Product Introduction

The 1000L Plastic Big Barrel Big Containers Plastic Pallets Blow Molding Machine is engineered for the production of large plastic containers such as 1000L HDPE drums, plastic pallets, and IBC tanks. This versatile machine offers high-speed production capabilities, with the ability to handle 450kg/hr plasticizing capacity. Ideal for industries such as chemical storage, logistics, and industrial packaging, the machine can produce large containers and pallets with precise molding and multi-layer extrusion options. With advanced parison control technology, it ensures uniformity and optimal material distribution.

Designed for heavy-duty use, the STD-1000L/2000L series blow molding machine is perfect for manufacturers who require large volumes of plastic containers and industrial pallets with superior strength and durability.

Product Features

Large-Scale Production: This machine can produce up to 16-18 IBC tanks per hour and 15-17 plastic pallets (1000x1000mm) per hour, making it ideal for high-demand production environments.

Flexible Die-Head Configurations: The machine comes with a 45L accumulator die head to produce 1000x1000mm pallets. The die head can be swapped to produce smaller drums or other container sizes, offering great flexibility in production.

High Plasticizing Capacity: With a plasticizing capacity of 450kg/hr, this machine can efficiently process HDPE, HMWHDPE, PP, and other materials for large container production.

Product Advantages

Energy-Efficient and Fast: The machine uses servo-drive motors and MOOG parison control systems for optimal energy use while maintaining high-speed production, reducing overall operational costs.

Durability and Precision: Constructed with Aluminum 7075 molds and Beryllium Copper, the machine ensures precise molding and enhanced cooling efficiency, increasing mold life and reducing maintenance.

Customizable Production: The machine can be configured with single, double, or triple die heads, allowing manufacturers to produce containers in a variety of sizes and configurations, tailored to meet specific market needs.

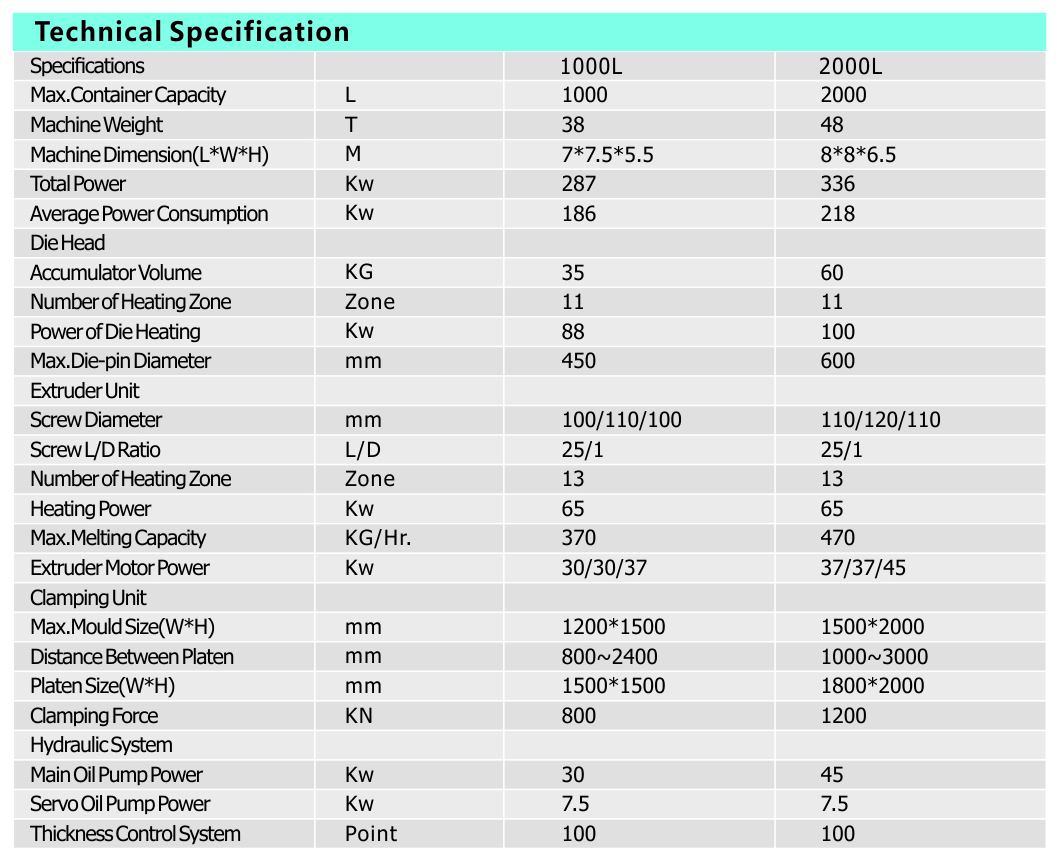

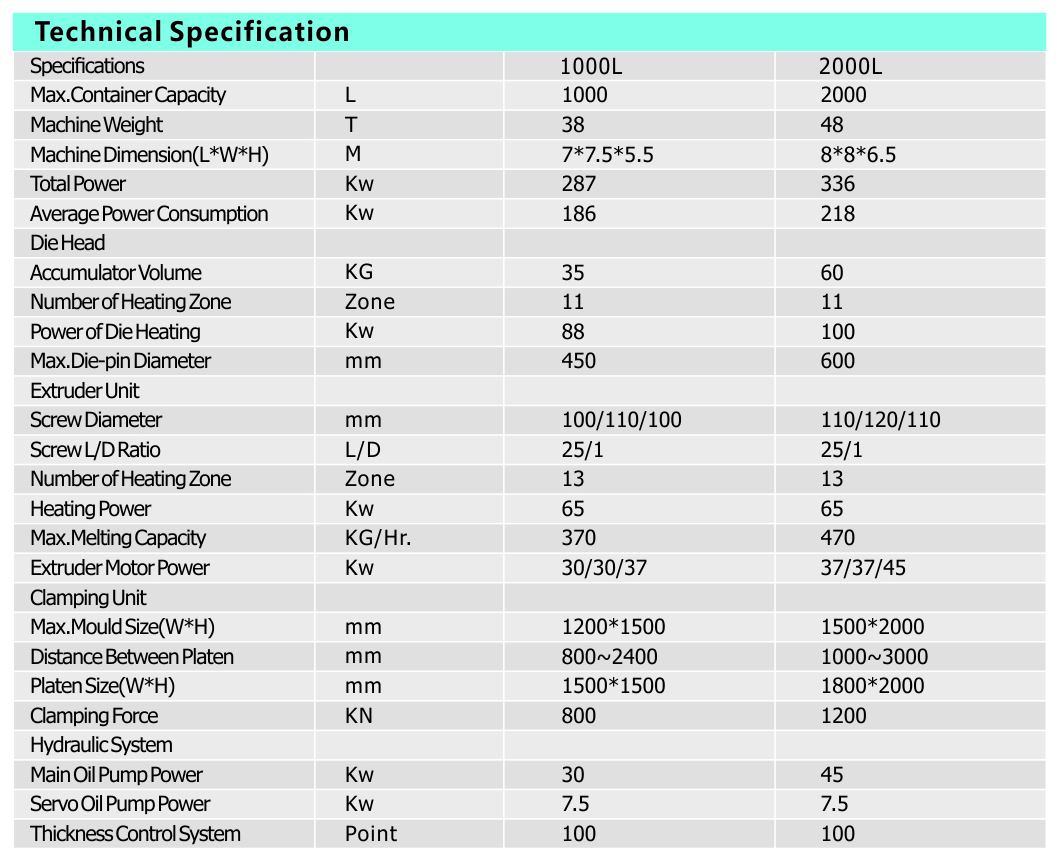

Product Parameters

Why Choose Us?

At SINOTECH Machinery Co., Ltd., we have over 20 years of experience in delivering cutting-edge blow molding technology. Our 1000L Plastic Big Barrel Big Containers Plastic Pallets Blow Molding Machine is built for high performance and durability, ensuring that your production needs are met with maximum efficiency. Whether you are looking to produce large containers, plastic pallets, or IBC tanks, our machines provide the flexibility and reliability needed to scale up your production while maintaining low operational costs.