A plastic extrusion line turns raw plastic into useful things. This process runs all the time in factories. It helps make pipes, sheets, and shapes we use every day. Many industries depend on this method. The market for plastic extrusion machines is growing each year. By 2032, it could reach USD 10.08 billion. There is a lot of demand in Asia-Pacific.

Metric | Value (USD Billion) | Period | Additional Info |

Market Size (2023) | 6.8 | 2023 | Slight increase from 2022 |

Projected Market Size (2032) | 10.08 | 2032 | Forecasted growth |

Compound Annual Growth Rate | 5.00% | 2024-32 | CAGR over forecast period |

Asia-Pacific Market Share | 45.8% | 2022 | Largest regional share, led by China |

SINOTECH Machinery is a leader in this area. They make strong extrusion lines. They help bring new ideas to plastic manufacturing around the world.

Plastic extrusion lines change raw plastic into things like pipes and sheets fast. They do this in a way that saves time and energy. The system uses heat and pressure to shape plastic. Shaped dies help make the plastic into the same shapes every time. Many industries use these shapes for different products. There are different machines for different jobs. Single-screw extruders are good for simple products. Twin-screw extruders work for more complex products. Plastic extrusion helps save money. It uses less energy and cheaper molds. It can also use recycled materials. The quality stays high. Picking a trusted supplier like SINOTECH Machinery is important. You get reliable machines and strong support. You also get smart technology.

Plastic Extrusion Line Overview

Definition and Function

A plastic extrusion line is a system that works all the time. It changes raw thermoplastic resin into finished plastic products. The system uses heat and pressure to melt the plastic. Then, it pushes the melted plastic through a shaped die. This makes long shapes with the same cross-section, like pipes and sheets. Factories use plastic extrusion to make many items fast. The plastic extrusion line helps many industries by making plastic parts that look the same. It can handle different thermoplastics. Sometimes, extra steps like cutting or coiling are added for special needs.

The main job of a plastic extrusion line is to turn raw plastic pellets or granules into finished products. First, workers mix plastic with additives to get the right properties. The extruder heats and melts the plastic. A screw moves the melted plastic forward. The plastic goes through a filter to remove impurities. Next, the material moves through a die. The die shapes it into the profile needed. Cooling systems make the plastic solid. Machines cut or coil the product if needed. This process helps factories make plastic items like pipes and sheets quickly.

SINOTECH Machinery has over 20 years of experience. They design and build plastic extrusion lines. The company helps customers all over the world. They give technical support from planning to after-sales service.

Key Components

A plastic extrusion line has many important parts. Each part does a special job in the process:

Plastic Extruder: The extruder is the main part of the system. It has a heated barrel and a screw that turns. The extruder melts and mixes the plastic. It pushes the plastic forward with steady pressure.

Adapter Plate: This part connects the extruder to the die. It holds the breaker plate. The breaker plate changes the flow from spinning to straight.

Transition Plates: These plates guide the melted plastic from the adapter plate to the die. They help shape the flow and control the size of the product.

Die: The die shapes the melted plastic into the profile needed. It has a straight part called the die land and die lips. These give the product its final shape and surface.

Spider Plate: This plate is used for hollow products. It spreads the plastic around the die. It supports the mandrel to make hollow centers.

Flow Dividers: In co-extrusion lines, flow dividers keep different materials apart. They stay separate until they leave the die together. This helps bonding and stops blockages.

Cooling System: After shaping, the plastic goes through cooling baths or rollers. This step makes the product solid and keeps its shape.

Post-Processing Equipment: Machines cut, coil, or punch the finished plastic. These steps get the product ready for shipping or more use.

Component | Main Function |

Plastic Extruder | Melts and pushes plastic forward |

Adapter Plate | Connects extruder to die, changes flow direction |

Transition Plates | Shapes and guides plastic flow |

Die | Forms the final shape of the product |

Spider Plate | Creates hollow centers in products |

Flow Dividers | Separates materials in co-extrusion |

Cooling System | Solidifies and stabilizes the product |

Post-Processing | Cuts, coils, or finishes the product |

Plastic extrusion lines use advanced technology for good results. Sensors, heaters, and cooling channels help control temperature and flow. This helps factories make complex and strong plastic products.

SINOTECH Machinery builds extrusion lines with quality and new ideas. The company sends its equipment to Southeast Asia, Europe, America, Africa, and Russia. Customers trust SINOTECH for reliable machines and good support.

Plastic Extrusion Process

Step-by-Step Process

The plastic extrusion process turns raw plastic into finished products. It uses a set of steps that are carefully controlled. This method is very important in many plastic factories. Each step helps make sure the product is good quality.

Material Preparation: Workers sort and dry the plastic pellets. Drying removes water from the pellets. This helps stop problems in the final product.

Feeding: The dry pellets go into the extruder through a hopper. The hopper lets the right amount of pellets into the machine.

Melting: The pellets move inside a barrel that is heated. A screw turns and makes heat and friction. This melts the plastic so it is even.

Mixing and Compression: The screw pushes and mixes the melted plastic. Additives like color or stabilizers are mixed in. This makes sure everything is blended well.

Filtering: The melted plastic goes through screens and a breaker plate. These remove dirt and keep the pressure steady for smooth flow.

Shaping: The plastic moves through a die. The die gives the plastic its shape, like a pipe or sheet.

Cooling: The shaped plastic goes into a cooling system. Water, air, or rollers make the plastic hard fast so it keeps its shape.

Finishing: Machines cut, coil, or punch the hard plastic. The finished pieces are ready to be packed or used more.

Quality control is important at every step. Workers check the raw plastic and watch the temperatures. They look at the finished product for color, size, and strength. Special machines like vision sensors help keep quality high. SINOTECH Machinery uses these tools to make sure every line makes good products.

Types of Plastic Extrusion

Factories use different types of extrusion for different jobs. Each type is good for certain uses.

Feature | Single Screw Extruder | Twin Screw Extruder |

Number of Screws | One | Two |

Mixing Efficiency | Moderate | High |

Self-Cleaning | Limited | Excellent |

Energy Consumption | Lower | Higher |

Complexity | Simple | Complex |

Application Scope | Basic extrusion tasks | Advanced compounding, mixing |

Single-Screw Extruder

This machine has one screw that turns inside a barrel. It is good for simple jobs like making pipes, films, and sheets. It is easy to use and saves energy. It works best with one kind of plastic. It does not mix as well as other types.

Twin-Screw Extruder

This machine has two screws that fit together. It mixes and blends plastic very well. It can handle tough or special plastics. It is used for jobs like making masterbatch or wood plastic composites. The screws can be changed easily. It also controls heat better.

Co-Extrusion

Co-extrusion uses two or more materials in one product. Each material goes through its own extruder. They join together in a special die. This makes products with layers, like barrier films or pipes with different insides and outsides. Co-extrusion lets each layer have its own best features.

High-Speed Extrusion

High-speed extrusion makes products faster but still good quality. SINOTECH Machinery uses special drives and controls for this. It saves energy and makes more products. This is good for big factories.

SINOTECH Machinery is a leader in extrusion technology. The company works on new ideas to make lines smart and efficient. Their machines can use many kinds of plastic, even recycled ones. SINOTECH also helps with recycling and less waste. This supports a circular economy for plastics.

The screw extrusion process is very important in plastic factories today. By picking the right type and using good controls, factories can make strong products for many uses.

Plastic Extrusion Machines

Machine Types

Factories use different plastic extrusion machines for many jobs. The most common types are single-screw extruders, twin-screw extruders, and ram extruders. Single-screw extruders have one screw that turns inside a hot barrel. They are good for simple jobs like making pipes and sheets. These machines cost less and are easy to fix. Twin-screw extruders have two screws that spin in opposite ways. They mix plastic better and can handle tough jobs. These machines are best for products that need to be very exact and even. Ram extruders use a piston to push plastic through a die. They work well with thick materials like ceramics or special rubbers.

The pe pipe extrusion production line is special in the industry. It uses new technology to make pipes that resist rust, chemicals, and hits. This line works fast and makes pipes very accurately. Workers like it because it is easy to use. The pe pipe extrusion production line can make many pipe sizes and types of joints. This makes it useful for lots of projects.

Machine Type | Key Features | Typical Use Cases |

Single-screw | Simple, efficient, low maintenance | Pipes, sheets, profiles |

Twin-screw | Superior mixing, handles complex plastics | Compounds, blends, specialty |

Ram extruder | High pressure, for high-viscosity materials | Ceramics, special rubbers |

PE pipe extrusion | Advanced tech, high precision, easy operation | Water, gas, industrial piping |

Auxiliary Equipment

Auxiliary equipment helps the main extrusion process and makes products better. Some important examples are:

Hopper dryers take water out of plastic pellets before use.

Vacuum loaders move raw plastic to the extruder by themselves.

Cooling tanks or rollers make the shaped plastic hard quickly.

Haul-off units pull finished products at a steady speed.

Cutting machines or winders get the product ready for packing or more work.

SINOTECH Machinery is a top company for plastic extrusion machines. They focus on new technology and strong quality checks. SINOTECH gives full help from start to finish. Customers get machines they can trust and easy use. The company cares about good products and happy customers, so people trust them all over the world.

Extrusion Products and Applications

Common Materials

Plastic extrusion uses many kinds of plastic to make products. Each type has special features for different jobs. The most used plastics are high-density polyethylene (HDPE), low-density polyethylene (LDPE), polypropylene (PP), and polyvinyl chloride (PVC). These plastics help factories make items that are strong, bendy, or resist chemicals.

Material | Key Properties | Typical Applications |

High-Density Polyethylene (HDPE) | Strong, lightweight, chemical resistant, easy to recycle | Bottles, industrial containers, automotive parts, outdoor products |

Low-Density Polyethylene (LDPE & LLDPE) | Flexible, durable, resists cracking, stretchy | Squeeze bottles, flexible tubing, plastic films, marine goods |

Polypropylene (PP) | Stiff, heat resistant, chemical resistant | Hot-fill containers, automotive parts, microwave-safe containers |

Polyvinyl Chloride (PVC) | Rigid or flexible, flame resistant, good barrier properties | Flexible bottles, window profiles, pipes |

These plastics let factories make things like pipes, sheets, and films. Factories pick the best material for each product.

Industry Applications

Plastic extrusion is used in many industries. Companies use it to make things for packaging, building, travel, and homes. The table below shows how different industries use plastic extrusion products:

Industry | Main Applications |

Packaging | Bottles, containers, films, trays, and sheets for food, chemicals, and cosmetics |

Construction | Pipes, window and door frames, wall panels, roofing, and drainage systems |

Transportation | Automotive air ducts, road safety barriers, pallets, and marine components |

Medical | Tubing, catheters, and packaging for medical devices |

Consumer Goods | Toys, kitchenware, gardening tools, and home appliances |

Agriculture | Irrigation pipes, greenhouse panels, and fencing |

Plastic extrusion helps industries meet rules for safety and strength. SINOTECH Machinery gives solutions for every industry. They help companies make products that work well.

Manufacturers use plastic extrusion to make custom shapes and sizes. This process helps new ideas in packaging, building, and travel. The many uses of plastic extrusion show why it is important today.

Advantages and Limitations

Benefits in Manufacturing

Plastic extrusion lines give many benefits to factories. They help factories work fast and make lots of products. The machines run all the time, so there is less stopping. This means workers can make more things in less time. Automation and quick mold changes keep the work moving. Workers can change what they make without waiting long. This helps factories stay efficient.

Plastic extrusion lines are flexible. They can use many plastics like PE, PVC, and PP. Factories can make different shapes and sizes for customers. The process can use co-extrusion. This means more than one material can be in a product. It gives extra features to the products.

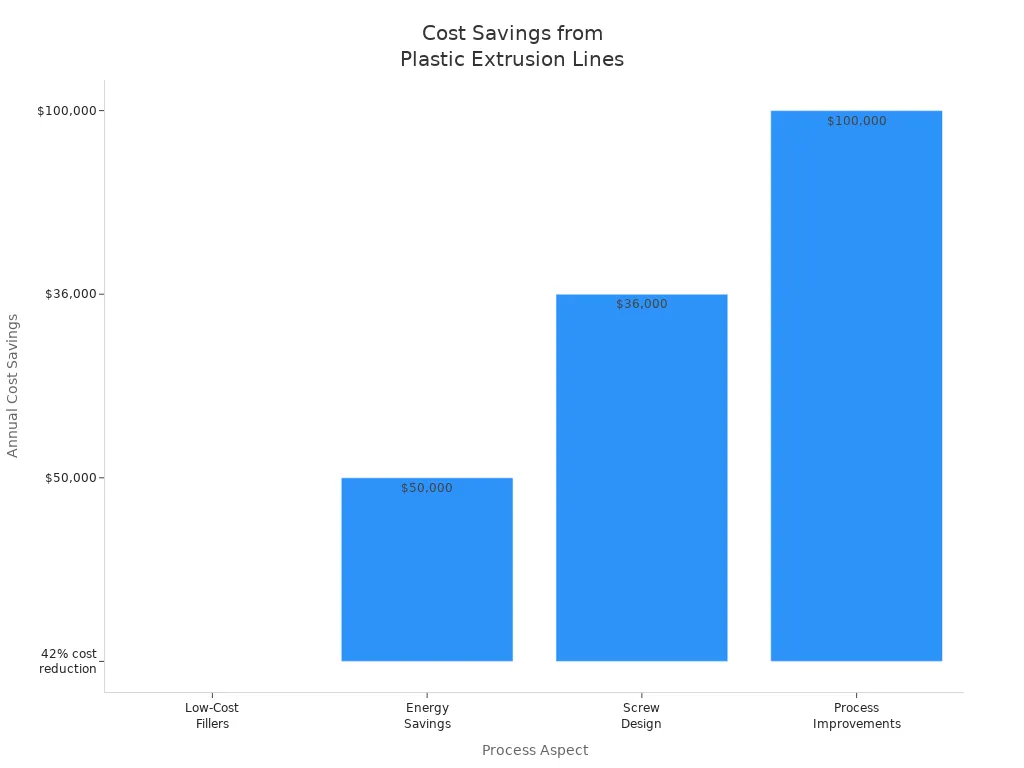

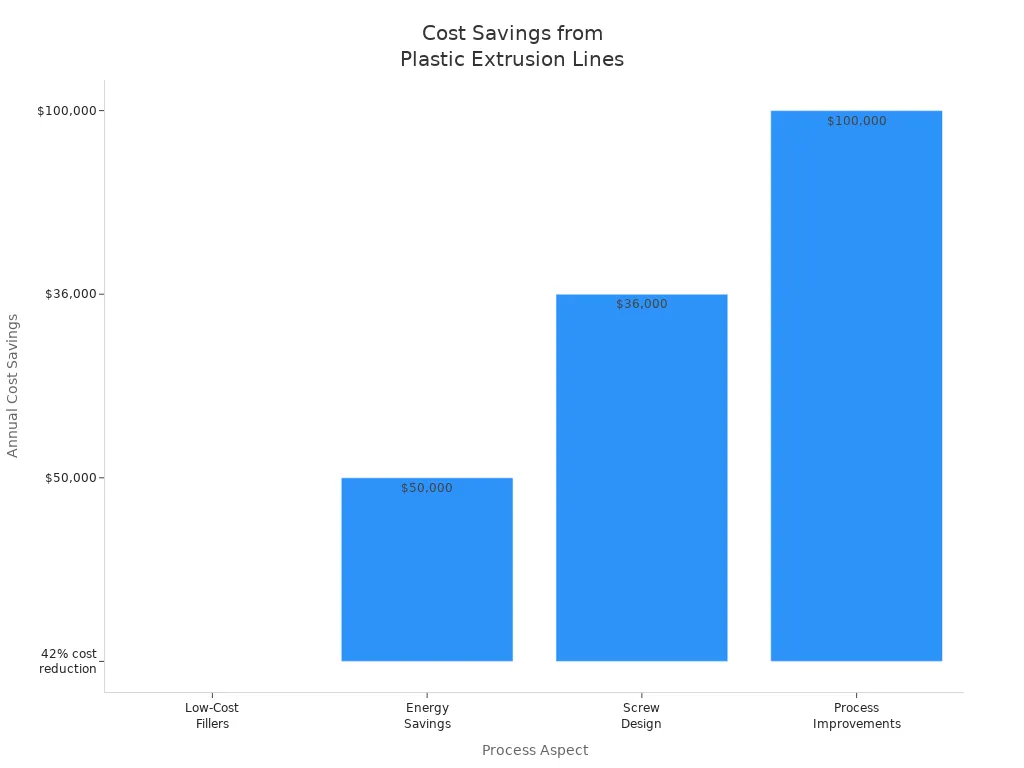

Saving money is another big benefit. Extrusion molds cost less than other molds. The machines use less energy and make less waste. Factories can use fillers and recycled plastic to save even more. New machines use AI controls and modular parts. This helps lower downtime and labor costs.

Plastic extrusion lines help factories make good, standard products. Better machines help products meet size rules and make more items. Energy-saving parts help factories spend less money.

Advantages of plastic extrusion also help the environment. Factories can use recycled plastic and still work well. Real-time checks stop mistakes and keep products the same.

Challenges and Comparisons

Plastic extrusion lines have some problems in factories. Sometimes, product sizes change because of heat, material, or machine wear. These problems can hurt quality and make more waste. Good temperature control and regular checks help keep things working well.

There are limits to design. Plastic extrusion makes shapes that are the same all the way through. If a shape is tricky, it needs more steps. This takes more time and money. Starting a new line costs a lot. Small businesses may find it hard to pay for this, especially if they do not make many products.

When you compare extrusion to injection molding, you see differences. Plastic extrusion is best for making long, even shapes like pipes and sheets. It uses steady energy and cheaper tools. This is good for making lots of the same thing. Injection molding is better for small, detailed parts. It works faster but costs more at the start. Factories pick extrusion for saving money and making simple shapes. They use injection molding for fancy, exact parts.

Limitation/Challenge | Explanation | Impact |

Variations in Product Size | Heat and material changes can make products uneven. | Quality problems and more waste. |

Product Design Limitations | Only same cross-sections; tricky shapes need more work. | More time and money for special designs. |

High Initial Setup Cost | Machines and tools cost a lot at first. | Not good for small or few products. |

Plastic extrusion lines are still a top pick for factories. They are fast, flexible, and save money.

Plastic extrusion lines are very important in today’s factories. They change raw plastic into things for packaging, building, and travel. These lines have many good points:

Using recycled and biodegradable plastics helps the planet.

Machines that save energy and use smart controls cut costs and waste.

New systems make sure products are high quality and work for many jobs.

It is important to pick a supplier you can trust. The table below explains what to check:

Factor | Why It Matters |

Proven Experience | Makes sure you get good products |

Technical Support | Fixes problems fast |

After-Sales Service | Keeps machines working well |

SINOTECH Machinery gives strong help, trusted machines, and lots of know-how. Factories can count on them for green, smart, and fast production in many areas.

FAQ

What products can a plastic extrusion line make?

A plastic extrusion line makes pipes, sheets, films, profiles, and cables. These products are used in packaging, construction, transportation, and home decoration. SINOTECH Machinery builds lines for many different uses.

How does a plastic extrusion line work?

The line melts plastic pellets and pushes them through a die. The melted plastic is shaped, cooled, and then cut or coiled. Each step uses special machines to keep the product good.

What materials do plastic extrusion lines use?

Plastic extrusion lines use materials like PE, PP, and PVC. Each material has its own special features. Factories pick the best one for strength, flexibility, or chemical resistance.

Why do manufacturers choose SINOTECH Machinery?

Manufacturers pick SINOTECH Machinery because their lines are reliable. The company gives technical help, new technology, and strong service after buying. Customers get support from planning to making products.

Can plastic extrusion lines use recycled materials?

Yes, many plastic extrusion lines can use recycled plastics. This helps cut down on waste and supports the environment. SINOTECH Machinery has ways to use recycled materials in production.