A plastic extrusion line helps you make things from raw plastic. You can create pipes, sheets, and profiles with it. You put plastic pellets or powder into the extrusion machine. The machine melts the plastic and pushes it through a shaped die. This makes a long, steady shape. Extrusion gives strong and even results for many industries. You can find plastic extrusion in packaging, construction, and home goods. The plastic extrusion line is fast and flexible. Along with blow molding machines, extrusion technology shapes our daily lives.

A plastic extrusion line heats up raw plastic and shapes it fast. It can make pipes, sheets, or other shapes. The machine does this evenly every time.

The main parts are the extruder, hopper, screw, barrel, die, cooling system, puller, and cutter. These parts all work together as a team.

You can change the speed, temperature, and die shape. This helps make different things for packaging, building, or home use.

Plastic extrusion uses less energy and material. It is flexible and makes strong, good-quality items with less waste.

Keeping the machine clean and picking the right plastic and die is important. This helps stop problems and keeps the work going well.

Plastic Extrusion Line Basics

What Is a Plastic Extrusion Line

You use a plastic extrusion line to turn raw plastic into useful shapes. This system helps you make pipes, sheets, profiles, and more. The plastic extrusion line works by heating plastic and pushing it through a mold called a die. You get long, continuous products with even thickness and strong structure. Many industries rely on plastic extrusion for packaging, construction, and home goods. When you want to produce large volumes of plastic items quickly, you choose a plastic extrusion machine. The core function of the extrusion line is to melt, shape, and cool plastic so you get the exact product you need.

Tip: If you want to make plastic pipes or sheets, a plastic extrusion line gives you speed and flexibility. You can adjust the machine to create different shapes and sizes.

Main Components

You find several important parts in every plastic extrusion machine. Each part plays a key role in the extrusion process. Here are the main components of a plastic extrusion machine:

Component | Function |

Extruder | Heats and pushes plastic through the system |

Hopper | Holds and feeds raw plastic pellets or powder |

Screw | Moves and melts plastic inside the barrel |

Barrel | Contains the screw and heats the plastic |

Die | Shapes the melted plastic into the final product |

Cooling System | Cools the shaped plastic to set its form |

Puller | Pulls the product out of the die at a steady speed |

Cutter | Cuts the product into desired lengths |

Auxiliary Equipment | Supports the process (like mixers, dryers, and sensors) |

You see that each part works together to make the extrusion process smooth and efficient. The extruder is the heart of the plastic extrusion machine. The hopper stores the plastic before it enters the screw and barrel. The screw rotates and pushes the plastic forward while heating it. The barrel keeps the temperature steady. The die gives the plastic its final shape. The cooling system sets the shape. The puller and cutter finish the process by moving and cutting the product. Auxiliary equipment helps you control quality and speed.

How Plastic Extrusion Machines Work

You start the process by loading plastic pellets or powder into the hopper. The extruder uses the screw to move the plastic through the barrel. The barrel heats the plastic until it melts. The melted plastic flows toward the die. The die shapes the plastic into a pipe, sheet, or profile. The cooling system lowers the temperature so the plastic keeps its shape. The puller moves the product forward at a steady rate. The cutter slices the product into the lengths you want.

Here is a simple step-by-step list of how plastic extrusion machines work:

You load raw plastic into the hopper.

The screw rotates and pushes plastic through the barrel.

The barrel heats and melts the plastic.

The melted plastic enters the die.

The die shapes the plastic.

The cooling system sets the shape.

The puller moves the product forward.

The cutter trims the product.

You control each part of the process to get the best results. You can adjust the speed, temperature, and die shape to match your needs. SINOTECH Machinery Co., Ltd. offers advanced plastic extrusion lines with reliable extruders and smart controls. You can also find related machines like blow molding machines and plastic recycling lines for different production needs.

Note: If you want to learn more about how plastic extrusion machines work, you can visit SINOTECH Machinery’s product page for detailed specifications and videos.

Plastic Extrusion Process

The plastic extrusion process turns raw plastic into useful things. Many industries use this process, like packaging and construction. You follow steps to change plastic pellets or powder into a finished product. Let’s look at each stage of making plastic items.

Feeding and Melting

First, you put raw material into the hopper of the plastic extrusion machine. The hopper holds the plastic and drops it into the extruder. The extruder has a screw that spins and moves the plastic forward. As the screw turns, it pushes the plastic through the barrel. The barrel gets hot and melts the plastic. You set the temperature to melt the plastic evenly. This step matters because good melting makes strong and nice-looking products.

Tip: Always check your machine’s temperature settings. Good melting helps the process go smoothly and cuts down on waste.

The melted plastic turns thick and sticky. Now it is ready for the next step. You can use different plastics, like PE, PP, or PVC, for your needs. SINOTECH Machinery Co., Ltd. makes machines that work with many plastics. This helps you make many kinds of products.

Extruding Through the Die

After melting, the plastic moves to the die. The die is a tool that shapes the melted plastic. You pick a die for the shape you want, like a pipe or sheet. Pushing plastic through the die is the most important step. The die gives the plastic its final shape and size. You get a long, steady product called extrudate.

You can change the speed and pressure to control thickness and width. The machine helps you make products with exact sizes. If you want special shapes, you can use a different die. This makes plastic extrusion a good choice for making many things.

Note: The die’s quality affects your product’s quality. SINOTECH Machinery Co., Ltd. has advanced dies for many uses, so you get great results.

Cooling and Cutting

When the plastic leaves the die, it is still hot and soft. You must cool the extrudate fast to keep its shape. The cooling system uses water or air to cool it down. Cooling is important because it makes the product strong and keeps its shape. Every plastic extrusion line uses this step.

After cooling, the puller moves the product forward at a steady speed. The cutter slices the product into the lengths you want. Now you have a finished product, ready to use or process more. The plastic extrusion process gives you smooth and even products.

You can use the machine to make pipes, sheets, and profiles for many industries. If you want to recycle plastic waste, you can add a recycling line. For hollow items, you might use a blow molding machine. SINOTECH Machinery Co., Ltd. gives you all the machines you need for plastic production.

Call to Action: If you want to make your production better or learn more, contact SINOTECH Machinery Co., Ltd. Their experts can help you pick the right machine and support your work.

Types and Applications

Types of Plastic Extrusion

There are different kinds of plastic extrusion machines. Each one helps you make a certain product. Here are the main types you can use:

Single Screw Extrusion: This type is good for simple shapes. It works for pipes, sheets, and profiles.

Twin Screw Extrusion: You use this when you want to mix things or add color. It lets you control the process better.

Profile Extrusion: This machine makes window frames, door profiles, and special shapes.

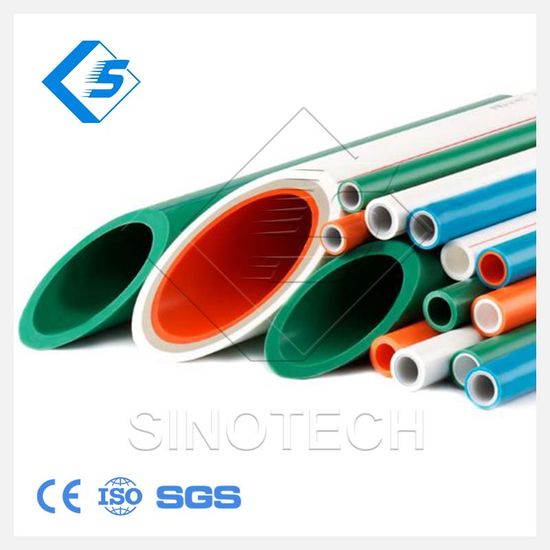

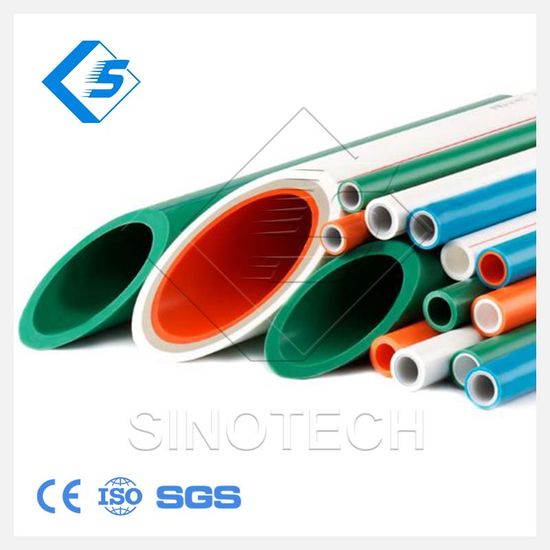

Pipe Extrusion: You use this to make pipes for water, gas, or drains.

Sheet Extrusion: This type makes flat sheets for packaging and building.

Specialty Extrusion: You use this for tubing, blow film, and other special products.

Tip: If you want to make hollow things or recycle plastic, you can use blow molding machines and plastic recycling lines from SINOTECH Machinery Co., Ltd.

Materials Used

You can use many plastics in the extrusion process. Each plastic gives your product different features. Here is a table that shows common plastics and what they are used for:

Plastic Type | Common Uses |

PE | Pipes, sheets, packaging |

PP | Profiles, automotive parts |

PVC | Construction, window frames, pipes |

PETG | Bottles, sheets, cosmetic packaging |

PLA | Eco-friendly packaging |

You pick the right plastic for your job. SINOTECH Machinery Co., Ltd. makes machines that work with many plastics. This helps you make strong and useful products.

Industry Applications

Plastic extrusion is used in many industries. The process helps make things for homes and businesses. Here are some ways plastic extrusion is used:

Packaging Industry: You make bottles, containers, and films for food and drinks.

Construction Material: You make pipes, wall panels, and window profiles.

Transportation: You make car ducts, pallets, and road safety items.

Home Goods: You make panels, fake marble sheets, and furniture profiles.

Advertisement: You use extrusion for banners and display signs.

Note: SINOTECH Machinery Co., Ltd. gives you advanced extrusion lines for all these jobs. You get help and custom solutions for your needs.

If you want to make better plastic products or try new markets, contact SINOTECH Machinery Co., Ltd. Their experts help you pick the best extrusion machine for your business.

Advantages and Limitations

Key Benefits

A plastic extrusion line has many good points. It lets you make lots of plastic items fast. You can create many products in a short time. The process gives you steady and high-quality results. You can use it to make pipes, sheets, and profiles for many uses. It works well for packaging, building, and home goods.

Plastic extrusion lines are flexible. You can switch the die to change shapes and sizes. This means one machine can make many things for different customers. The process saves money because it uses less energy and raw plastic. You also waste less material. SINOTECH Machinery Co., Ltd. gives strong technical help. They help you set up, train, and fix your machine. This support keeps your line working well.

Tip: If you want to grow your business, you can add blow molding machines or plastic recycling lines. These machines work with your extrusion line and help you make more products.

Main Challenges

There are some problems you might face with plastic extrusion. Not all plastics work with every process. You must pick the right plastic for your product. Some shapes are hard to make with extrusion. If you want complex designs, you may need special dies or extra steps.

You need to keep your machine in good condition. Doing regular checks helps stop problems and keeps things running. If you skip maintenance, your products might have defects. You also need to watch the temperature and speed. Good control gives you better products.

Note: SINOTECH Machinery Co., Ltd. gives expert help and advice. You can ask their team if you have questions or want to make your process better.

You have learned how a plastic extrusion line works. This process changes raw plastic into pipes, sheets, and profiles. Many industries use these products. Extrusion helps you make strong and reliable things. You can use it for many different needs. Companies use extrusion for packaging, building, and home items. If you want to make more products, you can add a blow molding machine or a plastic recycling line. For help, you can talk to SINOTECH Machinery Co., Ltd. Their team will help you pick the best extrusion solution.

Want to grow your business? Contact SINOTECH Machinery Co., Ltd. for help and custom plastic extrusion solutions.

FAQ

What products can you make with a plastic extrusion line?

You can make pipes, sheets, profiles, and films. Many industries use these for packaging, building, and home items. If you want special shapes, you can change the die.

How do you choose the right plastic extrusion machine?

Think about what product you want to make. Pick the material and how much you need to produce. SINOTECH Machinery Co., Ltd. gives advice and has many machines. They offer blow molding machines and recycling lines for your needs.

What materials work best in plastic extrusion?

You can use PE, PP, PVC, PETG, and PLA. Each one has different features. PE is good for pipes. PVC works well for construction profiles. Always pick the material that fits your product.

How do you maintain a plastic extrusion line?

Clean and check your machine often to keep it working well. Look at the screw, barrel, and die for damage. SINOTECH Machinery Co., Ltd. gives help and training for maintenance.

Where can you get technical support for your extrusion line?

You can reach out to SINOTECH Machinery Co., Ltd. for help and training. Their team fixes problems fast and keeps your production running smoothly.