PVC powder is throwed into the inlet by manual, where a high-speed mixer thoroughly mixes it to meet production standards. The qualified powder is then stored in a tank. This vertical mixing mill can mix different formulations as required. During extrusion, the material is fed into the screw for melting and flow. The extruded melt is cut into granules, which are collected by a blower and transported to a cooling unit. After cooling and screening, qualified granules are collected and stored in a hopper.

How does this line work?

① Powder mixing system ➜ ② Material storage tank ➜ ③ Extrusion system ➜ ④ Granulation system ➜ ⑤ Drying system ➜ ⑥ Cooling system ➜ ⑦ Pellet collection tank

Powder mixing system

High-speed mixer can mix PVC powder and additives. The mixed raw materials will be sent to the cooling blender to decrease temperature before going to the next procedure. The mixing speed of high-speed mixer is adjustable according to different formulations’ requirements.

Material storage tank

It can storage enough mixed raw materials, and screw loader will conveying the materials to top tank of extruder.

Extrusion system

The extruder screw&barrel customized according to necessary formulations with Europe Standard. All electrical components of the machine are imported brands and equipped with soft-start protection to ensure more stable production and long life.

Granulation system

The PVC pelletizer machine equipped with a specially cutter blade axis, It will more convenient for dismantling and calibration.

Drying system

The blower and the tank can separate air and pellets, This process will cooling the pellets.

Cooling system

Vibrating screens can remove attached dust, screen particles of the appropriate size, and cool PVC particles evenly and quickly.

Pellet collection tank

The SS storage tank is for finished pellet storage. 1T(default) or 2T as opitional.

• The screw&barrel meets European export standards and can provide stable plasticizing production for 24 hours a day.

• The screw&barrel material is 38CrMoAlA with 0.5mm nitriding depth.

• The pneumatic components used are all from top international brands, ensuring stable and clean air quality, which extends the machine's lifespan and makes production more stable and reliable.

• The electronic components we installed are all imported brands, suitable for 24-hour uninterrupted production. Quality bring more time for production.

• The machine includes PID temperature control, and we also support customization of HMI and PLC to achieve intelligent production.

FAQ

Q: Can we visit your factory?

Sure. We located in Zhangjiagang city which is very near Shanghai. For overseas customers, you can fly to Shanghai Pudong International Airport. We can pick you up in the Airport. (or Hongqiao International Airport. ) We also provide visit online by video.

Q: How can we get the exact price of plastic machine?

Contact us with the products size, shape, annual quantity and photo if possible. We can recommend our machine models with quotation.

Q: Do you provide any spare parts with machine?

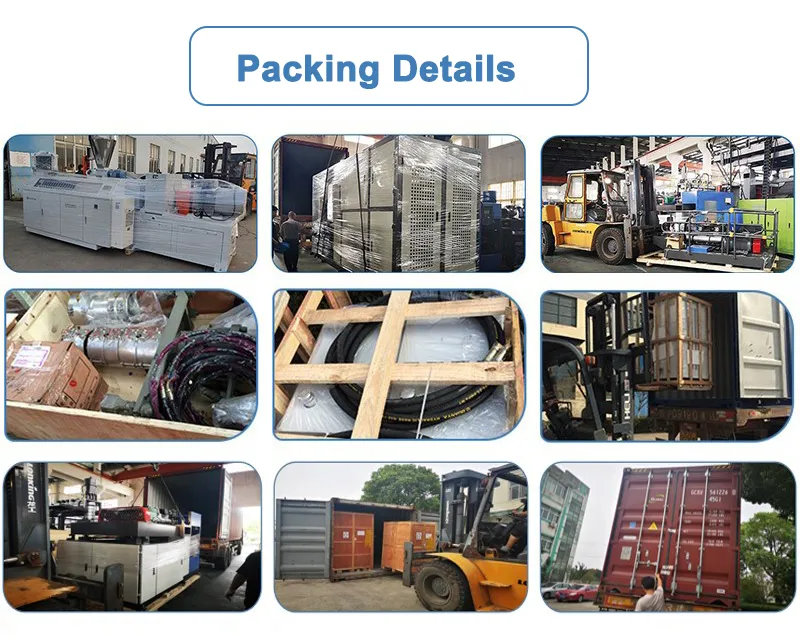

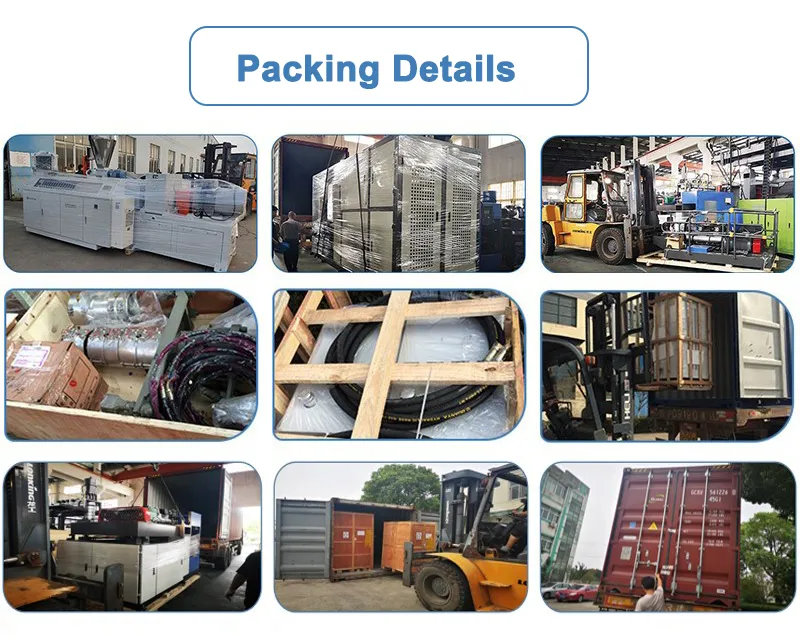

Yes, we offer all necessary spare parts before shipment.(contact us for packing list )

Q: How about your after-sale service ?

We offer manual instruction and engineer training before loading,after shipment we provide 24 HRS online support, video technical support or field installation assist.

Q: What is the lead time?

For customized machine, it takes about 45-60 days after deposit. For stock machine, fast shipment. ( The actual production cycle will vary according to the degree of customization.)

Q: What is the warranty period for your machine ?

12 months warranty for components and technical support .

Q: Do you provide custom machines?

Most of our machines are customized. Our goal is efficiency and stable performance. We design the machines according to customers products to meet customer' needs.

Q: How can we install the machine when it arrives?

We can send experienced technicians to customer's country for guiding the installation and commission the machine, also train the customer's employees.

Q: What's the advantage of SINOTECH?

We provide customers with turnkey projects. Including plant design, plastic machine and mold installation, debugging, also we can source the auxiliary equipments for customers. We can ship the full set of machines after testing in our factory. It will save a lot of cost and time.