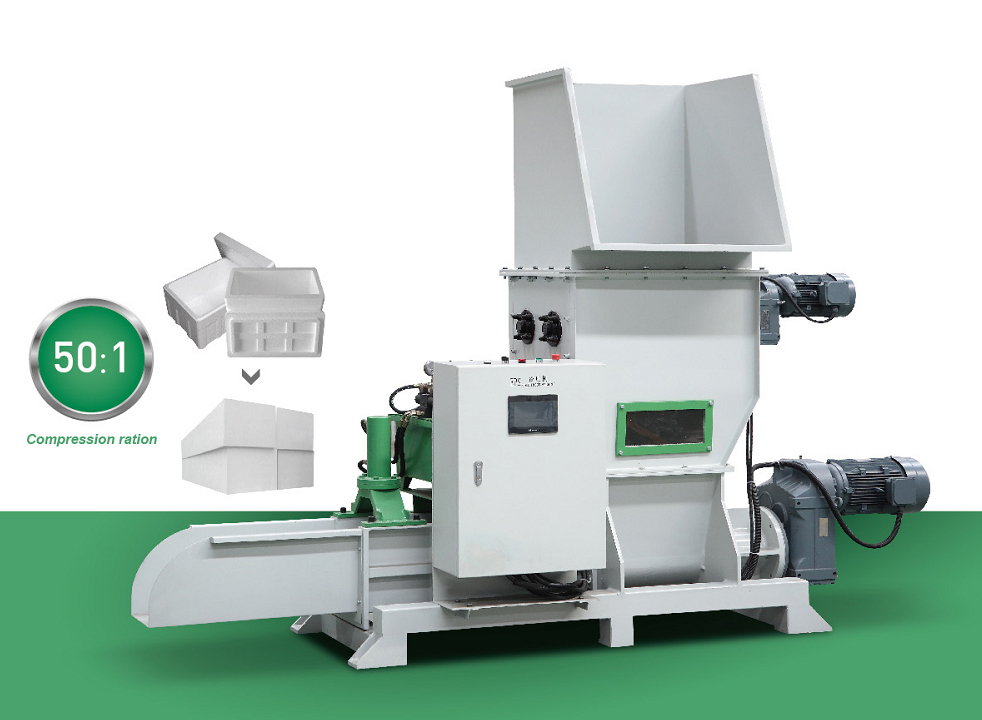

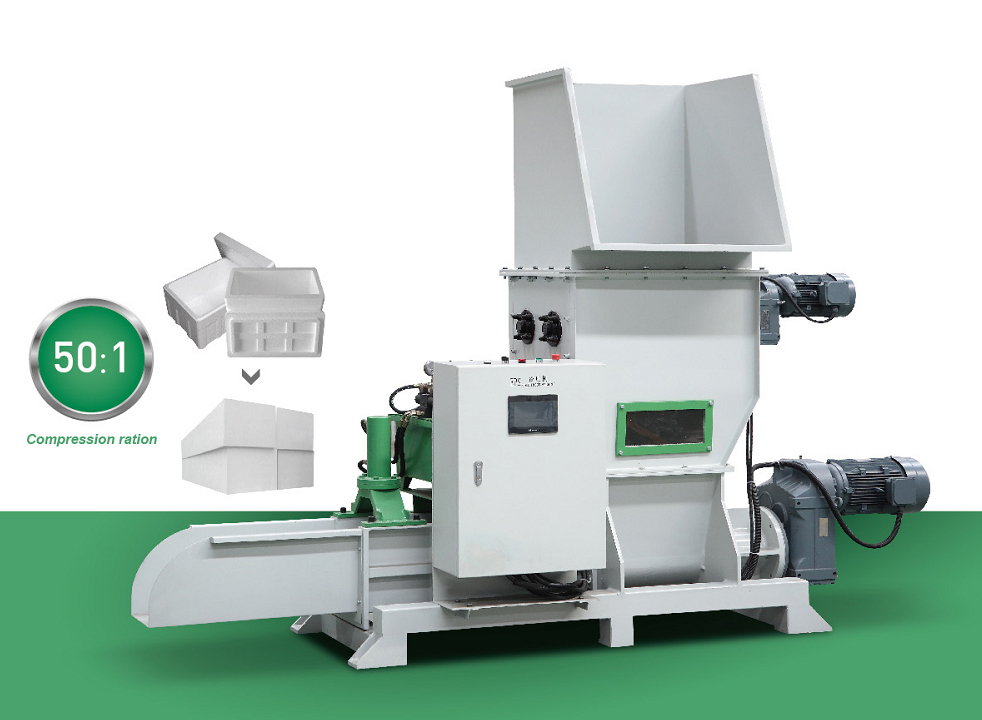

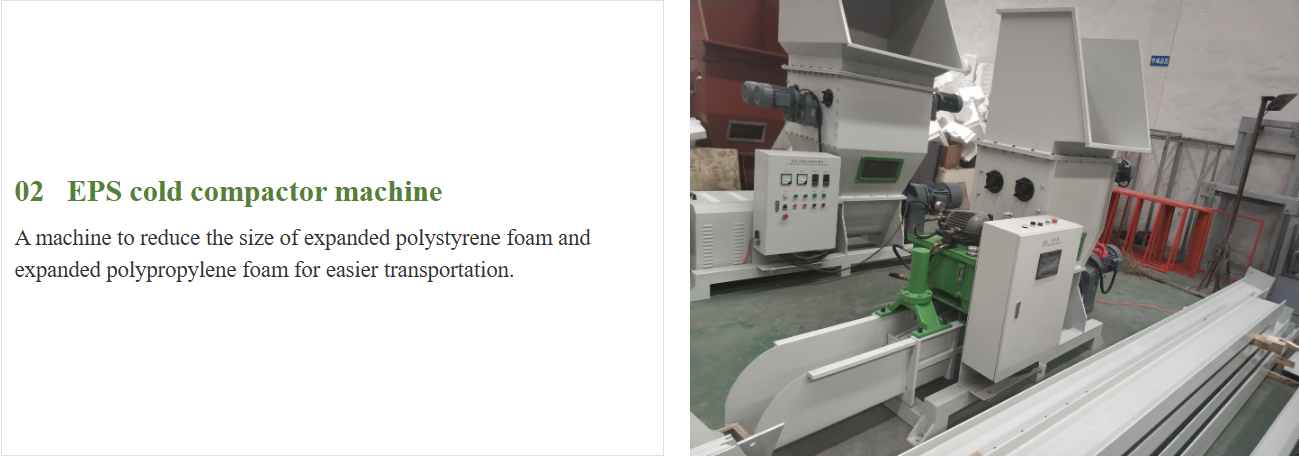

Hot Sale EPS Foam Cold Compactors Machine

Most polystyrene products are currently not recycled due to the lack of incentive to invest in the compactors and logistical systems required. Due to the low density of polystyrene foam, it is not economical to collect. However, if the waste material goes through an initial compaction process, the material changes density from typically 30kg/m3 to 350kg/m3 and becomes a recyclable commodity of high value for producers of recycled plastic pellets.

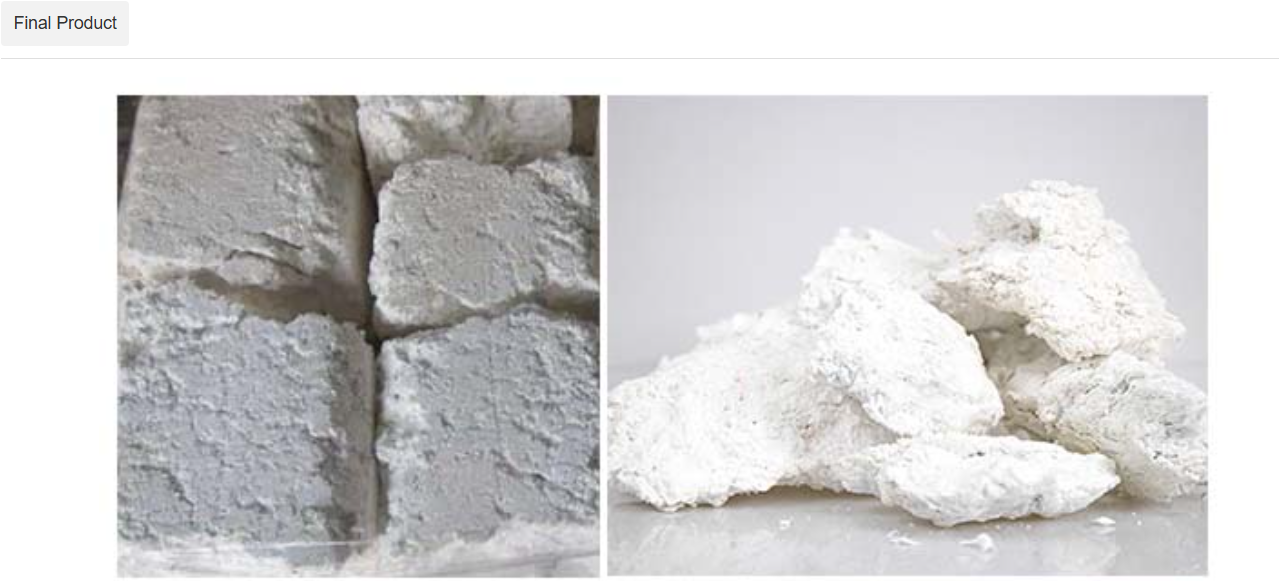

The EPS foam compressor generates a pressure-compressed force to compress foam by the screw spiral rotation,then make the foam scrap into an EPS foam compression blocks. Our Greenland brand foam compressor machines, can reach max up to 50 times compression ratio,greatly reduce the storage and transportation costs of EPS foam, are good choice for EPS foam recycling.

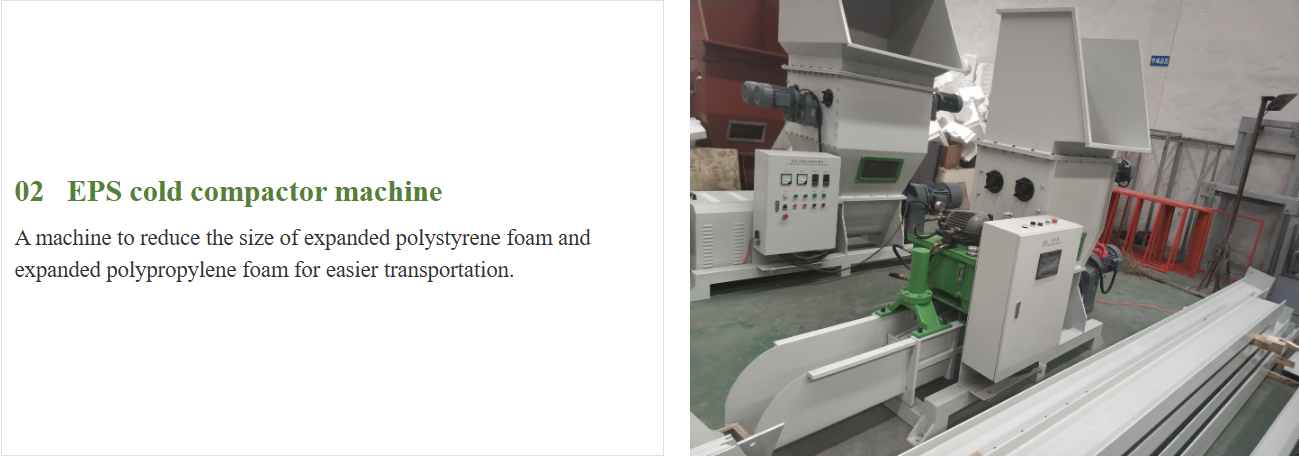

Suitable Products:

It is suitable for EPP EPE XPS PUR EVA EPS plastic foam and polystyrene foam, such as foam box, EPS foam board, EPS foam fast food box, etc.

Main features:

1. Capacity:50-300kg per hour.

2. As a kind plastic foam densifier, it is applied to a wide usage to compress and hot melting machine EPS EPP EPE XPS PUR EVA.

3. The foam compactor could be used in many places, such as super market, schools, hospitals, small-sized warehouse, retail stores, and seafood markets...

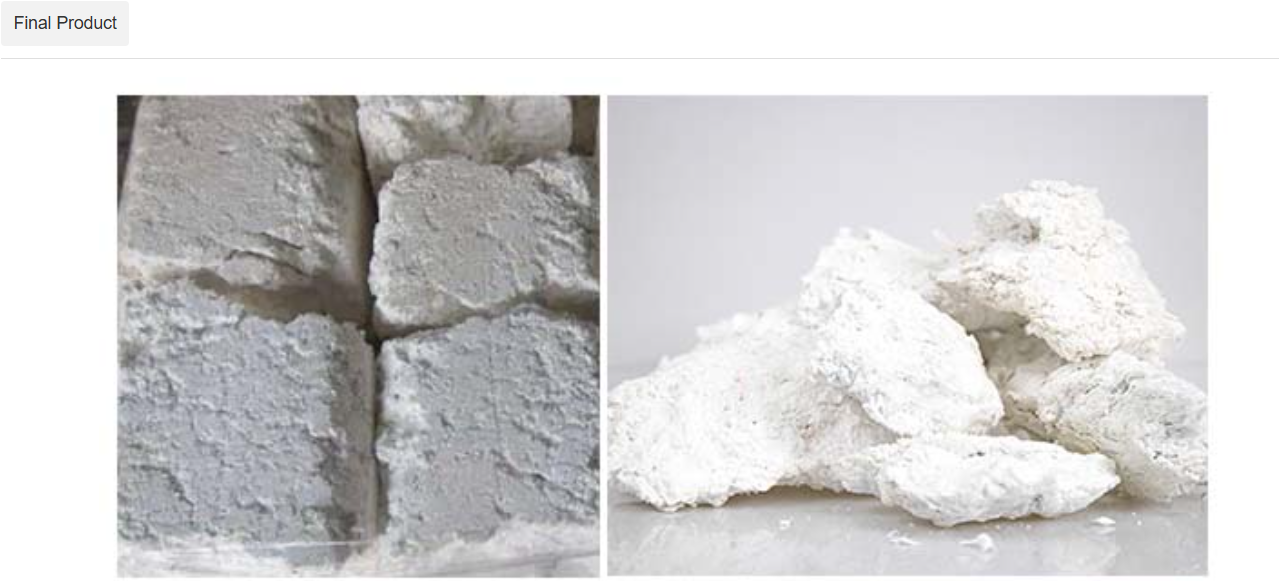

4. The foam compactor press the plastic foam from big to small size high efficiently, the compression ratio could arrive at 1:30~1:50, the compressed material block density could be 350kg/m³, and then it is easy to transport and recycle for next step.

5. The foam compactor has excellent performance, compacting dimension, low noise, easily and convenient operating and maintenance…

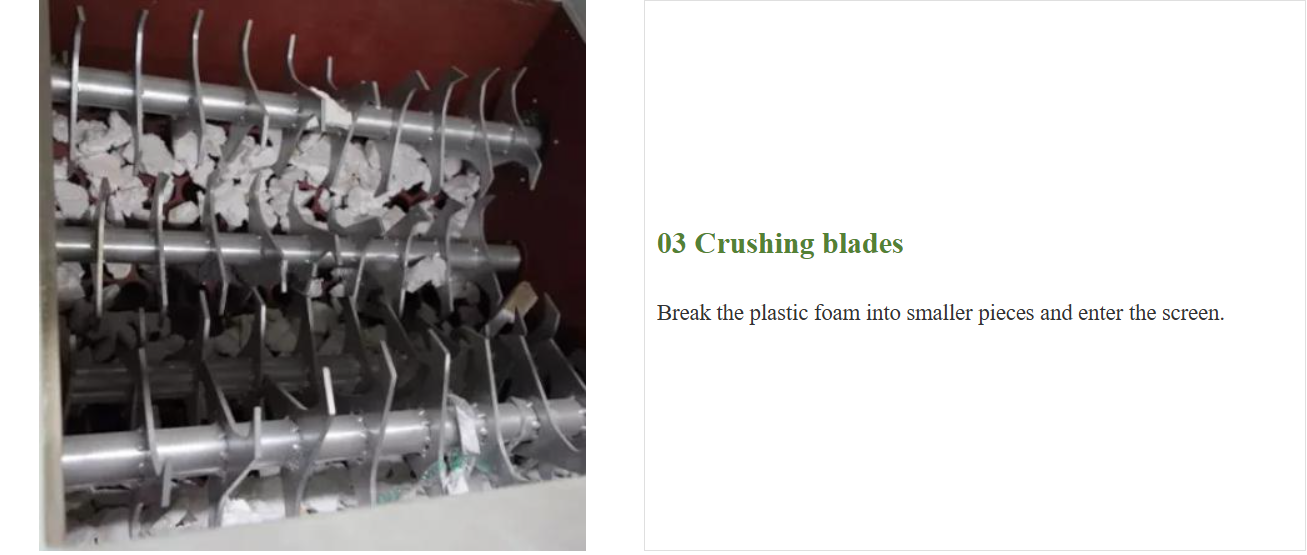

6. Ingenious designed feeding hopper, one aspect it could prevent the material jumps out when crushed, the aspect it could also to collect all material into one point to push the material direction down and helping to feed the material into extruder.

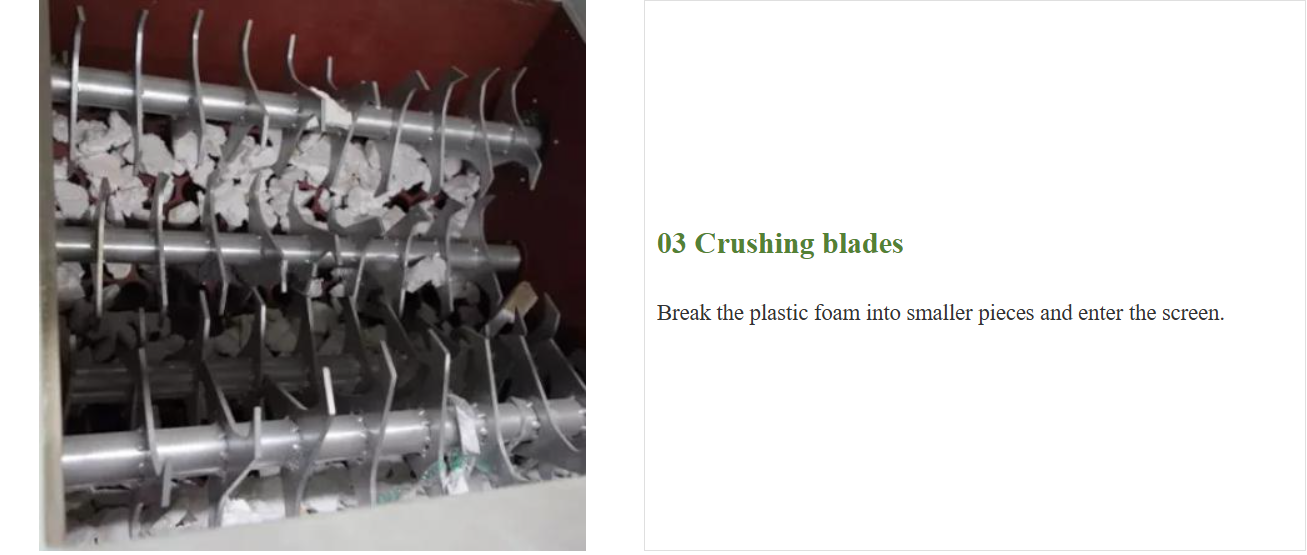

7. Exquisite structure of blades, especially experienced designing to the angles of all blades, which could guarantee high efficient crushing performance with high capacity, but also could press the crushed material blocks into the extruder to increase the capacity of whole machine.

8. Compacting screw and hydraulic pressing, which makes the compression process high efficient and good performance. All parts compacted into one machine, saving cost, low energy consumption, small space covering, which makes the machine to be portable type.

9. The foam compactor is controlled by PLC automatic controlled, easily operating, stable working performance.

10. The block is usually compressed to be 250*250mm or 380*380mm block.

| Model | GL-CP-50 | GL-CP-100 | GL-CP-200 | GL-CP-300 |

| Capacity | 50kg/h | 100kg/h | 200kg/h | 300kg/h |

| Screw diameter | Φ138mm | Φ290mm | Φ350mm | Φ410mm |

| Inlet size | 615mm*500mm | 1000mm*600mm | 1000mm*600mm | 1500*600mm |

| Screw rotation speed | 30rpm | 36rpm | 36rpm | 36rpm |

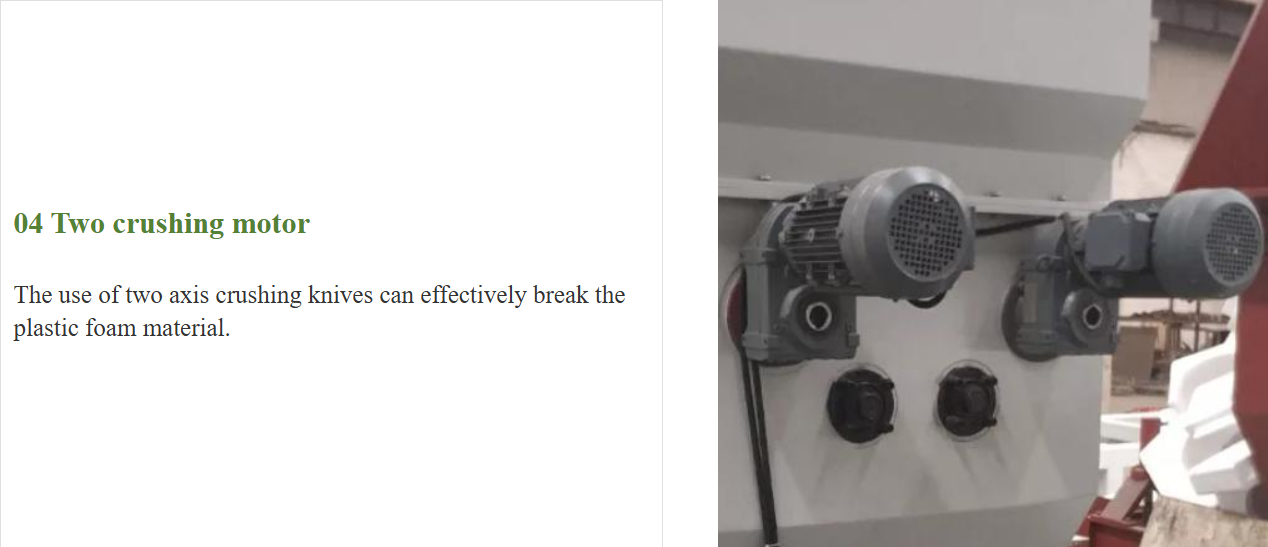

| Crusher blade quantity | 10pcs | 2 crushing shafts | 4 crushing shafts | 4 crushing shafts |

| Crusher rotation speed | 100rpm | 120rpm | 120rpm | 120rpm |

| Main motor | 5.5kw | 11kw | 15kw | 22kw |

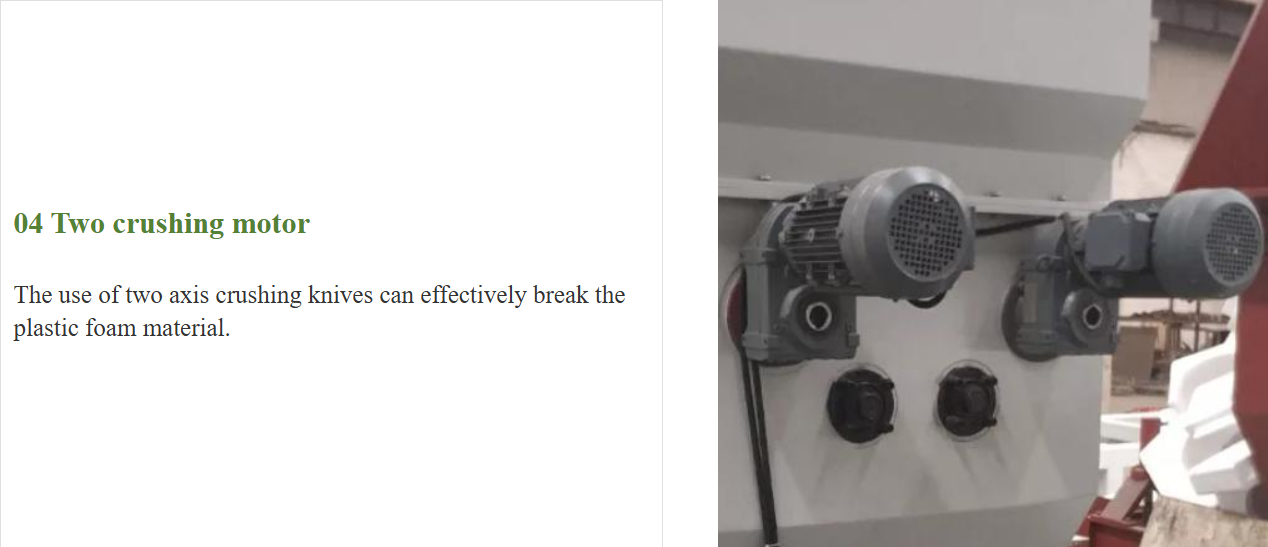

| Crusher motor | 1.1kw | 2.2kw*2pcs | 2.2kw*4pcs | 2.2kw*4pcs |

| Hydraulic pump |

| 1.5kw | 1.5kw | 2.2kw |

| EPS Block size | 100*100mm | 250*250mm | 380*380mm | 380*380mm |

| Dimension | 1200*1000*1400mm | 3000*1300*2100 mm | 4800*1500*2500mm | 4960*4480*4430 mm |

Working principle:

The twin shaft are two parallel shafts with blades, they running in different rotation direction. Each shaft has blades and driven by the gear box, to crushing the EPS material then the material will get throught the sreen into the barrel. The material will be processed by the high speed rotary screw to the barrel, then the high press to reduce the volume density.

For the environment:

1.EPS is uniquely recyclable - all manufacturing waste can be fully reprocessed as can the products at end-of-life.

2.EPS is comprised of 98% air and therefore only 2% polystyrene making it a highly efficient use of raw material.

3.Although EPS is derived from a non-renewable resouce - oil, it represents less than 0.1% of crude oil usage.

4.As EPS is highly energy efficient - the energy saved over the lifetime of an insulation panel.

Q1:What about the payment terms?

A1:Always 30% down payment as deposit,70% balance pay before shipping.

Q2:What about the payment way?

A2:TT,L/C at sight or Alibaba trade assurance.

Q3:If you can extend the guarantee time?

A3:Yes.Our guarantee time is 24 months.Double times of other factory because we have strong confidence for our product.

Q4:If you will send engineer coming to our factory to install and test the machines?

A4:Yes,Every set of machine we will send professional engineer to your factory and help installation and test the machines for you.

Q5:If you have CE,SGS,ISO certificate?

A5:Yes,except these,if you also need other certificates,we also can help to apply.

Q6:If we buy your machines, can you offer us wear-out spare pats?

A6:Yes,We provide our high quality machine 2 years' guarantee,and we will also offer you 2 years wear-out spare parts for free.

Once your machines broken or doesn't work within 2 years and you can't solve it, firstly, we will try to help you to find problems from your words description by phone or other communication tools. Secondly, if the phone solutions still not work, our engineers will go to your factory to solve it. Meanwhile, they will teach you the related experiences for fixing.

Q7:The voltage,if you can design according to our request?

A7:Yes.