SNBL-110 Semi-automatic Hydraulic PVC Pipe Bending Machine

Product Introduction

The SNBL-110 Semi-Automatic Hydraulic PVC Pipe Bending Machine is a highly efficient solution designed to replace traditional PVC fitting injection machines. Developed using advanced international technology, this machine offers an affordable alternative, saving up to 50% of the cost compared to conventional injection methods. It is ideal for businesses seeking cost-effective, high-quality equipment. With its advanced features and user-friendly design, it ensures precision and reliability, making it an excellent choice for high-performance pipe bending operations.

Product Features

Efficient Pipe Bending

This machine is capable of bending PVC pipes with precision, allowing for the simultaneous creation of sockets while bending. This dual functionality improves production efficiency and reduces the need for separate operations.

Precision and Customization

The SNBL-110 allows for variable adjustments in terms of bend length, angle, and radius, offering flexibility in production to meet different project requirements. It ensures perfect roundness of the bends, guaranteeing high-quality results every time.

High Output and Low Maintenance

Designed for high efficiency, this machine delivers a high output rate of 20 pieces per hour for OD 110x3.2mm pipes, while requiring minimal maintenance. The compact design and user-friendly interface ensure ease of use and long-term reliability, making it an ideal choice for continuous production lines.

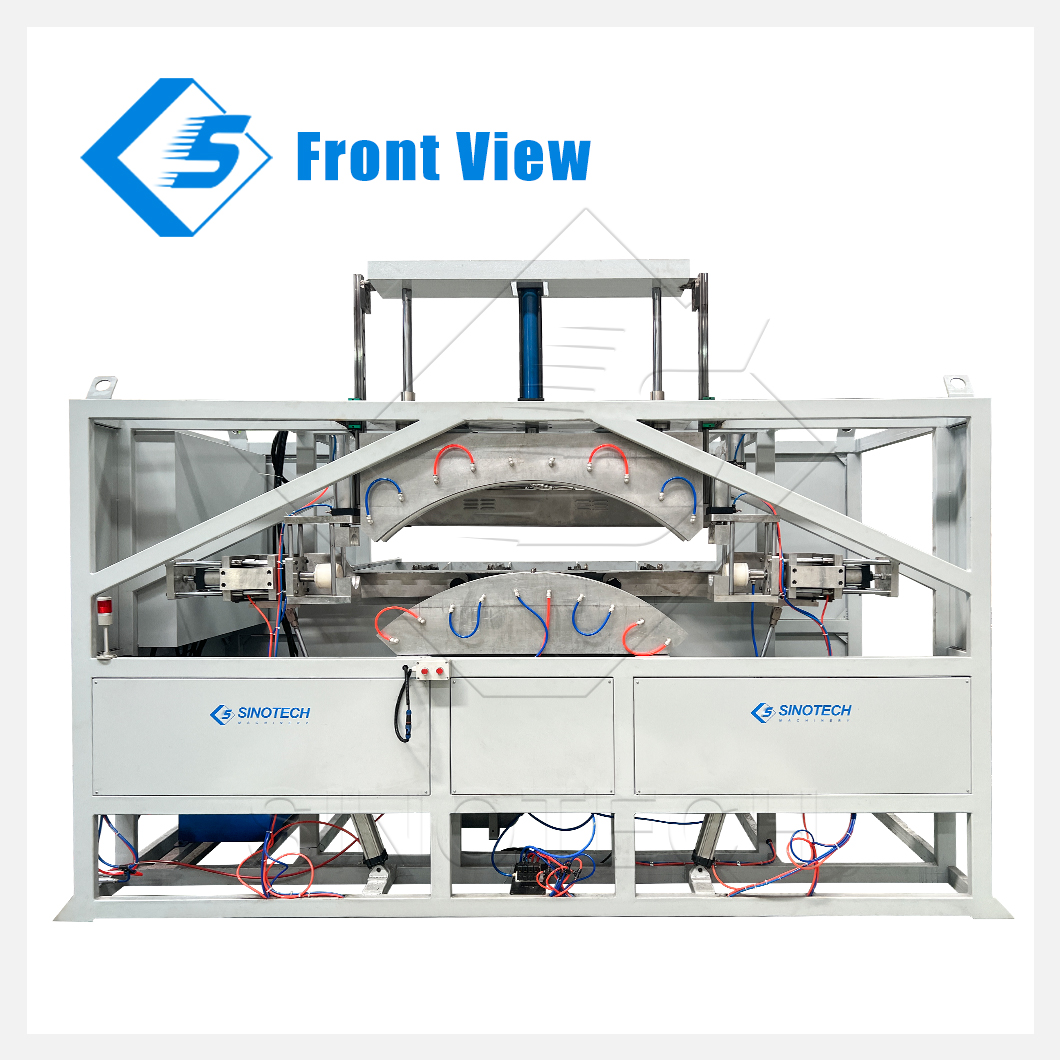

Advanced Technology and Compact Design

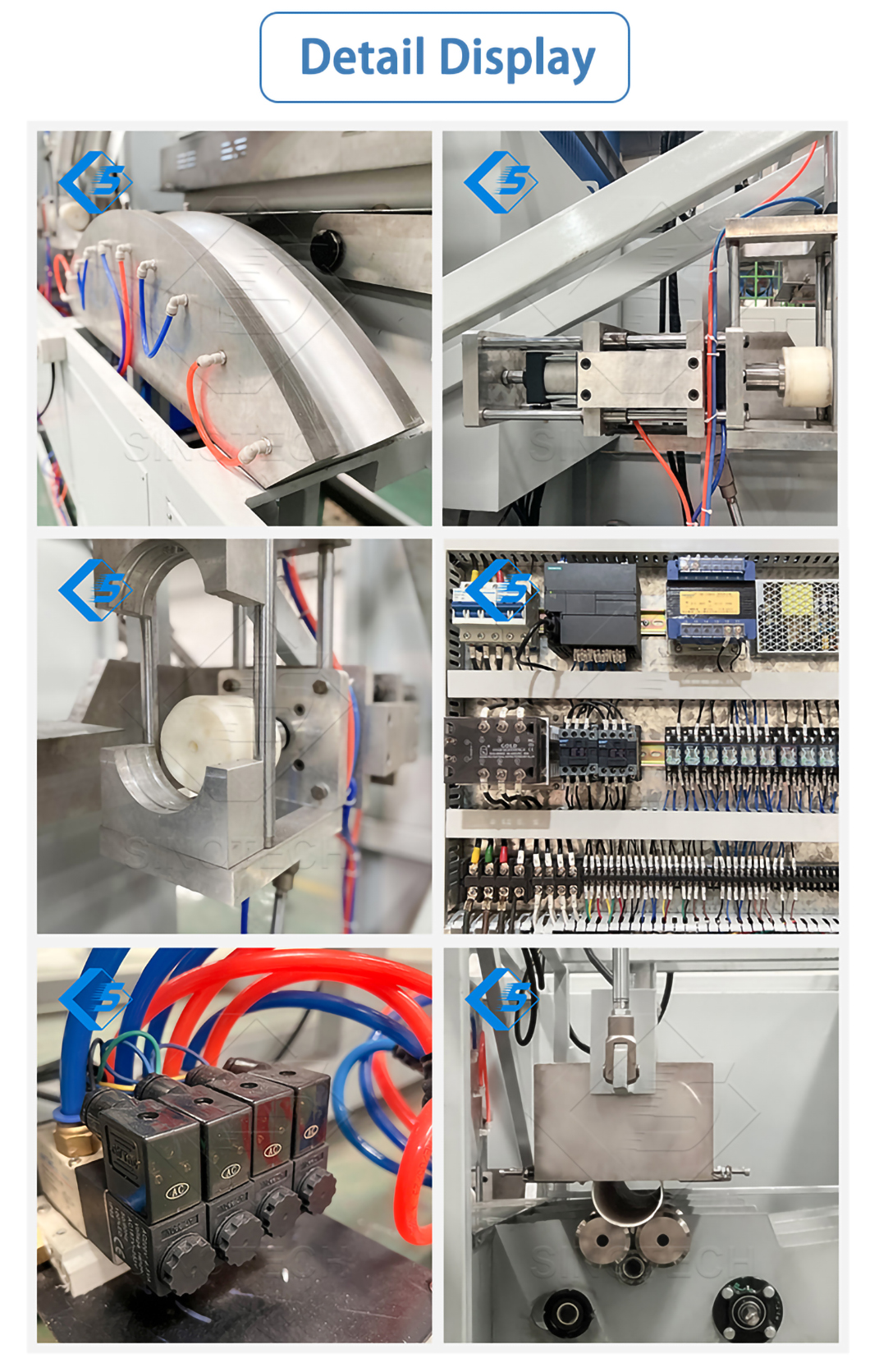

The machine integrates advanced hydraulic and pneumatic systems, ensuring a high level of technology while maintaining a small footprint for space efficiency. The air-cooling system keeps the machine operating at optimal temperatures, while the Airtac components ensure reliability.

Product Advantages

Cost-Effective Solution

Compared to traditional PVC fitting injection machines, the SNBL-110 reduces costs by up to 50% while still offering excellent performance. It provides significant savings in both operational costs and investment, making it a smart choice for businesses looking to optimize their production costs.

Versatility and Customization

This machine supports a wide range of customized bending options, allowing it to handle various pipe sizes and bending angles. The adjustable features make it suitable for different types of projects, offering maximum flexibility for manufacturers.

Durable and Low Maintenance

Built with high-quality components such as Schneider, Omron, and Airtac, the SNBL-110 ensures long-lasting performance and reliability. The hydraulic system is designed for low maintenance, keeping operational downtime to a minimum and ensuring continuous production.

Product Parameters

| Parameter | Value |

| Model | SNBL-110 |

| Standard | U-PVC1002.1-2006 |

| Pipe Diameter | 110 mm |

| Length | Customizable |

| Bending Type | Customized |

| Voltage | 380V, 60Hz, 3-phase |

| Pneumatic Pressure | 0.6-0.8 MPa |

| Hydraulic Pressure | 6.3-8.0 MPa |

| Oil Volume | 80 L (LHM-46) |

| Oil Pump Motor Power | 4.0 kW |

| Machine Speed | 20 pcs/hr for OD 110x3.2 mm pipe |

| Cooling Type | Air-cooling |

| Mold Material | Socket Mold: 45# Steel with Cr Electroplating, Bend Mold: Aluminum |

| Center Height | 1000 mm |

| Machine Color | Light Grey (Customizable) |

| Machine Type | Semi-Automatic |

Product Application

The SNBL-110 Semi-Automatic Hydraulic PVC Pipe Bending Machine is perfect for use in industries where PVC pipes are widely used, such as:

Plumbing and Piping: Ideal for creating bends and sockets for water and sewage pipes, ensuring high-quality fittings for residential, commercial, and industrial applications.

Furniture Manufacturing: Suitable for bending pipes used in the construction of furniture, including desks, chairs, and frames.

Construction Industry: Perfect for creating bends in PVC pipes for various construction applications, ensuring precision and reliable connections.

This machine offers a high-speed and cost-efficient solution for manufacturers looking to streamline their production process and achieve high-quality output.

FAQ

Q: What materials can the SNBL-110 bend?

A: The SNBL-110 is designed for bending PVC pipes, making it ideal for various applications, including plumbing, construction, and furniture manufacturing.

Q: How many pieces per hour can the machine produce?

A: The machine can produce 20 pieces per hour for OD 110x3.2mm pipes, ensuring high output in a short time.

Q: Can this machine handle different pipe sizes?

A: Yes, the SNBL-110 can accommodate various pipe diameters and bending angles, making it highly versatile for different production needs.

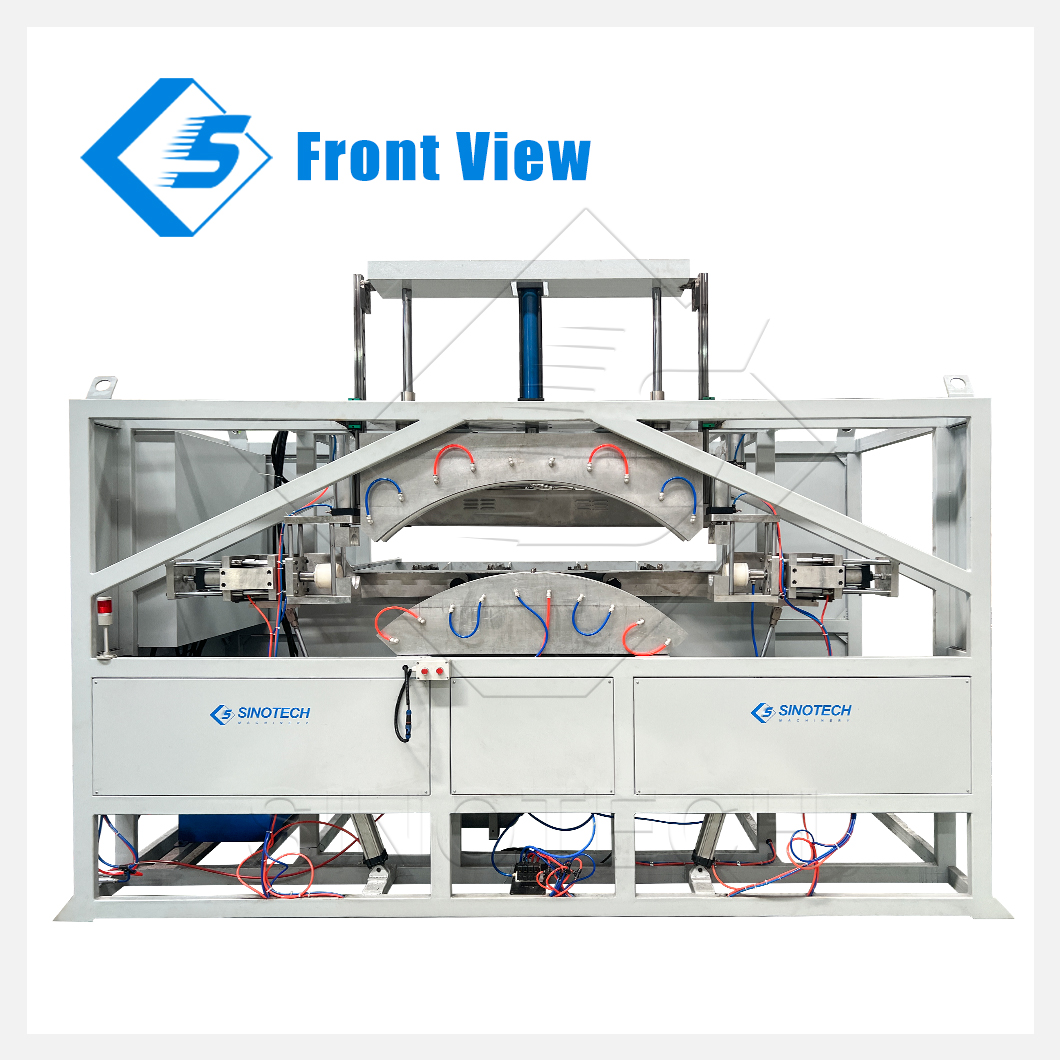

Product Display

Pipe

standards | Model | SNBL-110 |

| Standard | U-PVC1002.1-2006 (as request) |

| Diameter | 110mm |

| Length | According to customer's requirements |

| Bending | Customized |

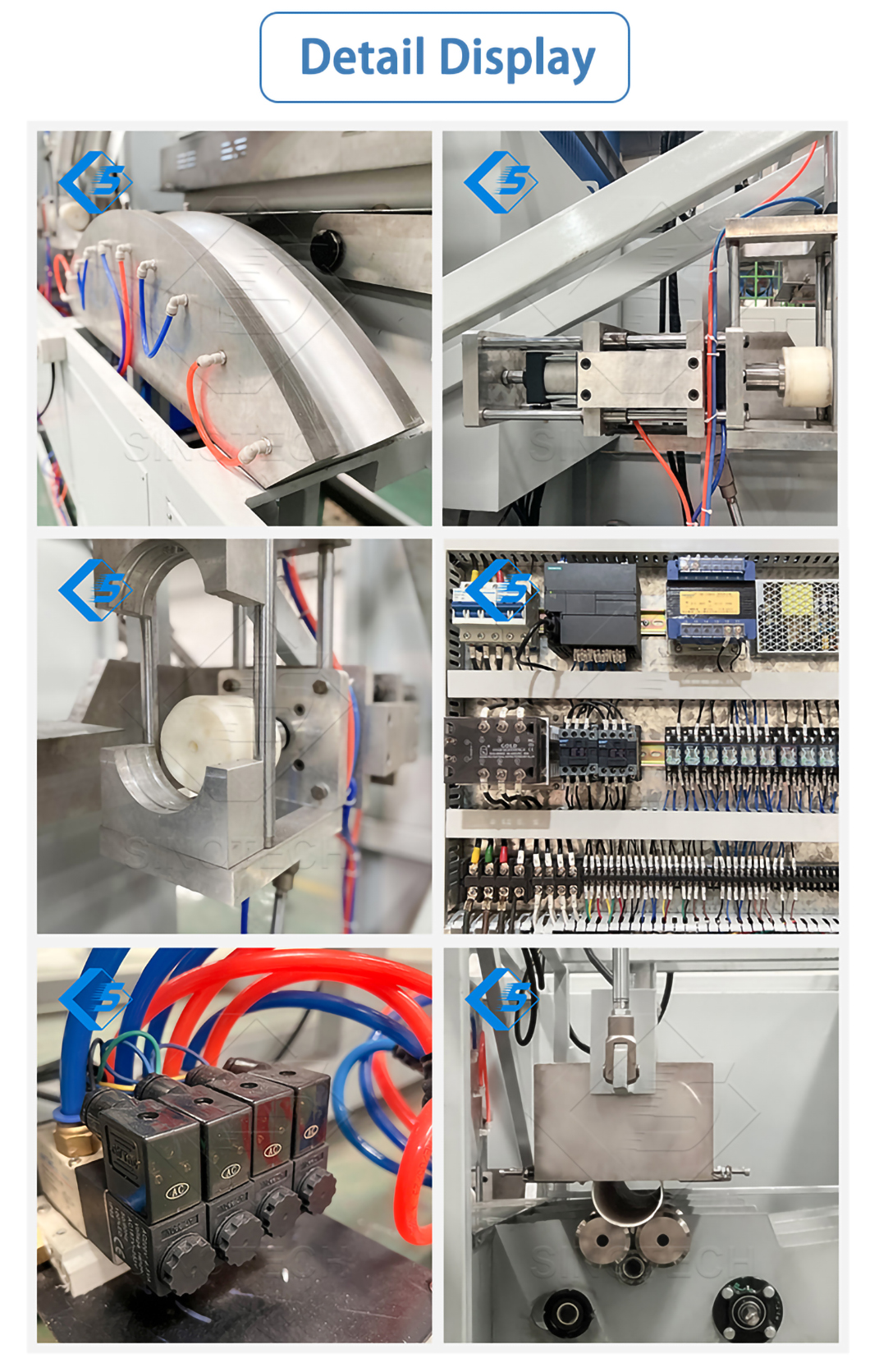

Electrical

component | Iow-voltage apparatus | Schneider, Omron |

| Use voltage | 380V, 60HZ, 3-phase (as request) |

| Pneumatic | Compressed air pressure | 0.6-0.8MPA |

| Pneumatic cylinder | Airtac |

| Pneumatic valve | Airtac (Taiwan brand) |

| Oil-water separator | Airtac |

| Quantity of air bag/collection | 1pcs |

| Hydraulic | Hydraulic pressure | 6.3-8.0MPA |

| Quantity of hydraulic station | 1pcs |

| Hydraulic oil | LHM-46, about 40 litre*2=80L |

| Solenoid valve | OLK Zhejiang |

| Hydraulic valve | Yuken |

| Hydraulic oil pump | Yuken |

| Oil pump motor power | 4.0kw |

| Oil cylinder | SNS |

| Chiller for oil tank | 1pc |

Equipment

appearance | Machine type | Semi-Automatic, one pipes per cycle |

| Center height | 1000mm (as request) |

| Machine color | Light grey (as request) |

| Operating principle | Bend | With air pressure chamber and collapsibel mandrel |

| Cooling type | Air-cooling |

| Machine speed | 20pcs/hr for OD110*3.2mm pipe |

| Mould material | Socket mold: 45# steel with Cr electroplating |

| Bend mold: Aluminum. |

Our Advantages

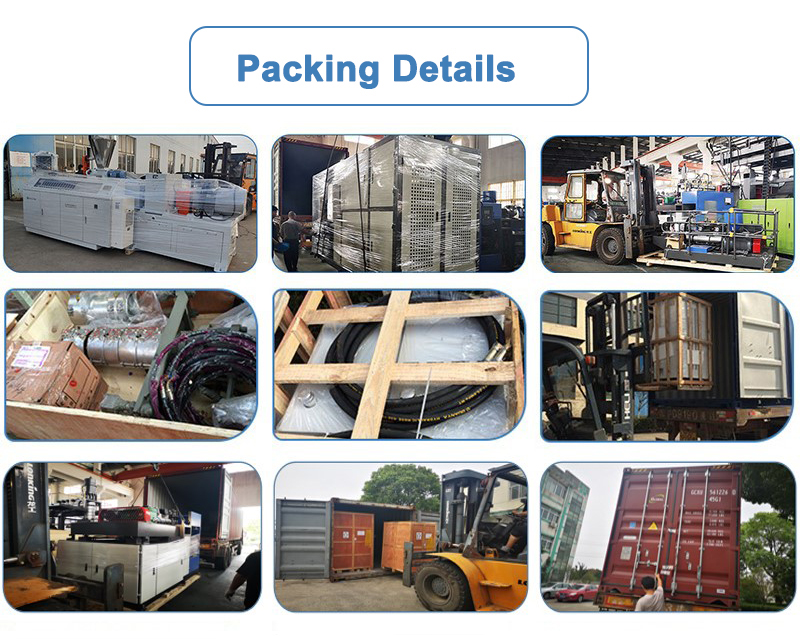

Company Profile

Certificates