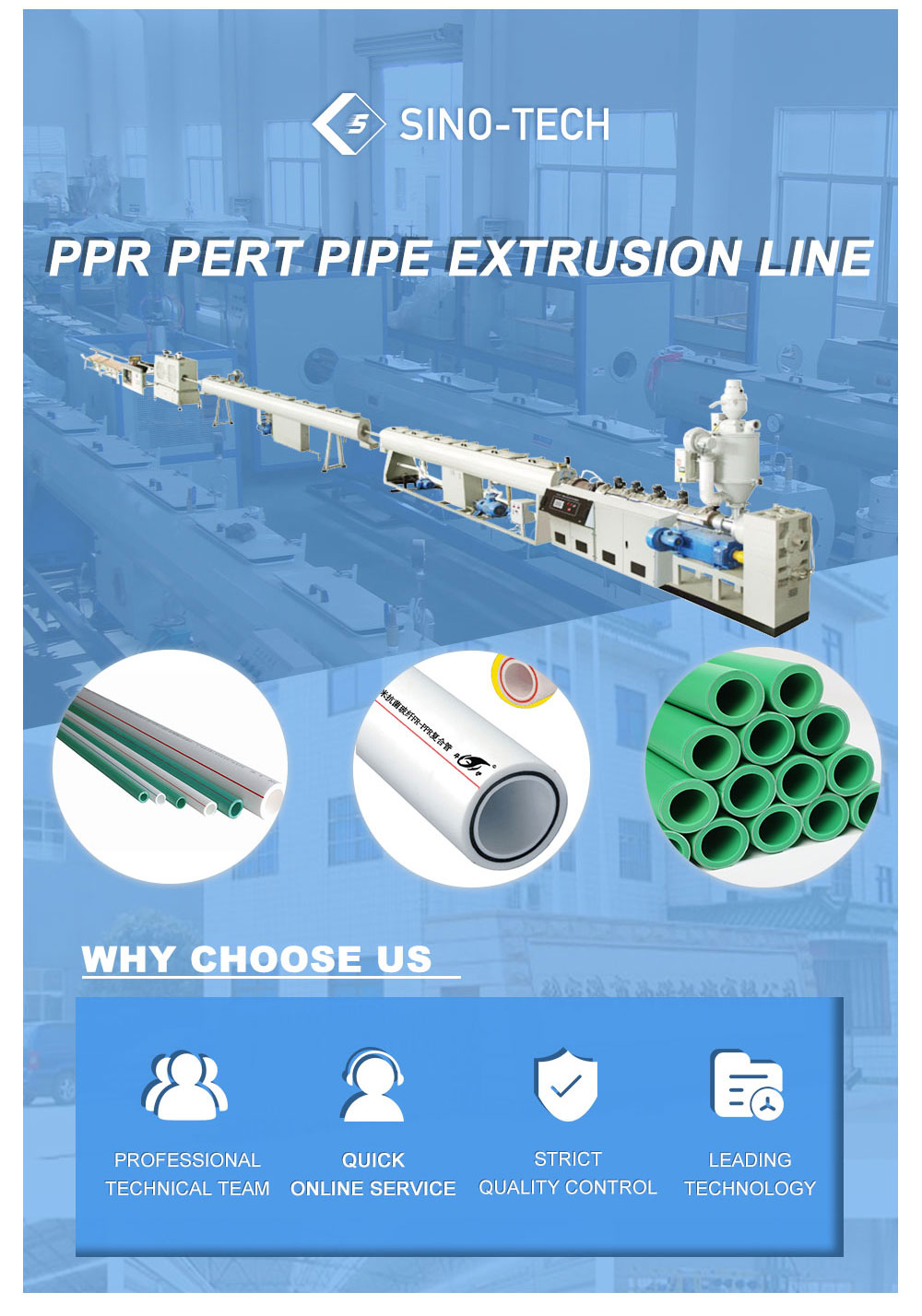

PPR Pipe Extrusion Production Line

Application:

PPR PERT pipe hot water supply or cold drinking water supply with characteristic non toxic,rustless,non-filthily,heater preservation

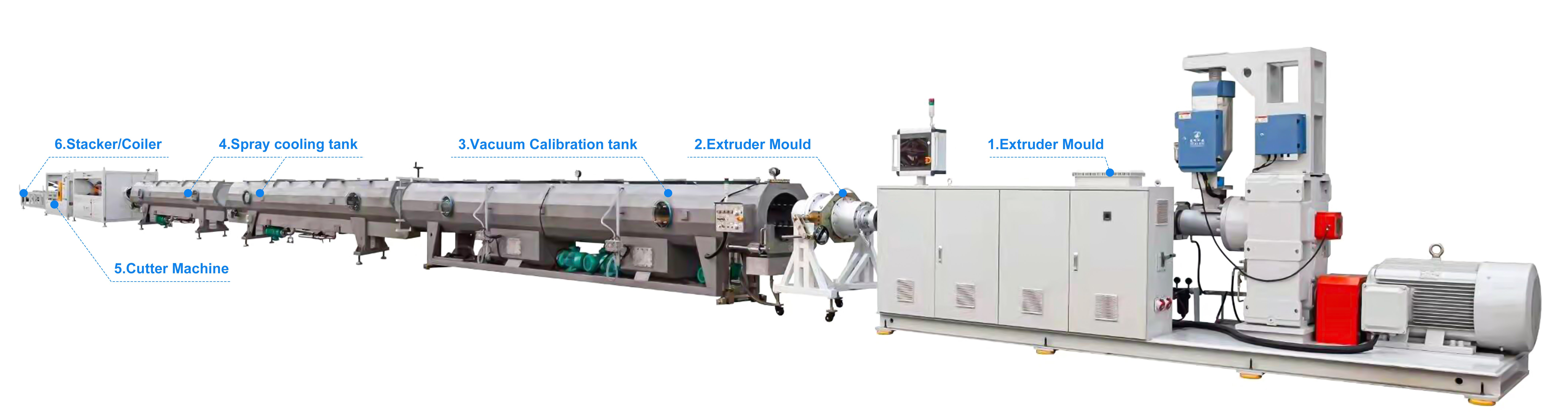

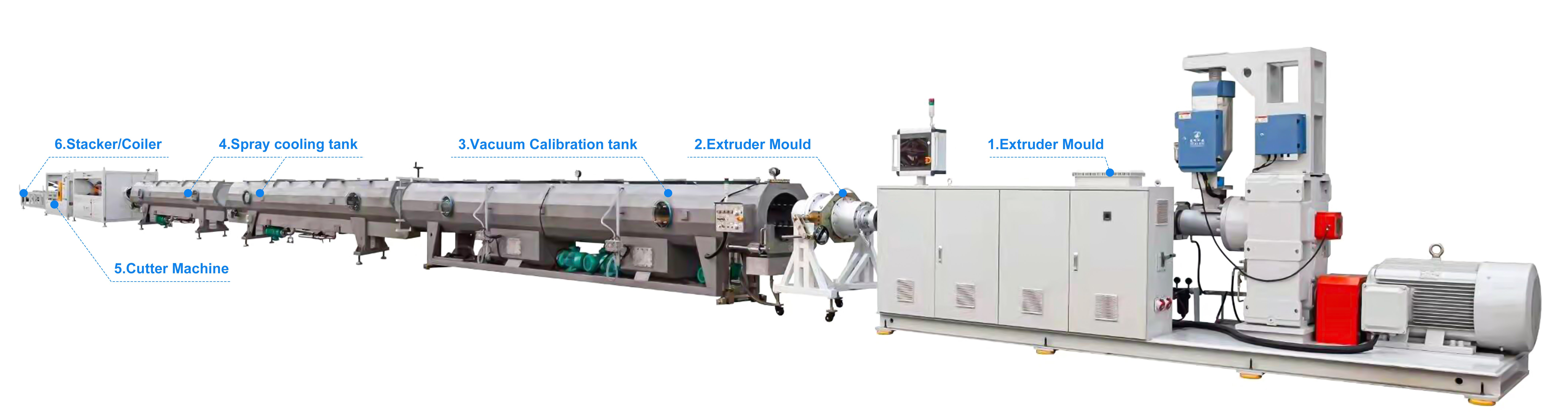

Production Flow:

Material →Color Mixer →Material Feeding →Single Screw Extruder →Extrusion Mould & calibrator → vacuum Calibration Cooling Tank →Spray Cooling Tank →Printer → Haul-off Unit →no dust cutter →stacker

Equipment Features:

PPR Pipe Diameter Range:φ16mm-φ160mm

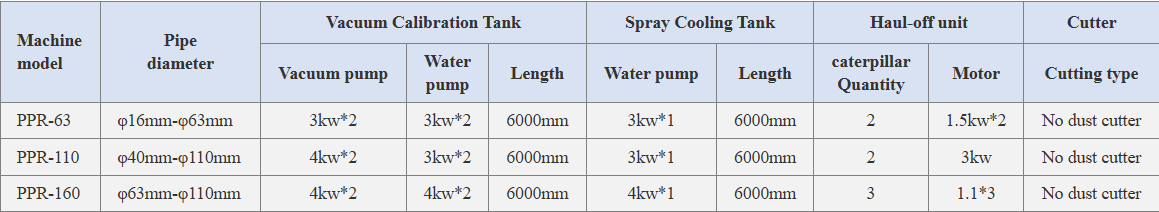

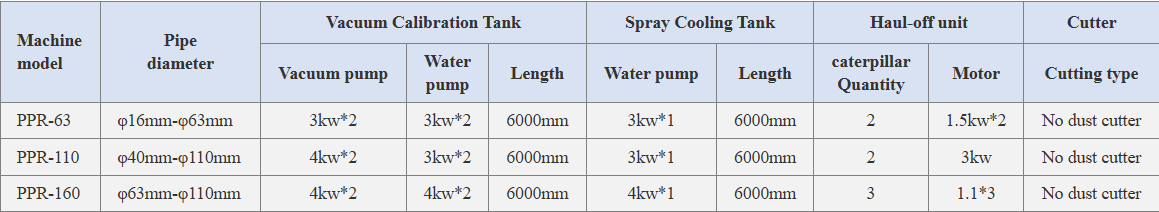

The Vacuum Calibration Tank will be equipped with different quantity and power of water pump and vacuum pump for different pipe diameter

For extruder Temperature Control system,Digital PLC control or Manual Temperature Control Meter

Caterpillar Haul-off unit with two caterpillar, three caterpillar, four caterpillar,six caterpillar,eight caterpillar Twelve Caterpillar design for different range of pipe diameter haul-off

No dust cutter&Planetary cutter can be choosed according to different diameter pipe.

Equip with special mould and other device,it can produce inner wall sprial pipe and Inner wall hollow pipe and three layer pipe.

Easy Operation,Reliable performance,High Extrusion Efficiency, Easy Maintenance

Detailed Photos

Plane Flow

Description of PPR pipe extrusion Line:

Description of PPR pipe extrusion Line:

1.This machine With PLC Control system in the production line, reliable and stable performance.

2.The down stream equipment includes vacuum calibration and cooling unit, haul-off unit, cutting machine and stacker.

3.The calibration unit is equipped with large forced cooling system so that it can provide perfect calibration effect.

4.The hall-off unit is caterpillar style. The lower one is fixed and the upper one can be adjusted according to the plate size.

5.The cutting machine is able to set length and provide accurate automatic cutting.

6.The stacker is attached with material cart and rubber protection layer to prevent products from damage, and easy operation.

Process Flow of PPR pipe extrusion line:

Raw material +color masterbatch+ additive → mixing → Single Screw extruder → PPR pipe extrusion mould → cool molding die → vacuum calibration support → haul-off → cutter → rack → finished product inspecting & packing

Raw materials for pvc ceiling panel:

PPR Granule + color masterbatch + other additives.

Technical information:

| Parts | No. | Name | Brand |

| 1 Screw and barrel | 1 | Design | German design |

| 2 | Main materials | 38CrMoALA |

| 3 | Screw heating | Silicon oil heating |

| 4 | Barrel heater | Cast aluminum heater |

| 5 | Barrel has vacuum exhausting system |

|

| 2 Driving parts | 1 | Main motor | Siemens Brand |

| 2 | Gear box | Top brand in China |

|

| 3 Electric parts | 1 | Inverter | ABB brand |

| 2 | Contactor | Schneider brand |

| 3 | Relay | Schneider brand |

| 4 | Breaker | Delixi brand |

| 5 | Temperature meter | RKC brand |

| 6 | Hauling motor | Densen brand |

| 7 | Hauling gear box | Hard surface gear box |

| 8 | Vacuum pump | Yvhuang brand |

| 9 | Water pump | Yvhuang brand |

| 10 | Cutting motor | Siemens brand |

| 11 | PLC | Schneider brand |

|

| 4 Mechanical parts | We use CNC machines to ensure the precision of our mechanical parts |

|

| 5 Protection system | We have a whole set of protection system for our machines, such as:

1 Current overload protection

2 Torque overload protection

3 Oil path blocking alarm

4 Vacuum overload alarm, and so on. |

| For more technical information please contact us by email. |

model |

PP-R63 |

PP-R110 |

pipe range(mm) |

20-63 |

63-110 |

capacity(kg/h) |

90 |

150 |

center height(mm) |

1000 |

1000 |

single screw

extruder |

extruder model |

SJ65 |

SJ90 |

screw diameter(mm) |

65 |

90 |

L/D |

30:1 32:1 |

28:1 30:132:1 |

Screw rotation speed(rmp) |

80 |

70 |

motor power(kw) |

30/37 |

45/55 |

heating power(kw) |

20 |

30 |

coolin blower power(kw) |

0.18 |

0.18 |

vacuum calibration tank |

length of calibration case(mm) |

6000 |

6000*2 |

vacuum degree(mpa) |

-0.08 |

-0.08 |

absorbing gas speed(m3/h) |

60 |

60*2 |

water pump power(kw) |

2*2.2 |

2*2.2 |

longitudinal moving motor power(kw) |

1.1 |

1.1 |

Spray cooling tank |

length of spraying tank(mm) |

4000-6000 |

6000-8000 |

water pump power(kw) |

2.2 |

2.2 |

haul off |

driving power(kw) |

3 |

5.5 |

max pull(N) |

7000 |

10000 |

effctive haul off length(mm) |

1200 |

1700 |

blade type cutter |

blade diameter(mm) |

350 |

350 |

driving power(kw) |

2.2 |

2.2 |

working air pressure(mpa) |

0.7-0.7 |

0.7-0.7 |

stacker |

length(mm) |

6000 |

600 |

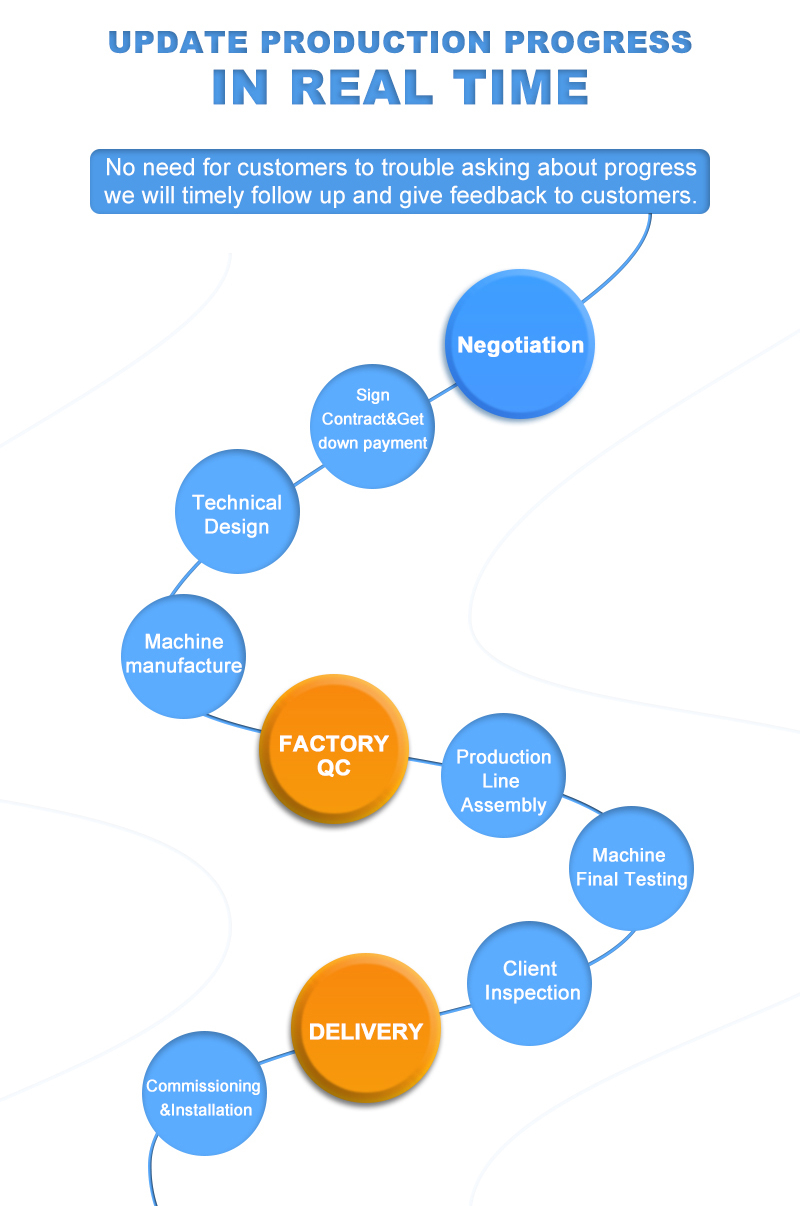

Q: Can we visit your factory?

Sure. We located in Zhangjiagang city which is very near Shanghai. For overseas customers, you can fly to Shanghai Pudong International Airport. We can pick you up in the Airport. (or Hongqiao International Airport. ) We also provide visit online by video.

Q: How can we get the exact price of plastic machine?

Contact us with the products size, shape, annual quantity and photo if possible. We can recommend our machine models with quotation.

Q: Do you provide any spare parts with machine?

Yes, we offer all necessary spare parts before shipment.(contact us for packing list )

Q: How about your after-sale service ?

We offer manual instruction and engineer training before loading,after shipment we provide 24 HRS online support, video technical support or field installation assist.

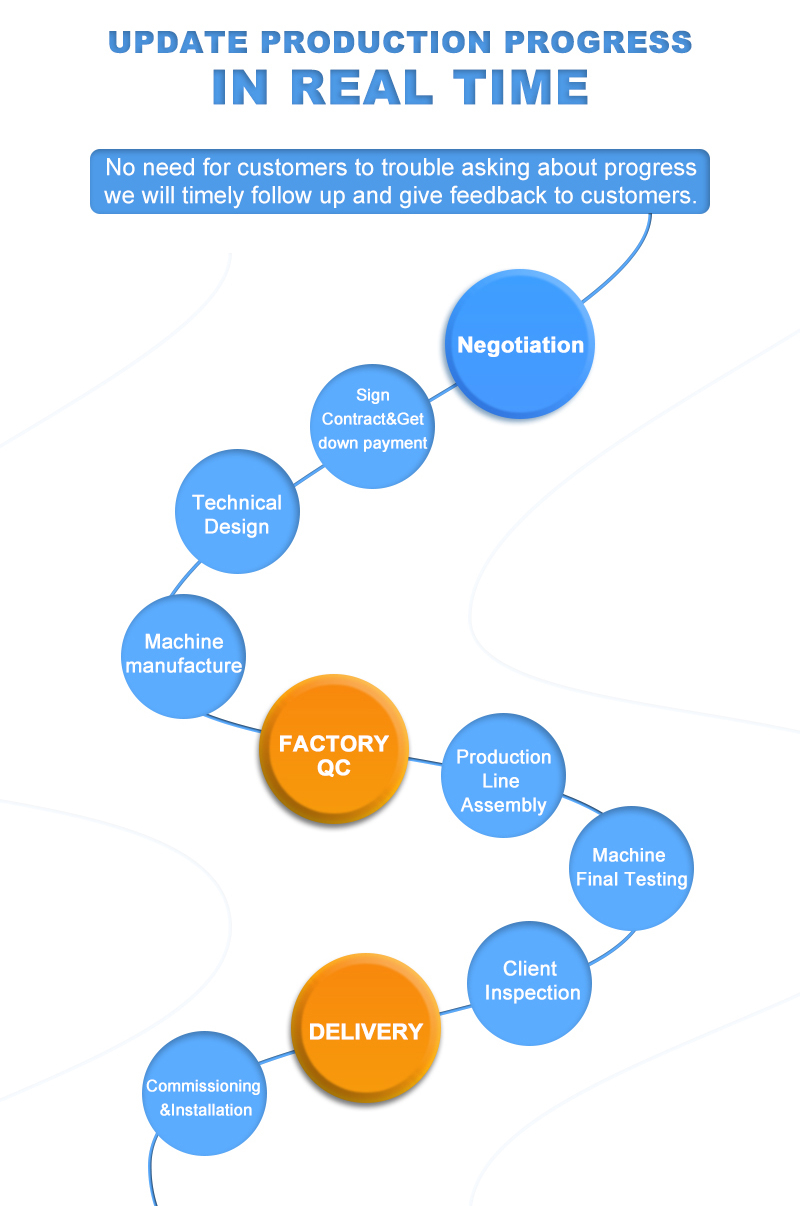

Q: What is the lead time?

For customized machine, it takes about 45-60 days after deposit. For stock machine, fast shipment. ( The actual production cycle will vary according to the degree of customization.)

Q: What is the warranty period for your machine ?

12 months warranty for components and technical support .

Q: Do you provide custom machines?

Most of our machines are customized. Our goal is efficiency and stable performance. We design the machines according to customers products to meet customer' needs.

Q: How can we install the machine when it arrives?

We can send experienced technicians to customer's country for guiding the installation and commission the machine, also train the customer's employees.

Q: What's the advantage of SINOTECH?

We provide customers with turnkey projects. Including plant design, plastic machine and mold installation, debugging, also we can source the auxiliary equipments for customers. We can ship the full set of machines after testing in our factory. It will save a lot of cost and time.