High speed Yoghurt bottle milk bottle blow molding moulding Machine

Product Introduction

The High Speed Yoghurt Bottle Milk Bottle Blow Molding Machine is designed to produce high-quality milk bottles, yogurt bottles, and a variety of other plastic containers. The STBII-3L series blow molding machine is capable of producing 1L to 3L bottles, with high-speed production and the flexibility to handle multiple die-head configurations, including double station 6 die-head, 4 die-head, and 2 die-head options. With a cycle time of just 16 seconds, this machine can produce up to 2700 bottles per hour, offering fast turnaround times and high-volume production.

The machine is specifically built for industries that require efficient production of milk bottles, yogurt bottles, household containers, detergent bottles, and more. It can be easily customized to meet specific production needs, offering a cost-effective solution for large-scale manufacturing.

Product Features

High-Speed Production: With a cycle time of 16 seconds, this blow molding machine can produce up to 2700 bottles per hour, making it perfect for high-demand production.

Flexible Die-Head Configurations: The machine is equipped with a double station 6 die-head system, but can also be customized with 2, 4, or 3 die-head systems for different bottle sizes, ranging from 150ml to 3L.

Versatile Applications: This machine is ideal for producing various types of bottles, including milk bottles, yogurt bottles, detergent bottles, cosmetic containers, and lubricant oil bottles, making it highly adaptable to different industry needs.

Product Advantages

Customizable Production: The machine’s interchangeable die-heads allow it to produce bottles in various sizes, from small yogurt bottles to larger milk containers, offering flexibility in production.

Energy Efficiency: With the high-efficiency servo drive system and MOOG parison control system, the machine optimizes material usage, reducing waste and improving wall thickness distribution, while also reducing cooling time.

Durability: The use of Aluminum 7075# molds with Beryllium Copper or 4Cr13 stainless steel ensures high mold durability, superior cooling performance, and long operational lifespans, contributing to reduced maintenance costs.

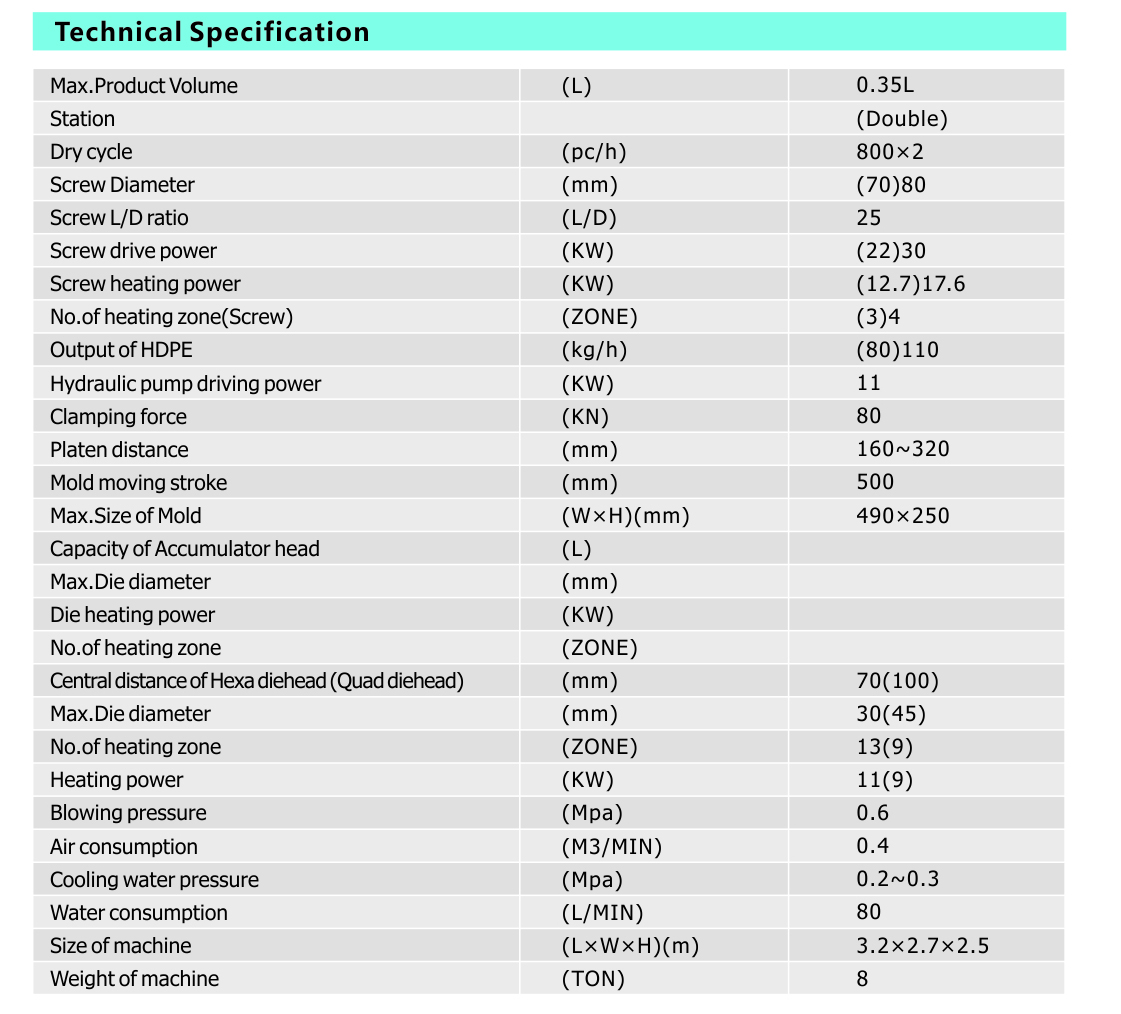

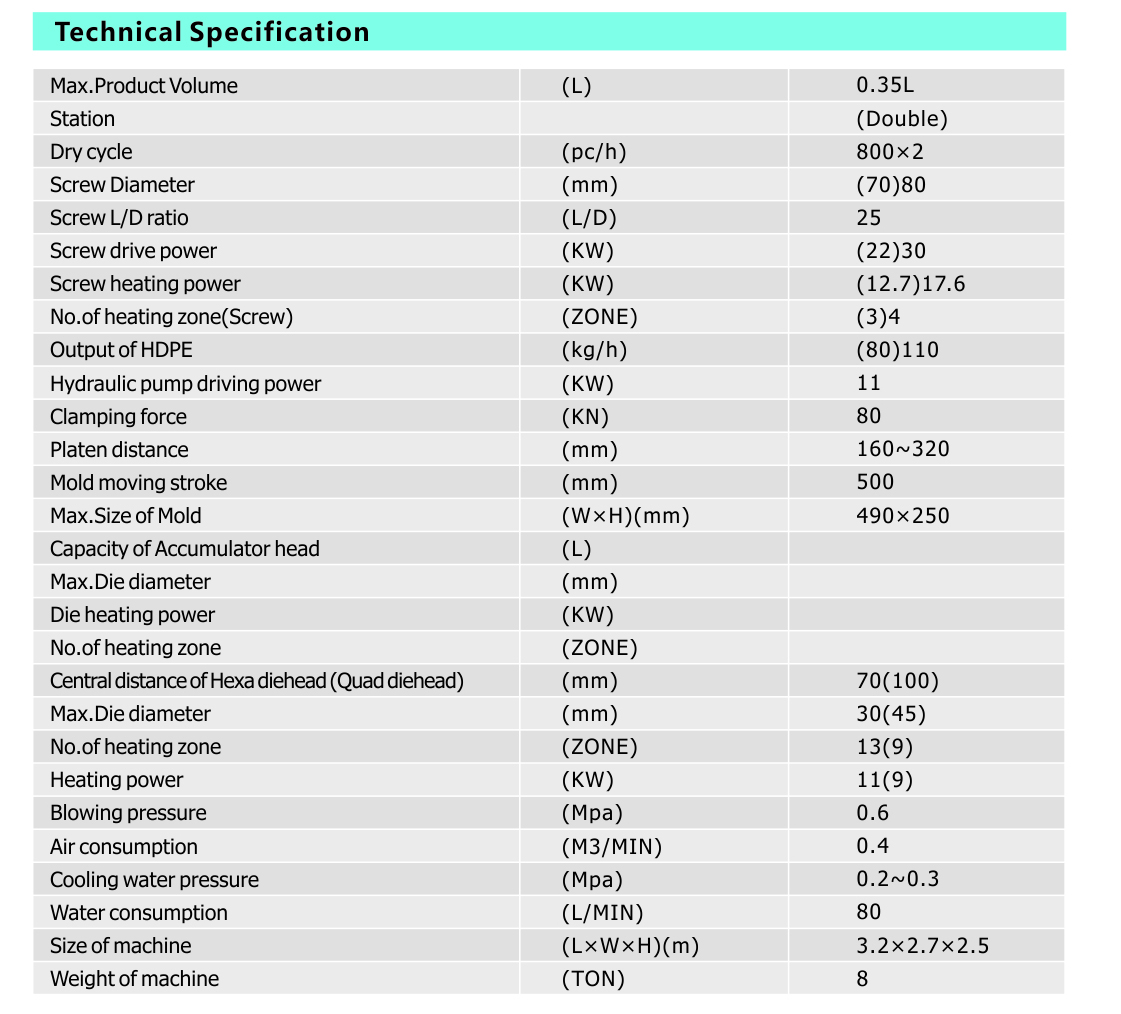

Product Parameters

Product Application

Product Application

The High Speed Yoghurt Bottle Milk Bottle Blow Molding Machine is ideal for the production of various plastic bottles, including:

Yogurt Bottles: Perfect for producing lightweight, reliable yogurt containers used by dairy manufacturers.

Milk Bottles: High-speed production of milk bottles, offering precise and uniform quality.

Household Bottles: Used for manufacturing detergent bottles, shampoo bottles, and household cleaners.

Cosmetic Bottles: The machine is adaptable to produce a wide range of cosmetic and personal care packaging, including lotions and creams.

FAQ

Q: What types of bottles can this machine produce?

A: This machine can produce milk bottles, yogurt bottles, detergent bottles, cosmetic containers, lubricant oil bottles, and more, with sizes ranging from 150ml to 3L.

Q: How fast is the production cycle?

A: The machine features a cycle time of 16 seconds, allowing for the production of up to 2700 bottles per hour.

Q: Can the machine be customized for different bottle sizes?

A: Yes, the machine is highly customizable with interchangeable die-head systems ranging from single to six die-heads, making it adaptable to different production needs.

Product Application

Product Application