Barrel Tire Double Shaft Shredder Machine

1. PLC control

2. Multiple switch protected

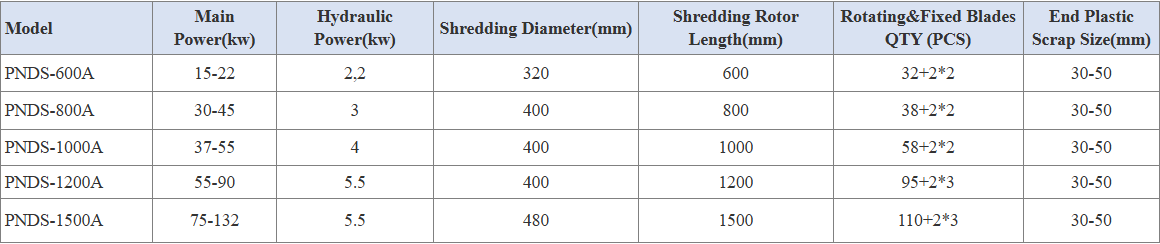

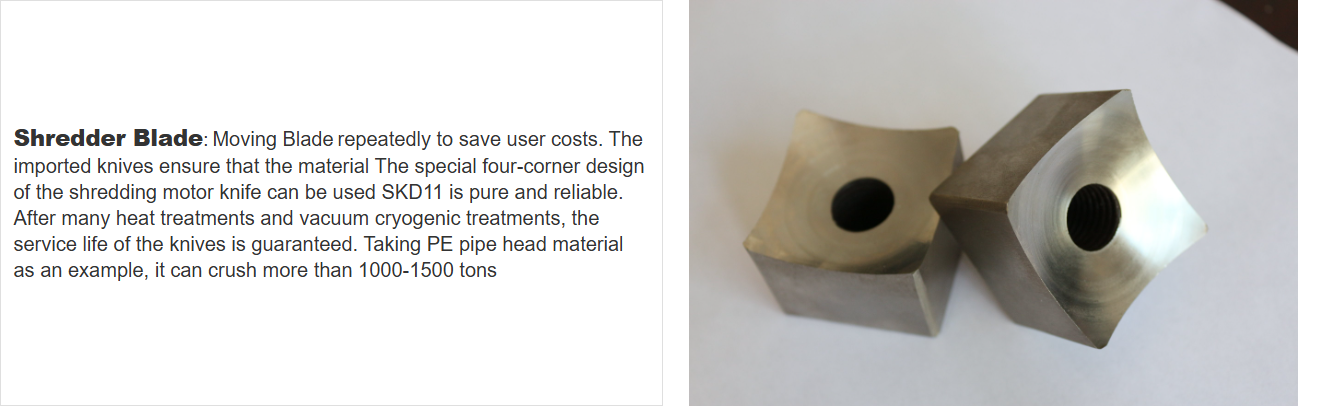

3. Blade material Cr12MOV

Features

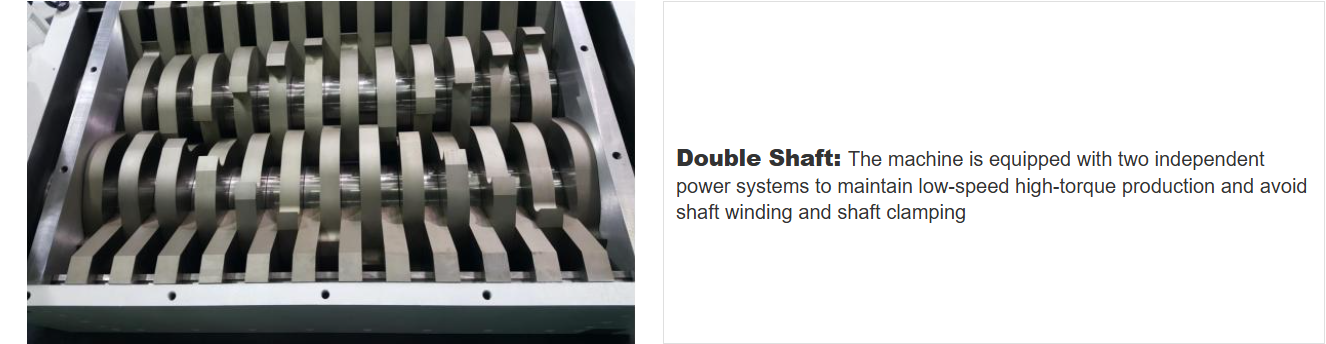

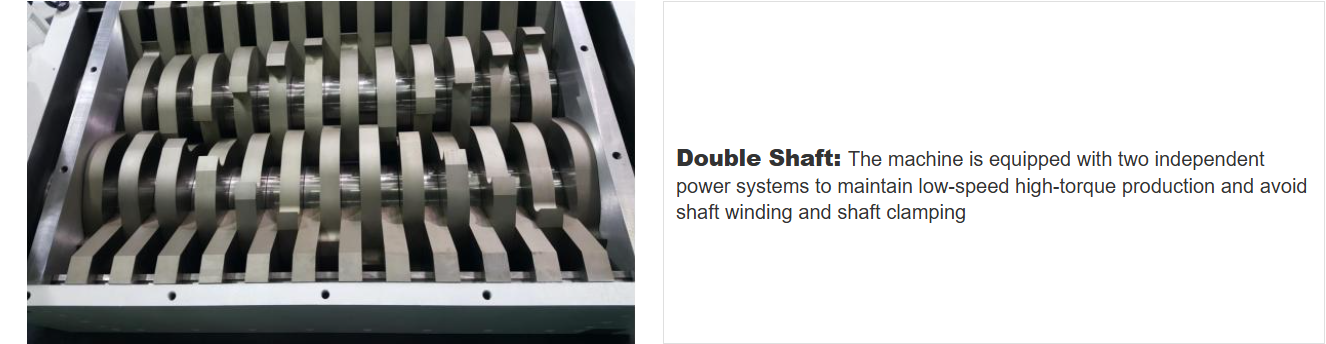

· This series of biaxial shredding machine with double motors, double speed reducer design, ensure that the two main shaft of the machine cavity get equilibrium torque drivers.

· Adopts hardfaced cylindrical gear reducer drive, power strong.

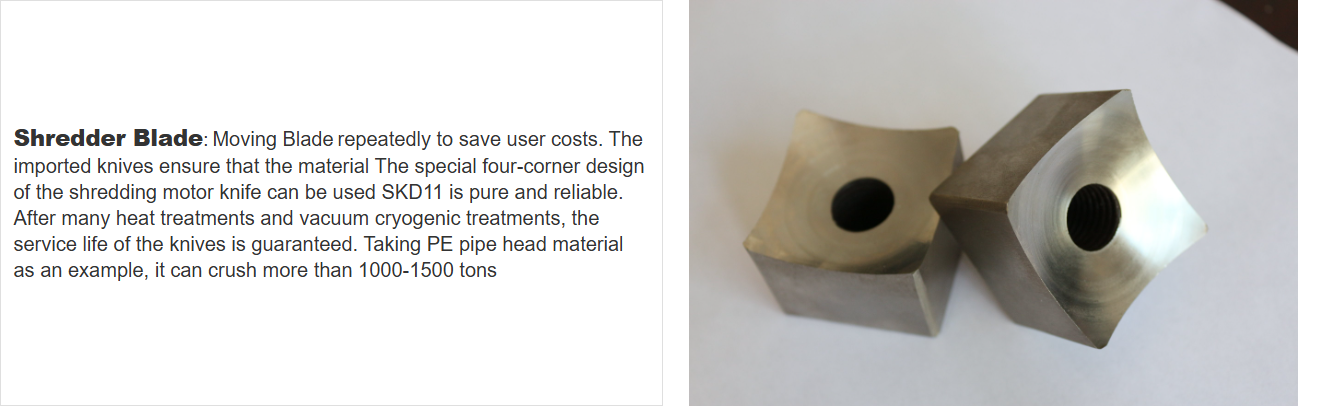

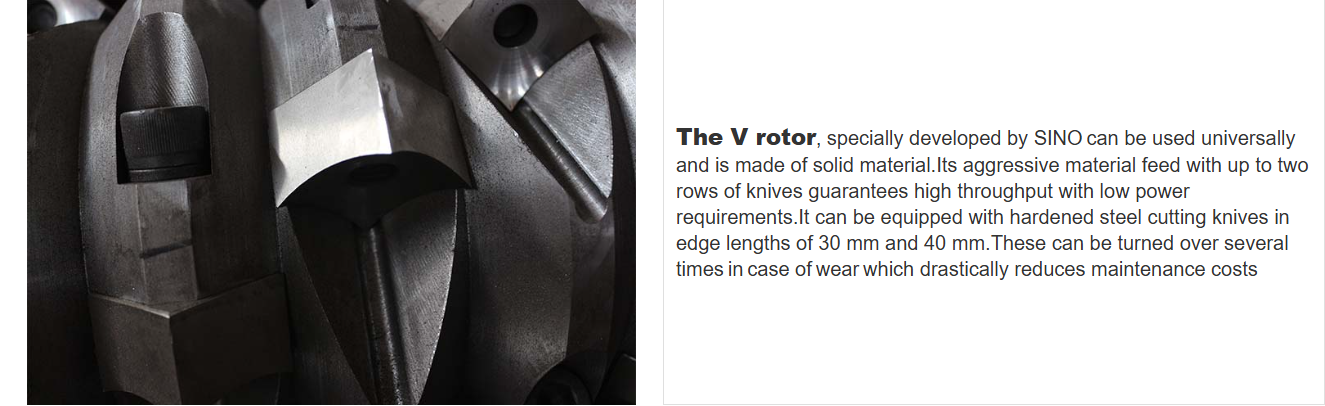

· Blade using special special alloy tool steel forging and heat treatment several times, have very strong abrasion resistance and high strength, and have ability to repair use many times.

· This series shredding machine have torn, extrusion, occlusion, and other functions.

· Set to start, stop, reverse and overload automatic inversion of control function, effective protection and the main part of the machine tool.

· With a low speed, high torque and low noise characteristics.

Important note

1. The thickness of the shredding machine knife is divided into 15 mm, 20 mm, 40 mm, 50 mm and 75 mm, 100 mm, can choose according to object particle size after being broken blade.

2. The shredding machine knives for single claw blade, if you need more than double claw blade and claw blade users can contact the sales department.

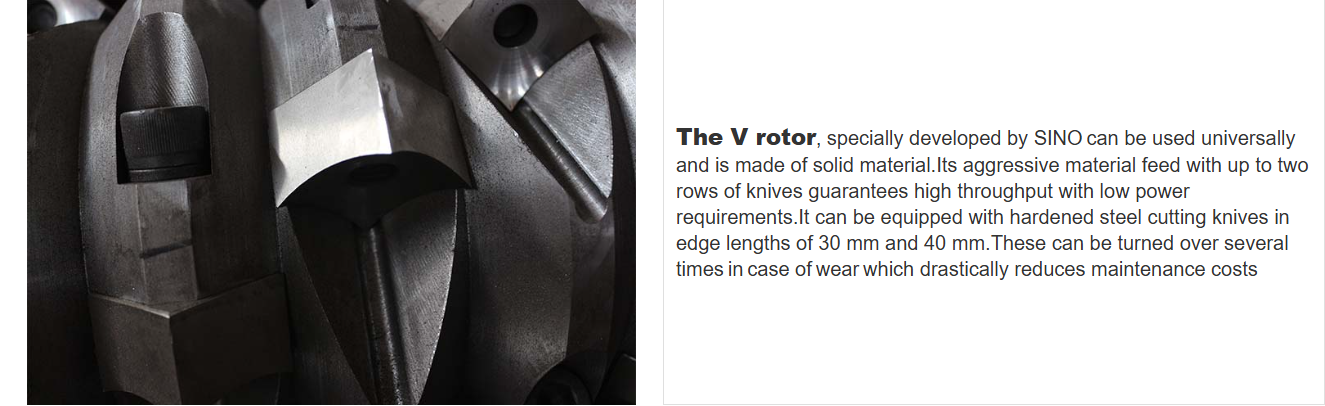

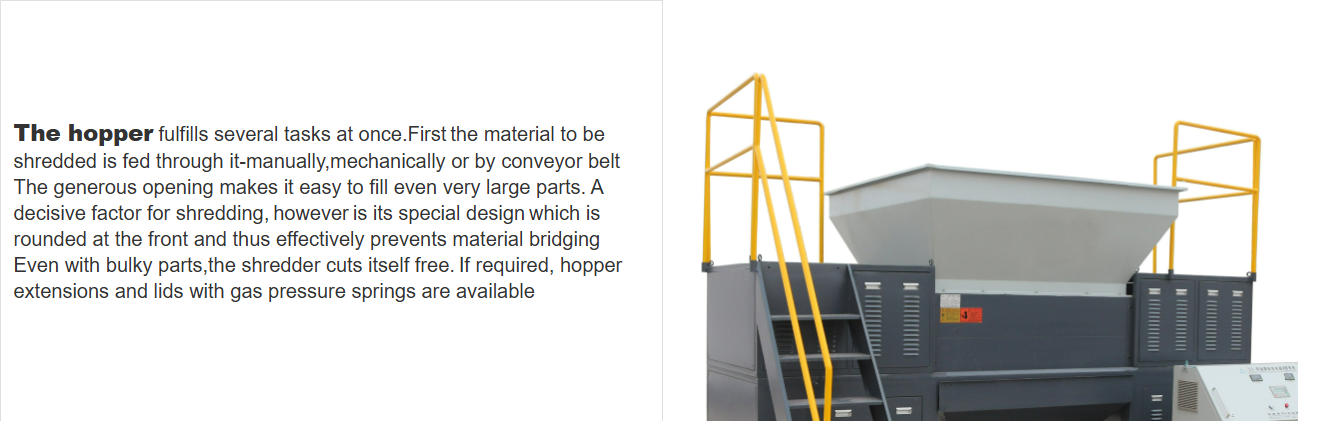

3. The multifunctional shredding machine for grinding chunks of material, basket, tubes, plates, wood, tires, scrap metal barrel, big roll of film can be broken;Thick plate precision machining of composite frame structure, large Angle of six strong axis of rotation Angle, large diameter solid into the hopper, so you can rest assured put into large raw material.

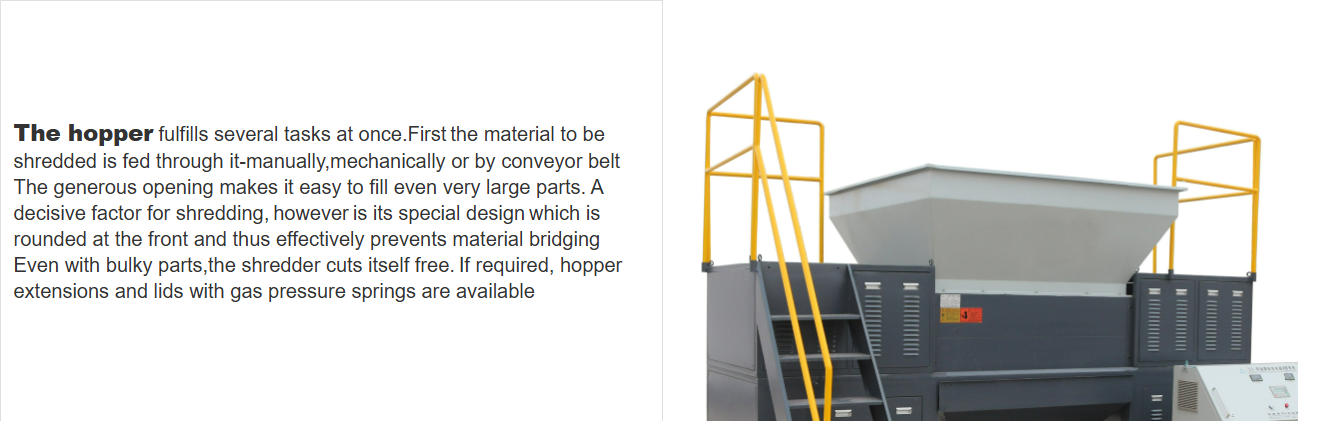

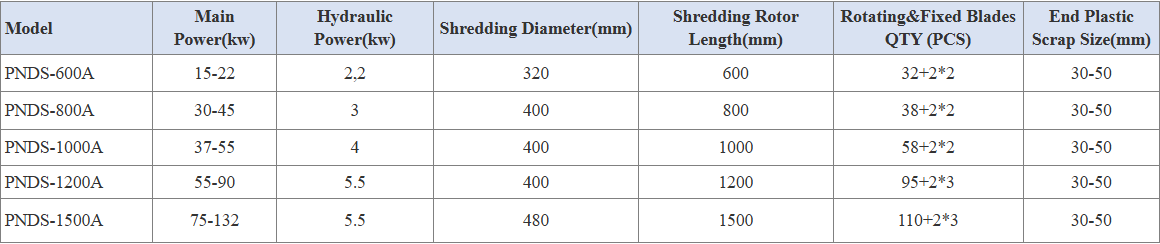

Product Parameters

Application

The double-shaft plastic shredder uses two sets of rotors with shredder blades to rotate relative to each other in the machine cutting chamber of the equipment, so as to squeeze the material entering the machine cutting chamber by the principle of shrinking the angle between the two shafts.The material after the angle of the shaft is fixed by the edge of the blade to further create conditions for the shrinkage of the angle. After the material reaches the yield strength of the material, the material begins to break between the blades, thereby completing the shredding effect.

Application of double shaft shredder:

1.all kinds of hollow container: plastic cans, plastic buckets, iron drum, packing boxes, packaging barrels

2.of waste household appliances, TV sets, washing machine, refrigerator shell industrial shredder

3.tubes, large pipes, pipe fittings, PE pipes

4.used templates: wooden pallets, plastic pallet, forklift plate wood pallet shredder

5.tyre shredder machine can shredding old tires, car tires, truck tires waste tire shredder

6.scrap metal, motor shell, aluminum alloy, scrap aluminum parts, motor shell, lead, and the steel plate thickness under 5 mm metal shredder

7.eat hutch waste, living garbage, dead animals, RDF derivatives, medical waste, straw, garden rubbish

8.plastic head, mill twisted rope.

Key features of waste material shredder:

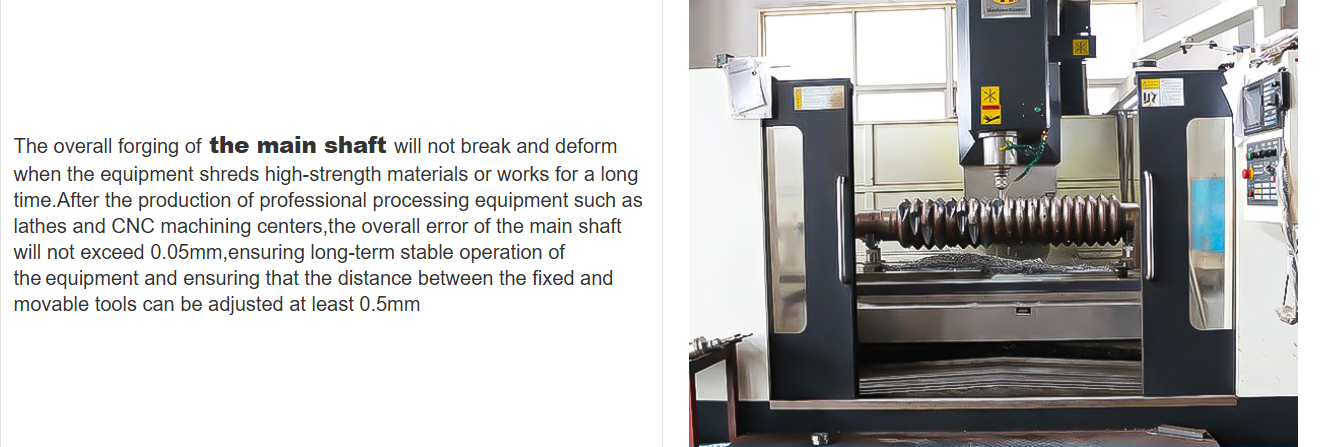

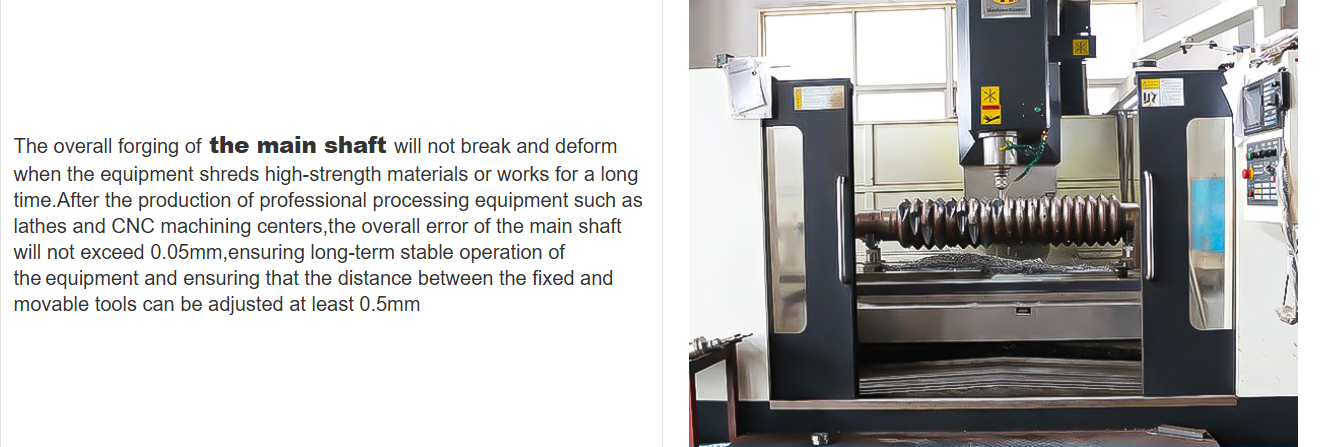

(1) Shredding room adopts large thickness, high stength, wear resistance of steel. The whole crushing room was finished by CNC machine, with high precision, easy disassembly, repair, maintenance, long life and other advantages;

(2) The shredderknives use imported high-quality alloy steel, with high strength, good toughness, not easy to break and so on. And to ensure that there is a good blade in the work, disassembly, and easy to maintenance;

(3) Shraft adopts a special material processed by CNC machine, with high stength, good toughness, stable work status and not easy to out of shape, stable work status.

(4) Rotary blades can use integral blades or assemble blades, blades structure can be divided into single claw blades, double claw blades and dual-claw blades. Rotary blades can cut material evenly, reduce energy consumption, reduce noise, loading and unloading blades is very conveinent.

(5) Screen using high-strength material processing, high strength, long service life, and easy to operate.

Q: Can we visit your factory?

Sure. We located in Zhangjiagang city which is very near Shanghai. For overseas customers, you can fly to Shanghai Pudong International Airport. We can pick you up in the Airport. (or Hongqiao International Airport. ) We also provide visit online by video.

Q: How can we get the exact price of plastic machine?

Contact us with the products size, shape, annual quantity and photo if possible. We can recommend our machine models with quotation.

Q: Do you provide any spare parts with machine?

Yes, we offer all necessary spare parts before shipment.(contact us for packing list )

Q: How about your after-sale service ?

We offer manual instruction and engineer training before loading,after shipment we provide 24 HRS online support, video technical support or field installation assist.

Q: What is the lead time?

For customized machine, it takes about 45-60 days after deposit. For stock machine, fast shipment. ( The actual production cycle will vary according to the degree of customization.)

Q: What is the warranty period for your machine ?

12 months warranty for components and technical support .

Q: Do you provide custom machines?

Most of our machines are customized. Our goal is efficiency and stable performance. We design the machines according to customers products to meet customer' needs.

Q: How can we install the machine when it arrives?

We can send experienced technicians to customer's country for guiding the installation and commission the machine, also train the customer's employees.

Q: What's the advantage of SINOTECH?

We provide customers with turnkey projects. Including plant design, plastic machine and mold installation, debugging, also we can source the auxiliary equipments for customers. We can ship the full set of machines after testing in our factory. It will save a lot of cost and time.