Product Description

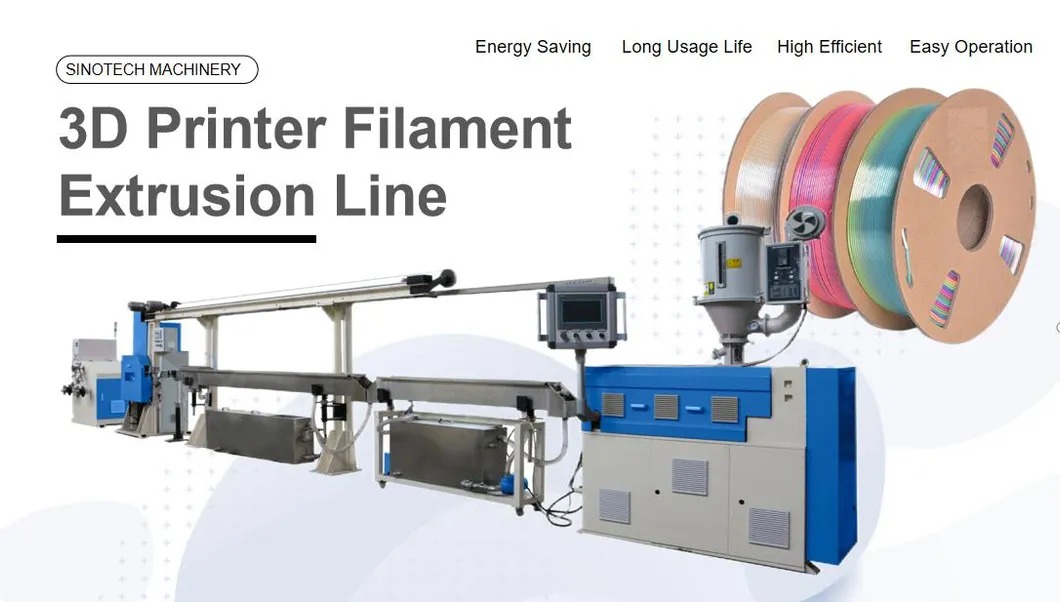

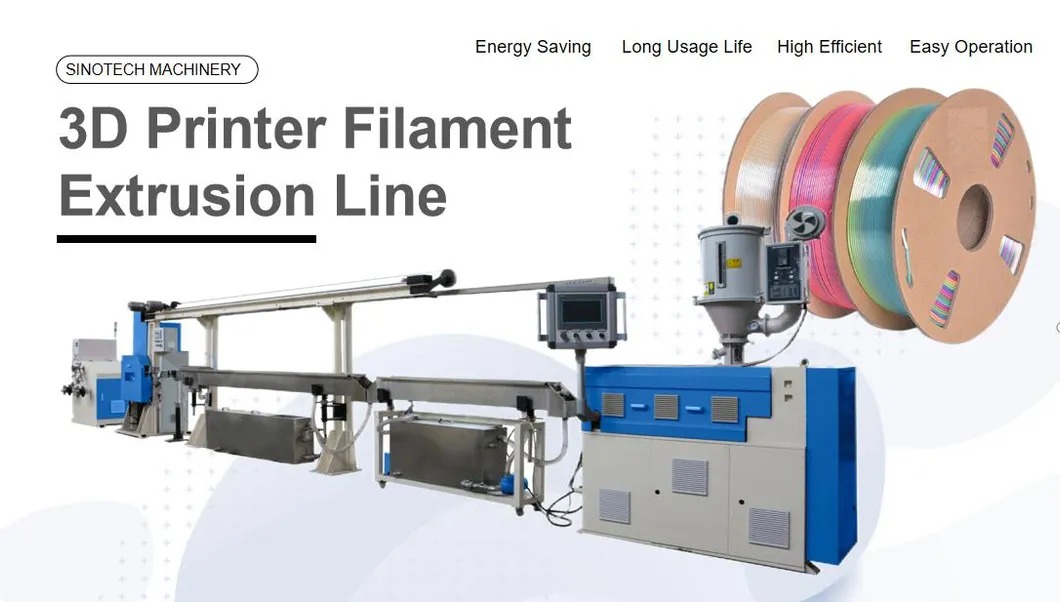

Sino-Tech New Design Small Scale Laboratory 3D Printer Filament Production Line

Professional 3D Filament Extruder Supplier has been used by designers, engineers and scientists to produce the disposable mechanical products and model, and it is already widely used in health care, education, toys, building, automobile, electronics, and anime field.

Feature:

Information of the PLA, PA Nylon, PC ,and HIPS and ABS filaments,

1. ABS filament process temperature is 230-260° C,melting point is 230° C

2. PLA 3D printer filament is 210-235°C, melting point is 200°C

3. PVA temperature for printer is 180°C-200°C.Melting point is 200°C.

4. PA Nylon temperature for printer is 220°C-250°C.Melting point is 260°C

5. PC temperature for printer is 230°C-250°CMelting point is 260°C.

6. HIPS filaments temperature for printer is 160°C-220°C,Melting point is 230°C.

Detailed information :

Production Process: Raw plastic material is mixed and fed into the extruder. The extruder shapes the material using a mould, and the formed product goes through a hot water tank for further shaping. It then enters a cooling water tank to cool down. A laser gauge is used to measure the diameter of the product for quality control purposes. The traction machine pulls the product, while an accumulator stores the wire. Finally, the winding machine automatically winds the product.

Production Line Features:

1. The production line is equipped with a high precision Siemens PLC control system.

2. The entire line operates with servo motor and precision gearbox drive, ensuring stable extrusion, smooth running, and accurate speed control.

3. The FLD production line incorporates an Automatic Feedback System for improved efficiency.

4. All devices on the line are centrally controlled through a computer screen, enabling easy and convenient operation.Detailed information :

Production Process: Raw plastic material is mixed and fed into the extruder. The extruder shapes the material using a mould, and the formed product goes through a hot water tank for further shaping. It then enters a cooling water tank to cool down. A laser gauge is used to measure the diameter of the product for quality control purposes. The traction machine pulls the product, while an accumulator stores the wire. Finally, the winding machine automatically winds the product.

Production Line Features:

1. The production line is equipped with a high precision Siemens PLC control system.

2. The entire line operates with servo motor and precision gearbox drive, ensuring stable extrusion, smooth running, and accurate speed control.

3. The FLD production line incorporates an Automatic Feedback System for improved efficiency.

4. All devices on the line are centrally controlled through a computer screen, enabling easy and convenient operation.

| SN-25 Mini 3D printer filament Extrusion |

| Control System | PLC touch screen |

| Feed back control system | Between laser gague and screw speed |

| power consumption and power supply | 6KW Triphase 380/50 Hz |

| Raw Material | ABS/PLA/PETG/WPC |

| Filament Diameter: | 1.75 mm. / 3 mm. |

| Diameter tolerance | 0.05mm |

| Output Capacity | 2.5-3kg/h |

| Hopper drier: one set | 12KG Volume |

| Main Motor Power | 2.2KW |

| Max. Heating Temp. | 300degree |

| Heating Power: | 3KW |

| Machine Size | 3000*600*1800mm |

| Machine net weight | 480KG |

| Machine gross weight | 450KG |

| Screw | Single screw Extruder |

| Diameter | 25 mm. |

| L/D | 28:1 |

| Raw material | 38CrMoAlA |

| surface treatment | Nitrogenization and polished |

| Inner surface treatment | Nitrogenization and polished |

| Barrel |

|

| Material | 38CrMoAlA |

| Inner surface treatment | Nitrogenization and polished |

| The nitride layer thickness | 0.5~0.7 mm. |

| The surface hardness | HV850~940 |

| Heating control zone | 6 |

| Mould, a connecting body | 1 |

| Water tank | 1 SET |

| Raw material | 304# |

| Size | 1200x100x120mm |

| Single Axis Laser gauge unit | 1 SET |

| Model NO | LST-25 |

| Measurement range | 0-25mm |

| Fouor wheel puller | 1 SET |

| Rated Power | 0.37KW |

| Control style: | Inverter control |

| Diameter of wheel | Φ80 mm |

| Material of wheel | PU rubber coated |

| Single Auto winder | 1 SET |

| Applicable spool size | Max.diameter : 300 mm. Width:100 mm. |

| Power | 0.37W |

| Control style | inverter control |

| Drive | Timing belt control |

| machine frame | SS steel machine frame |

Q: Can we visit your factory?

Sure. We located in Zhangjiagang city which is very near Shanghai. For overseas customers, you can fly to Shanghai Pudong International Airport. We can pick you up in the Airport. (or Hongqiao International Airport. ) We also provide visit online by video.

Q: How can we get the exact price of plastic machine?

Contact us with the products size, shape, annual quantity and photo if possible. We can recommend our machine models with quotation.

Q: Do you provide any spare parts with machine?

Yes, we offer all necessary spare parts before shipment.(contact us for packing list )

Q: How about your after-sale service ?

We offer manual instruction and engineer training before loading,after shipment we provide 24 HRS online support, video technical support or field installation assist.

Q: What is the lead time?

For customized machine, it takes about 45-60 days after deposit. For stock machine, fast shipment. ( The actual production cycle will vary according to the degree of customization.)

Q: What is the warranty period for your machine ?

12 months warranty for components and technical support .

Q: Do you provide custom machines?

Most of our machines are customized. Our goal is efficiency and stable performance. We design the machines according to customers products to meet customer' needs.

Q: How can we install the machine when it arrives?

We can send experienced technicians to customer's country for guiding the installation and commission the machine, also train the customer's employees.

Q: What's the advantage of SINOTECH?

We provide customers with turnkey projects. Including plant design, plastic machine and mold installation, debugging, also we can source the auxiliary equipments for customers. We can ship the full set of machines after testing in our factory. It will save a lot of cost and time.