PVC sheet extrusion is a way to make flat sheets from raw PVC. It uses a plastic extrusion line to shape the PVC. The process uses heat and pressure to make strong, even sheets. These sheets are used in many industries. The plastic extrusion line keeps the temperature and pressure steady. This helps the sheets stay the same thickness. SINOTECH Machinery Co., Ltd. also has plastic recycling lines. They also offer blow molding machines for other production needs.

PVC sheet extrusion uses heat and pressure. It makes flat and strong sheets from raw PVC. These sheets are used in many industries.

The process has several steps. First, materials are fed into the machine. Then, they are melted and mixed. Next, the melted PVC is shaped with a die. After that, calendering makes the sheets smooth. Cooling comes next. Finally, the sheets are cut.

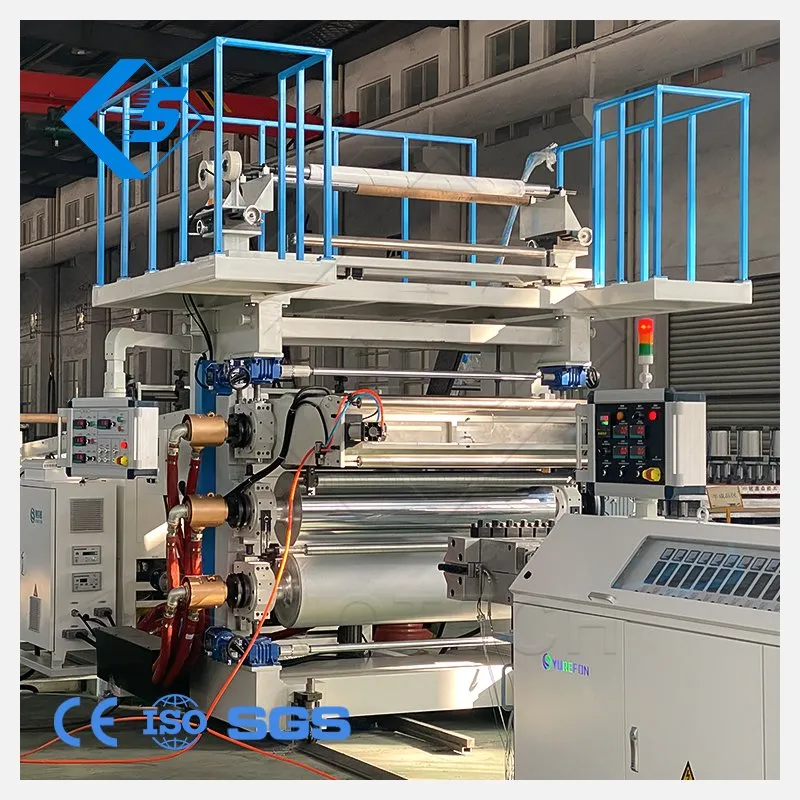

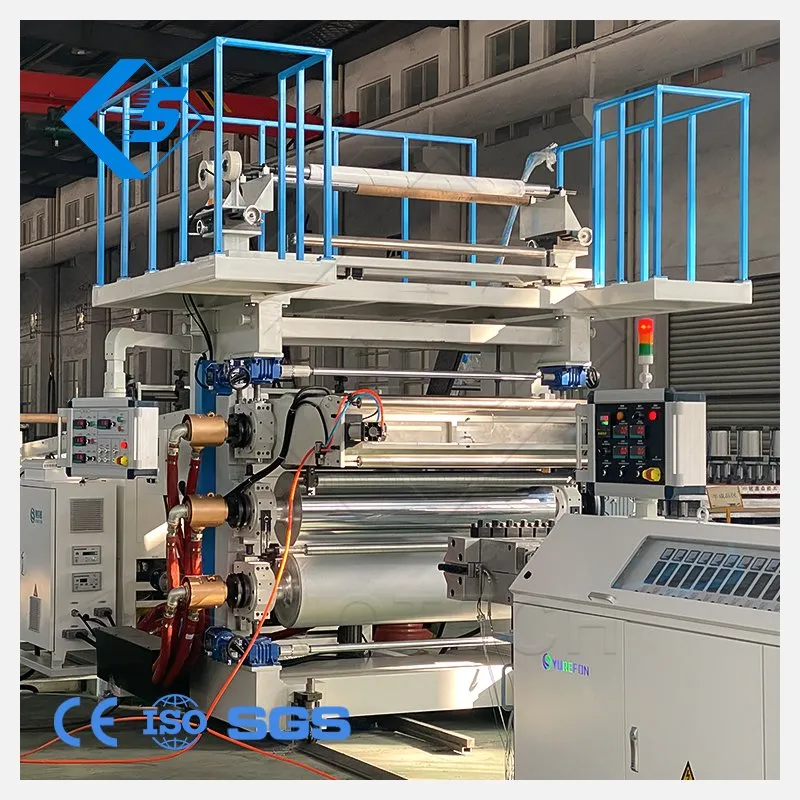

Different machines help in the process. Extruders melt and push the PVC. Calender rolls make the sheets even. Cooling units lower the temperature. Cutting systems slice the sheets. These machines keep sheets smooth and even.

Factories use rigid or flexible PVC. They add other materials to make the sheets better. The sheets are made for buildings, packaging, decoration, and ads.

Sheet extrusion is fast. It gives good quality control. It can recycle materials. But workers must watch the process closely. This helps avoid defects.

PVC Sheet Extrusion Basics

What Is Sheet Extrusion

Sheet extrusion uses a plastic extrusion line to make flat sheets from raw plastic. The machine heats the plastic and pushes it through a die. This forms a long, flat sheet. The extrusion line controls how thick and wide the sheets are. Operators use this process to get smooth and even sheets. First, plastic pellets go into the extruder. The extruder melts and mixes the plastic. The melted plastic goes through the die and becomes a flat sheet. Calender rolls make the sheet smooth and the right size. Cooling units make the sheet hard before it is cut. This process is fast and makes many sheets quickly. Factories use sheet extrusion to make lots of products.

Sheet extrusion is important in making plastic products. It helps companies make sheets for many things with great accuracy.

Purpose and Uses

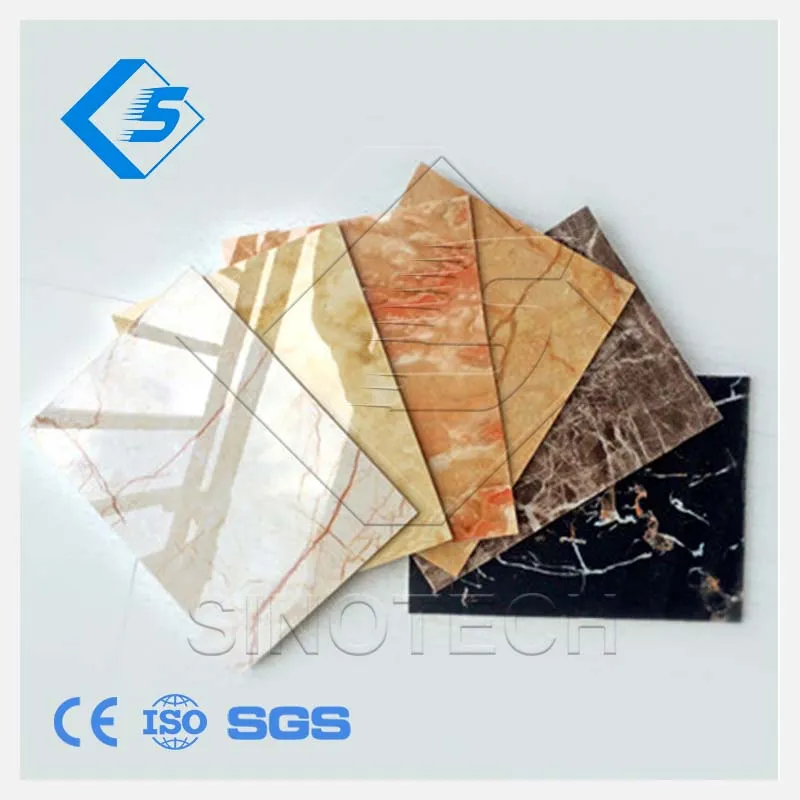

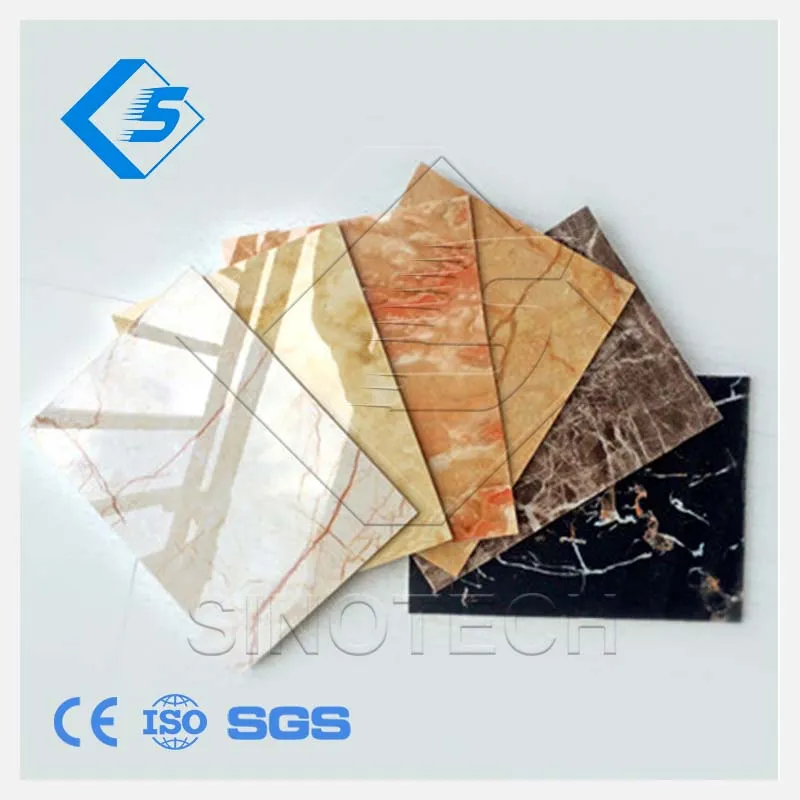

Sheet extrusion is used in many fields. Companies use it to make things for building, home design, packaging, and ads. The extrusion line makes sheets for walls, ceilings, and fake marble. It also makes hard and soft films for packaging. Many banners for ads are made with PVC sheet extrusion. The extrusion line checks that each sheet is high quality. SINOTECH Machinery Co., Ltd. has machines for different materials and thicknesses. Their machines also work with blow molding and recycling lines. This gives more ways to make products. Sheet extrusion helps companies make strong, light, and useful products.

Industry | Common Uses of Sheet Extrusion |

Construction | Wall panels, ceiling panels |

Home Decoration | Artificial marble sheets, profiles |

Packaging | Rigid and flexible films |

Advertisement | Banners, display boards |

Plastic sheet extrusion helps factories work fast and make a lot. Companies use these lines to make the same products for many uses.

Sheet Extrusion Process

The sheet extrusion process changes raw PVC and additives into flat sheets. This process uses special machines to make sure the sheets are good and look the same. Every step in the sheet extrusion line helps make strong sheets for many industries.

Material Feeding

Operators start by putting raw material into the extruder. The material has PVC resin, stabilizers, plasticizers, and other additives. The plastic extrusion line uses a hopper to move these materials into the screw extrusion process. Feeding the material evenly helps the machines work well and make sheets that look the same.

Tip: Using good raw material and careful feeding helps stop problems in the finished sheet.

Melting and Mixing

Next, the sheet extrusion process melts and mixes the material. The extruder heats the PVC between 160°C and 200°C. Operators must keep the temperature under 200°C so the PVC does not break down. PVC can start to break down even below 160°C, so the temperature window is small. Heat stabilizers and additives help protect the material during this step.

Mixing well is needed for good sheet extrusion. The process uses hot and cold mixing to do this. The table below shows how these mixing methods work together:

Mixing Technique | Key Parameters and Effects |

Hot Mixing | - Temperature: 110-120°C (discharge at 120°C)

- Time: 7-12 minutes

- Makes plastic mix and spread evenly

- Additives are mixed in steps for best results |

Cold Mixing | - Cools material to about 40°C

- Uses cooling water at 13-15°C

- Stops moisture from coming back

- Makes sheets more even and better quality |

Sheet Extrusion Line Steps

The sheet extrusion line uses careful steps to make flat sheets. The process uses special machines to control each part:

Put the material into the extruder, where it melts and moves forward.

The melted material goes through a screen changer to take out dirt.

A gear pump keeps the pressure and flow steady.

A static mixer mixes the melt to make it even.

The melted material goes through a flat sheet die to make the sheet.

Cool the sheet with a roll stack that controls temperature and pressure.

Cut the cooled sheet to size, roll it up, or send it for more work.

These steps help the sheet extrusion line make sheets that look the same and are high quality for many uses.

Calendering and Cooling

After the sheet comes out of the die, it goes to calendering and cooling. Calender rolls help shape and finish the sheet. These rolls press the melted material into a flat sheet. Each roll is usually hotter and faster than the last one, which helps shape the sheet.

Calender rolls set thickness by changing the rolling bank of material between rolls.

The rolls make the sheet thinner step by step until it is the right size.

Special steel rolls stop bending and keep the sheet flat.

Embossing rolls can make patterns on the sheet.

Laminating stations can add extra layers to the surface.

Stripping rolls take the sheet off the calender and help control shrinking and flatness.

The cooling frame makes the sheet hard. Cooling the sheet right is important for keeping its shape and surface. The plastic extrusion line uses cooling water and air to get the sheet to the right temperature before cutting.

Cutting and Finishing

The last step in the sheet extrusion process is cutting and finishing. The cooled sheet goes to the cutting system, where it is cut to the right length and width. Some sheet extrusion lines roll up the sheets, while others stack them for shipping.

Operators check the sheets for quality, looking at thickness, surface, and flatness. The machines make sure every sheet meets strict rules. Some lines add extra finishing, like coating or printing, to meet special customer needs.

Note: Cutting and finishing the sheets well helps save material and make better products.

The sheet extrusion process needs careful control at every step. Calender rolls, cooling frames, and smart control systems help every sheet meet industry rules. SINOTECH Machinery Co., Ltd. has many kinds of extrusion machines, including recycling lines and blow molding machines, for different needs. Their plastic extrusion line works well for construction, packaging, home decoration, and ads.

Plastic Extrusion Line Equipment

Extruder Types

Plastic extrusion machines use different extruder types for PVC. The single-screw extruder is the most common. It is good for making simple sheets. Twin-screw extruders do harder jobs. They mix in additives or recycle materials. Each extruder type helps melt and mix PVC. SINOTECH Machinery Co., Ltd. has both types of extruders. These machines make a lot of sheets and work well. They are great for big factories.

Die and Calender Rolls

The flat sheet die shapes melted PVC into a flat sheet. This die has a heated chamber and lips that change thickness. The extrusion die uses a restrictor bar and a special manifold. These keep the flow even across the sheet. Operators can move the die lips by hand or with machines. This helps make the sheet the right size. Calender rolls come after the die. These rolls are shiny and have their own heat controls. The rolls press the sheet to the right thickness and finish. The table below shows important design features:

Component | Key Design Features |

Flat Sheet Die | Heated chamber, adjustable lips, restrictor bar, special manifold, manual or automatic thickness control |

Calender Rolls | Three chrome-plated rolls, individual temperature control, pressure loading, various roll arrangements |

These features help the machines make sheets that are smooth and even.

Cooling and Haul-off Units

Cooling units are important in the extrusion process. Cooling rollers or water tanks stop the sheet from warping. They help keep the sheet flat. The haul-off unit pulls the sheet at a steady speed. This helps control how thick and smooth the sheet is. Big lines use moving haul-off units and air ring cooling. These designs stop wrinkles and keep the sheet the same. Automation in these units helps control the process and makes it faster.

Cooling systems keep sheets flat and correct.

Haul-off units make sure sheets are smooth and even.

Automation makes production faster and better.

Cutting Systems

Cutting systems finish the extrusion process. Automated CNC cutting machines work quickly and cut sheets to the right size. These machines need less work from people and make fewer mistakes. They can run all day and make more sheets. Cutting with precision means less waste and more even products. CNC systems can cut many shapes and sizes for different needs. Smart software in these machines helps watch and control the process. This makes the whole line work better.

Automated cutting systems help factories save time, cut waste, and make better products.

Plastic extrusion machines from SINOTECH Machinery Co., Ltd. have these smart features. Their machines help in construction, packaging, and home decoration. Other products, like blow molding machines and recycling lines, give more choices for factories.

Materials and Additives

PVC Types

PVC sheet extrusion uses different materials for different jobs. Rigid PVC is good for wall panels and boards in buildings. Flexible PVC is used for packaging films and soft sheets. Each material gives special features to the finished sheet. Factories pick the right material for what the sheet will do. Rigid material makes sheets strong and steady for building. Flexible material lets sheets bend and shape for packaging. SINOTECH Machinery Co., Ltd. has machines for both rigid and flexible material. Operators can change materials to fit what customers want. The material choice changes how strong, colorful, or smooth the sheet is.

PVC Type | Main Use Cases | Key Properties |

Rigid PVC | Wall panels, ceiling boards | Strong, stable, hard |

Flexible PVC | Packaging films, soft sheets | Bendable, soft, clear |

Tip: Picking the right material helps the sheet work well and meet customer needs.

Additives in Plastic Extrusion

Additives help the main material work better in PVC sheet extrusion. Factories use stabilizers to keep the material safe from heat. Plasticizers make the material softer and easier to shape. Colorants give the sheet the right color for home or ads. Lubricants help the material move easily through the machine. Fillers can make the material cost less or feel different. All additives mix with the main material before going into the extruder. SINOTECH Machinery Co., Ltd. makes machines that mix material and additives well. Operators watch the amounts to keep the sheets high quality.

Common additives in PVC sheet extrusion are:

Heat stabilizers

Plasticizers

Colorants

Lubricants

Fillers

Blow molding machine lines use similar materials and additives for bottles and containers. The right mix of material and additives makes sheets strong, smooth, and reliable. Customers can ask for special mixes for their own projects.

Note: Watching the material and additives closely helps stop problems and keeps the sheets the same every time.

Benefits, Challenges, and Applications

Advantages of Sheet Extrusion

Sheet extrusion has many good points for factories today. This process makes flat sheets that are always the same thickness. The sheets also have smooth surfaces. Factories can make a lot of sheets very fast. This helps when many people need these products, like in building and packaging. The process lets workers control how wide and thick the sheets are. They can change the settings for different products. Sheet extrusion can use recycled material too. This helps companies care for the environment.

Sheet extrusion lines from SINOTECH Machinery Co., Ltd. use smart controls. These controls help keep the quality high and waste low.

Other good things about sheet extrusion are:

It works with both rigid and flexible PVC.

You can add colors, patterns, or special finishes.

It costs less when making lots of sheets.

It works well with blow molding and recycling.

Common Challenges

Sheet extrusion also has some problems. Workers must watch the temperature and pressure closely. If it gets too hot, the PVC can break down. This can make the sheets have problems. If the material is not fed or mixed well, bubbles or rough spots can happen. Keeping the machines clean and working right is important. Sometimes, the raw material changes and this can hurt the final product. Factories must check every step to stop waste and machine stops.

Some common problems are:

Sheets can bend or be too thick in some spots.

Marks or color lines can show up on the surface.

Cooling can go wrong and make the sheet not flat.

Using recycled material can be hard.

Training workers and checking the process often helps stop these problems. This keeps the sheet extrusion process steady.

Extrusion Lines Applications

Sheet extrusion lines are used in many areas. The process helps make things for building, home design, packaging, and ads. SINOTECH Machinery Co., Ltd. makes extrusion lines for each type of job.

Main ways people use sheet extrusion lines:

Packaging: Food boxes, films, and sheets for products.

Construction: Wall panels, ceiling boards, and shapes.

Automotive: Light panels and inside car parts.

Home Decoration: Fake marble sheets and pretty panels.

Advertisement: Banners, display boards, and signs.

Industry | Common Products Made by Sheet Extrusion |

Packaging | Rigid and flexible films, trays |

Construction | Wall panels, ceiling sheets |

Automotive | Interior panels, protective covers |

Home Decoration | Decorative sheets, artificial marble |

Advertisement | Banners, sign boards |

Plastic extrusion lines can help companies sell to many countries. New ideas in recycling and better materials help this area grow. SINOTECH Machinery’s machines, like blow molding and recycling lines, help customers make more products.

Companies that want to work faster and make better products often pick new sheet extrusion lines for their factories.

The sheet extrusion process uses special machines to make PVC sheets. Workers watch every step, like feeding material and cutting sheets. This helps keep the sheets good quality. Knowing how the process and machines work helps factories make more sheets. Many businesses use extrusion lines for packaging, building, and decorating homes. SINOTECH Machinery Co., Ltd. also sells blow molding machines and recycling lines. Companies should try to make the sheet extrusion process work as well as possible for the best results.

Picking the right extrusion line helps make better products and saves time.

FAQ

What is the main purpose of PVC sheet extrusion?

PVC sheet extrusion makes flat and strong sheets. These sheets are used in many places. Factories use them for building, packaging, and home design. The process keeps the sheets smooth and the same thickness.

How does a plastic extrusion line control sheet quality?

Operators set the temperature and pressure on the machines. Calender rolls and cooling units help keep sheets flat. These tools make sure the sheets are even. SINOTECH Machinery has smart systems for better quality.

Which materials can be used in sheet extrusion lines?

Factories use both rigid and flexible PVC. They also add things like stabilizers, plasticizers, and colorants. Some machines use recycled materials too. SINOTECH Machinery works with many types of materials.

What other products can SINOTECH Machinery make?

SINOTECH Machinery makes blow molding machines and recycling lines. These machines help make bottles, containers, and recycled plastic items. They are used for packaging and everyday products.

Where are PVC sheets commonly used?

PVC sheets are found in wall panels and ceiling boards. They are also used for banners and packaging films. Many businesses use these sheets for building, ads, and home design.

Tip: Check out SINOTECH Machinery’s product page to learn more about extrusion lines and other equipment.