: What is the lead time?

For customized machine, it takes about 45-60 days after deposit. For stock machine, fast shipment. ( The actual production cycle

will vary according to the degree of customization.)

Q: What is the warranty period for your machine ?

12 months warranty for components and technical support .

Q: Do you provide custom machines?

Most of our machines are customized. Our goal is efficiency and stable performance. We design the machines according to customers

products to meet customer' needs.

Q: How can we install the machine when it arrives?

We can send experienced technicians to customer's country for guiding the installation and commission the machine, also train the

customer's employees.

Q: What's the advantage of SINOTECH?

We provide customers with turnkey projects. Including plant design, plastic machine and mold installation, debugging, also we can

source the auxiliary equipments for customers. We can ship the full set of machines after testing in our factory. It will save a lot of cost and time

Application

Application