1000L Tank Plastic Pallet Big Barrel Container Accumulator Extrusion Blow Molding Moulding Machine for Water Tank or Hydraulic Oil tank

Products Description

STD-1000L Extrusion Blow Molding Machine

Machine Features

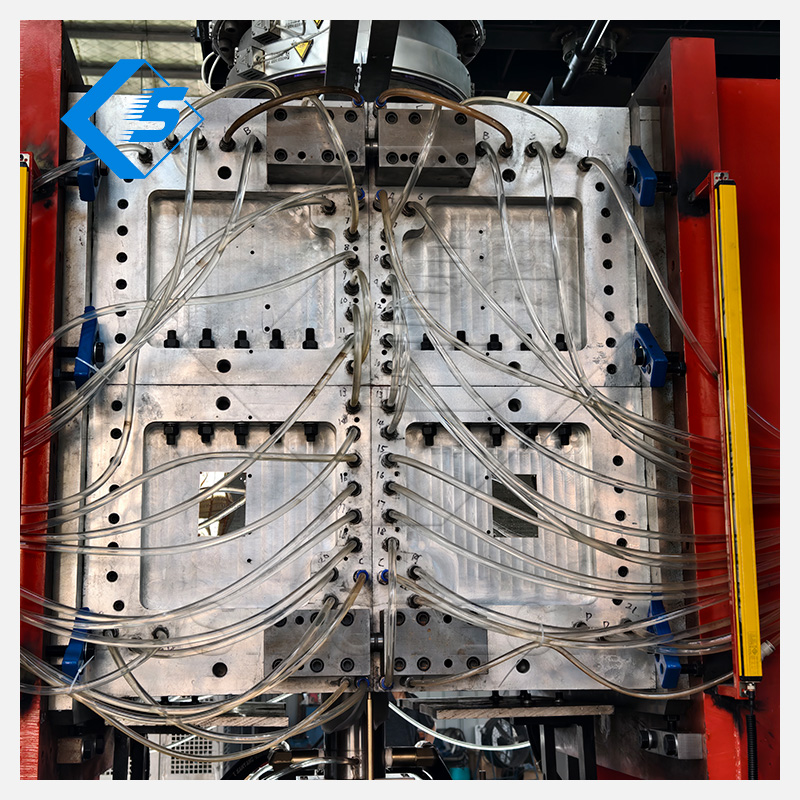

1. Special design for 1000L PE/PP... IBC tanks.

2. Die head design with easy to change the material and color.

3. Latest mold changing system, much faster and easier.

4. Optimized hydraulic system, proportional pressure control

5. Adopts two pull-rod type closing-mold devices by rack and pinion system. The large setting platen is suitable for various sizes of molds

6. Simple structure in linear type, easy in installation and maintenance.

7. Servo system

8. With robot arm take out the finished product

9. One to three multi-layers choose

10. Hydraulic and electric hybrid power design, makes the machine run more speed and more energy-saving.

11. Full Servo system control.

12. Simple structure in linear type, easy in installation and maintenance.

13. With a robot arm take out the finished product.

14. Single die-head and Single station.

Product Introduction

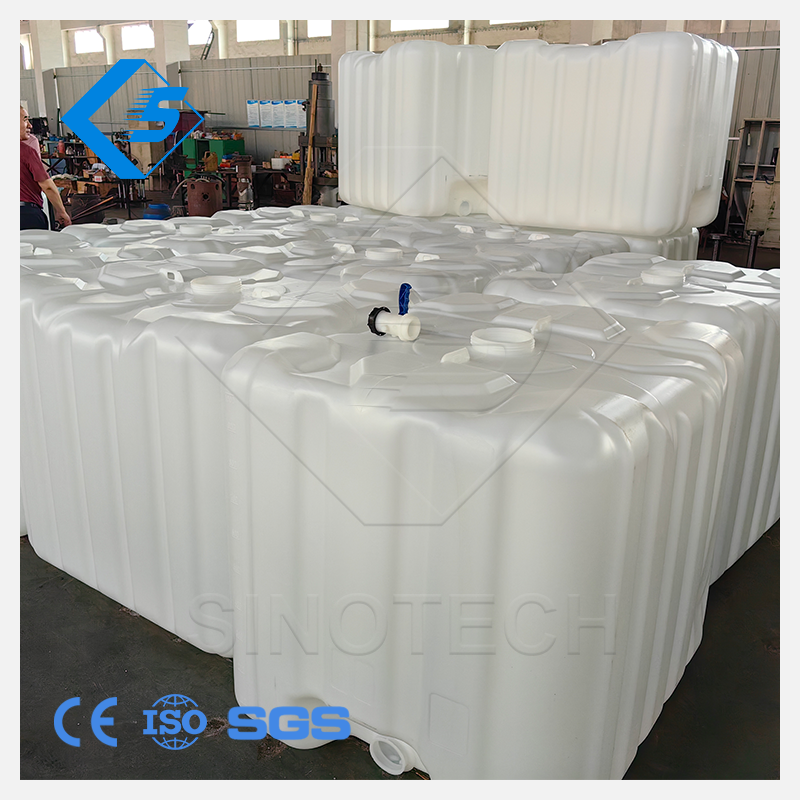

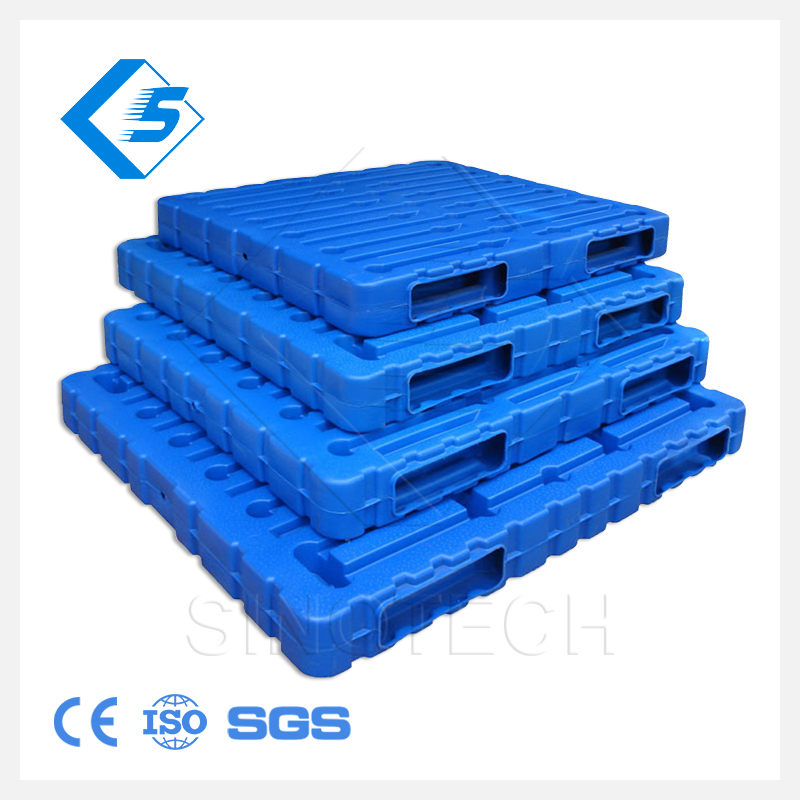

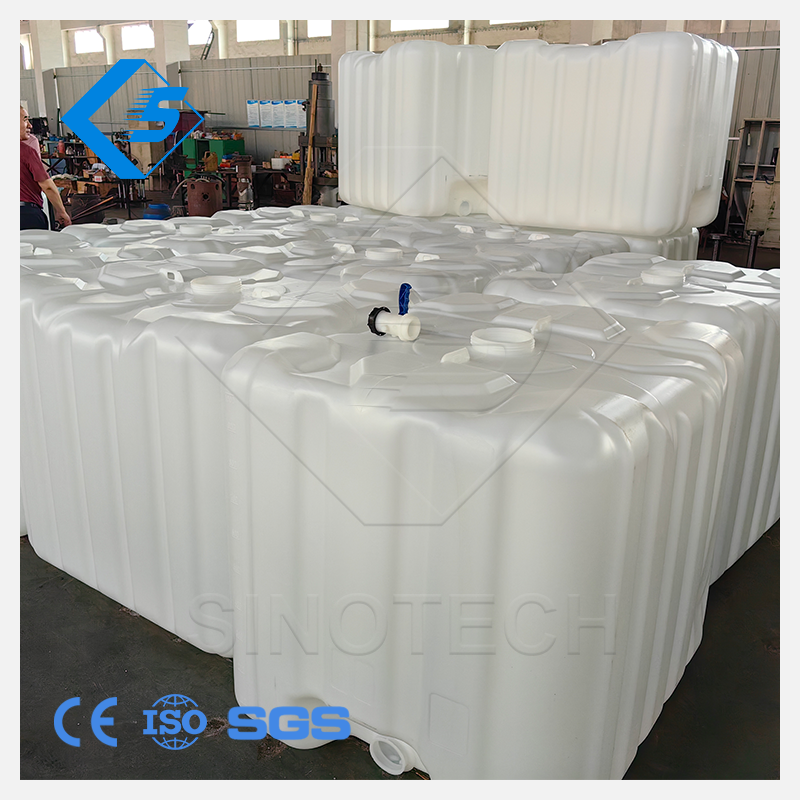

The 1000L Plastic Big Barrel Big Containers Plastic Pallets Blow Molding Machine is engineered for the production of large plastic containers such as 1000L HDPE drums, plastic pallets, and IBC tanks. This versatile machine offers high-speed production capabilities, with the ability to handle 450kg/hr plasticizing capacity. Ideal for industries such as chemical storage, logistics, and industrial packaging, the machine can produce large containers and pallets with precise molding and multi-layer extrusion options. With advanced parison control technology, it ensures uniformity and optimal material distribution.

Designed for heavy-duty use, the STD-1000L series blow molding machine is perfect for manufacturers who require large volumes of plastic containers and industrial pallets with superior strength and durability.

Product Features

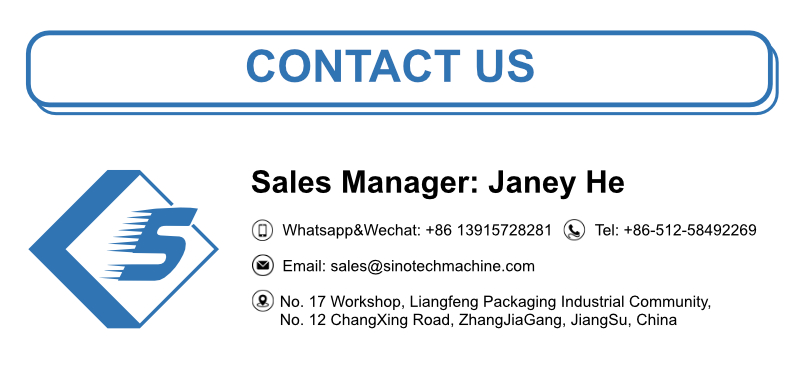

Large-Scale Production: This machine can produce up to 16-18 IBC tanks per hour and 15-17 plastic pallets (1000x1000mm) per hour, making it ideal for high-demand production environments.

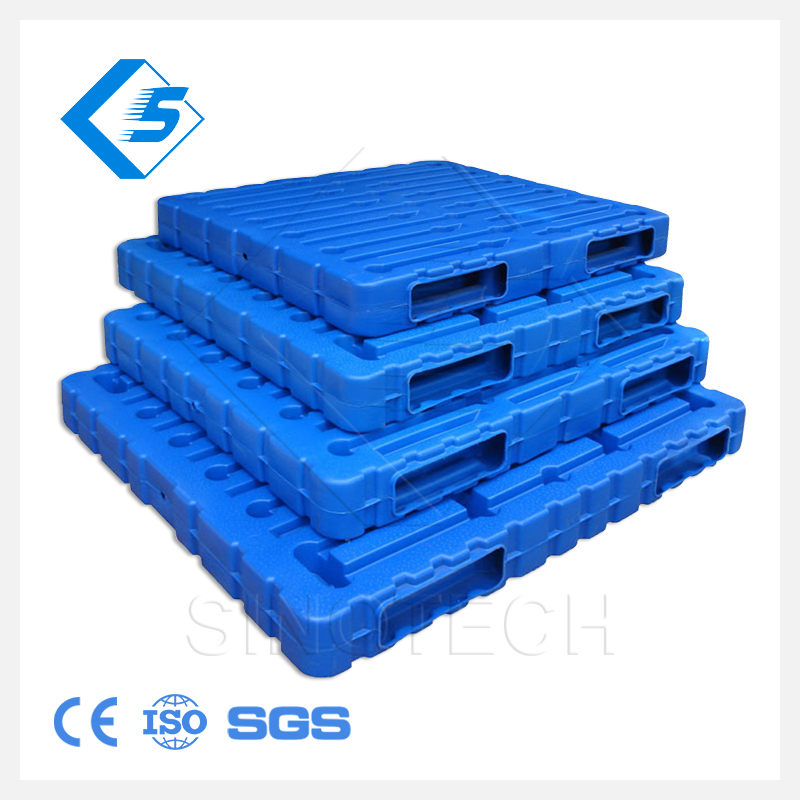

Flexible Die-Head Configurations: The machine comes with a 45L accumulator die head to produce 1000x1000mm pallets. The die head can be swapped to produce smaller drums or other container sizes, offering great flexibility in production.

High Plasticizing Capacity: With a plasticizing capacity of 450kg/hr, this machine can efficiently process HDPE, HMWHDPE, PP, and other materials for large container production.

Product Advantages

Energy-Efficient and Fast: The machine uses servo-drive motors and MOOG parison control systems for optimal energy use while maintaining high-speed production, reducing overall operational costs.

Durability and Precision: Constructed with Aluminum 7075 molds and Beryllium Copper, the machine ensures precise molding and enhanced cooling efficiency, increasing mold life and reducing maintenance.

Product Photos

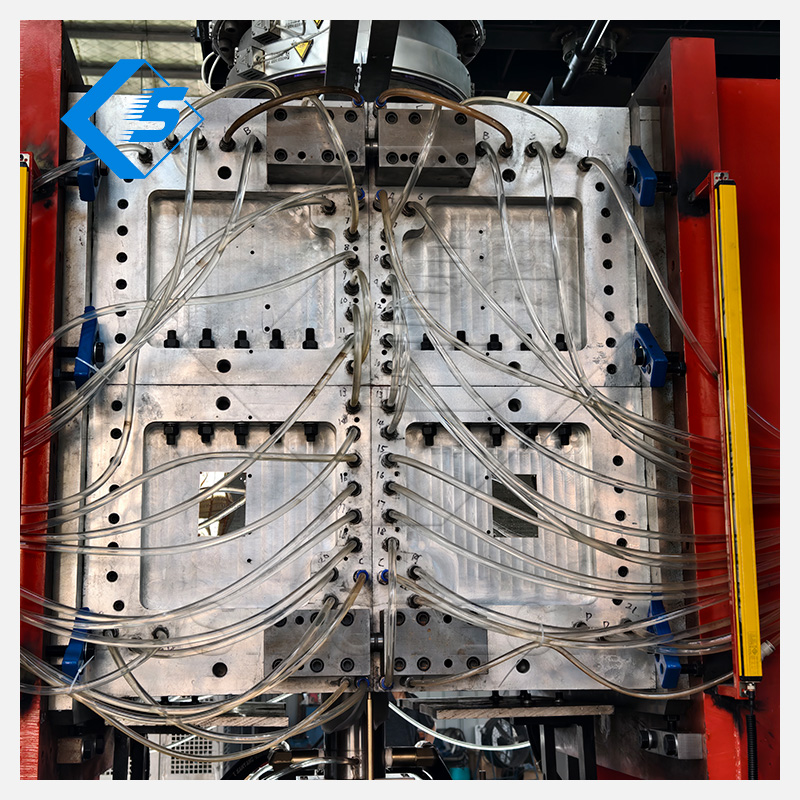

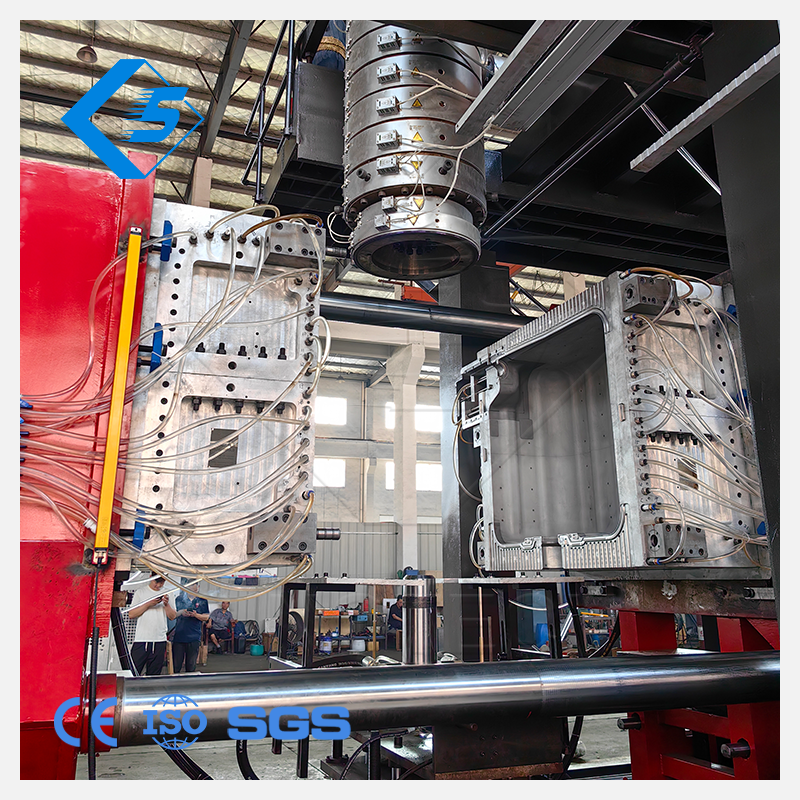

Detailed Images

Product Parameters

Technical Specification | STD-1000L Accumulator |

Extrusion Blow Molding Machine |

|

|

Specifications |

| STD-1000L

|

|

Max. Container Capacity | L | 1000 |

Machine Weight | T | 65 |

Machine Dimension(L*W*H) | M | 9.0*6.5*8.2 |

Average power Consumption | KW | 100 |

Die Head |

Number of Heating Zone | Zone | 8 |

Power of Die Heating | KW | 56 |

Max. Die-pin Diameter | mm | 950 |

Extruder Unit |

Screw Diameter(Single layer) | mm | 120 |

Screw Diameter(Double layers) | mm | 120/120 |

Screw Diameter(Three layers) | mm | 90/120/90 |

Screw L/D ratio | L/D | 30 |

No. of Heating Zone | Zone | 21KW*6*3 |

Heating Power | KW | 88*3 |

Max. Melting Capacity(120mm) | Kg/hr | 450 |

Max. Melting Capacity(90mm) | Kg/hr | 150 |

Screw driving power(Single layer) | KW | 132 |

Screw driving power(Double layers) | KW | 132/132 |

Screw driving power(Three layers) | KW | 75/132/75 |

Clamping Unit |

Max. Mould Size(W*H) | mm | 1500*1500 |

Distance Between Platen | mm | 1200~2600 |

Platen Size(W*H) | mm | 1600*1600 |

Clamping Force | KN | 2000 |

Power |

Total Power | KW | 320 |

Blowing pressure | Mpa | 0.6 |

Air consumption | CBM/hr | 1 |

Average power consumption | KW | 100 |

Final Products

Company Profile

Packaging & Shipping

FAQ

Q: Can we visit your factory?

Sure. We located in Zhangjiagang city which is very near Shanghai. For overseas customers, you can fly to Shanghai Pudong International Airport. We can pick you up in the Airport. (or Hongqiao International Airport. ) We also provide visit online by video.

Q: How can we get the exact price of plastic machine?

Contact us with the products size, shape, annual quantity and photo if possible. We can recommend our machine models with quotation.

Q: Do you provide any spare parts with machine?

Yes, we offer all necessary spare parts before shipment.(contact us for packing list )

Q: How about your after-sale service ?

We offer manual instruction and engineer training before loading,after shipment we provide 24 HRS online support, video technical support or field installation assist.

Q: What is the lead time?

For customized machine, it takes about 45-60 days after deposit. For stock machine, fast shipment. ( The actual production cycle will vary according to the degree of customization.)

Q: What is the warranty period for your machine ?

12 months warranty for components and technical support .

Q: Do you provide custom machines?

Most of our machines are customized. Our goal is efficiency and stable performance. We design the machines according to customers products to meet customer' needs.

Q: How can we install the machine when it arrives?

We can send experienced technicians to customer's country for guiding the installation and commission the machine, also train the customer's employees.

Q: What's the advantage of SINOTECH?

We provide customers with turnkey projects. Including plant design, plastic machine and mold installation, debugging, also we can source the auxiliary equipments for customers. We can ship the full set of machines after testing in our factory. It will save a lot of cost and time.