100ml-2L Plastic bottle extrusion blow molding machine

Product Introduction

The 100ml-2L Plastic Bottle Extrusion Blow Molding Machine is designed to meet the increasing demand for small to medium-sized plastic bottles used across various industries, including cosmetics, pharmaceuticals, chemicals, and food packaging. Capable of producing bottles ranging from 100ml to 2L, this machine uses advanced extrusion blow molding technology, offering high precision, rapid cycle times, and outstanding production efficiency.

Equipped with multi-cavity capabilities and the option for up to four layers, it offers customized production to ensure uniform, high-quality bottles with minimal material waste. This machine is ideal for companies looking for a flexible and cost-effective solution to produce HDPE, LDPE, PP, PVC, and EVA bottles.

Product Features

Versatile Bottle Production

This machine is capable of producing a wide variety of plastic bottles ranging from 100ml to 2L. Whether it’s for cosmetic containers, pharmaceutical bottles, or food packaging, the machine caters to a diverse range of industries, ensuring high-quality output for all applications.

Multi-Cavity Mold Options

The multi-cavity design allows businesses to produce multiple bottles in one cycle, significantly increasing production speed without sacrificing consistency. Options include single, double, triple, and quadruple cavities, providing flexibility for varying production volumes.

Layered Extrusion Capabilities

Featuring a 1 to 3 layer extrusion system, this machine allows for the production of bottles with enhanced durability or special barrier properties. Customizable layers provide increased strength and protection, meeting the specific requirements for products like pharmaceutical containers and chemical bottles.

Product Advantages

High-Speed Production Efficiency

The machine is equipped with a dual-station system, allowing for faster cycle times and increased output. This setup makes it a perfect solution for businesses looking to streamline production and reduce downtime, especially when producing small to medium-sized bottles in high volumes.

Energy-Saving Performance

Thanks to servo-driven motors and an auto lubrication system, the machine operates with reduced energy consumption. This energy-efficient design not only lowers operating costs but also ensures consistent performance throughout extended production runs.

Advanced Control and Monitoring

The Mitsubishi PLC control system, coupled with an intuitive human-machine interface, offers seamless operation. Operators can monitor key parameters in real-time, enhancing ease of use and boosting production efficiency. This system ensures reliable, precise control over the molding process.

Product Parameters

| Parameter | Value |

| Screw Diameter | φ50mm |

| Screw L/D Ratio | 25:1 |

| Plasticizing Capacity | 70 KG/Hr |

| Clamping Force | 60 KN |

| Max. Product Volume | 2L |

| Platen Dimension | 370×390 mm |

| Max. Working Pressure | 140 kg/cm² |

| Blowing Pin Stroke | Adjustable |

| Heating Power | 3φ7.5KW |

| Overall Dimensions | 3430×2320×2650mm |

| Machine Weight | 7.0 tons |

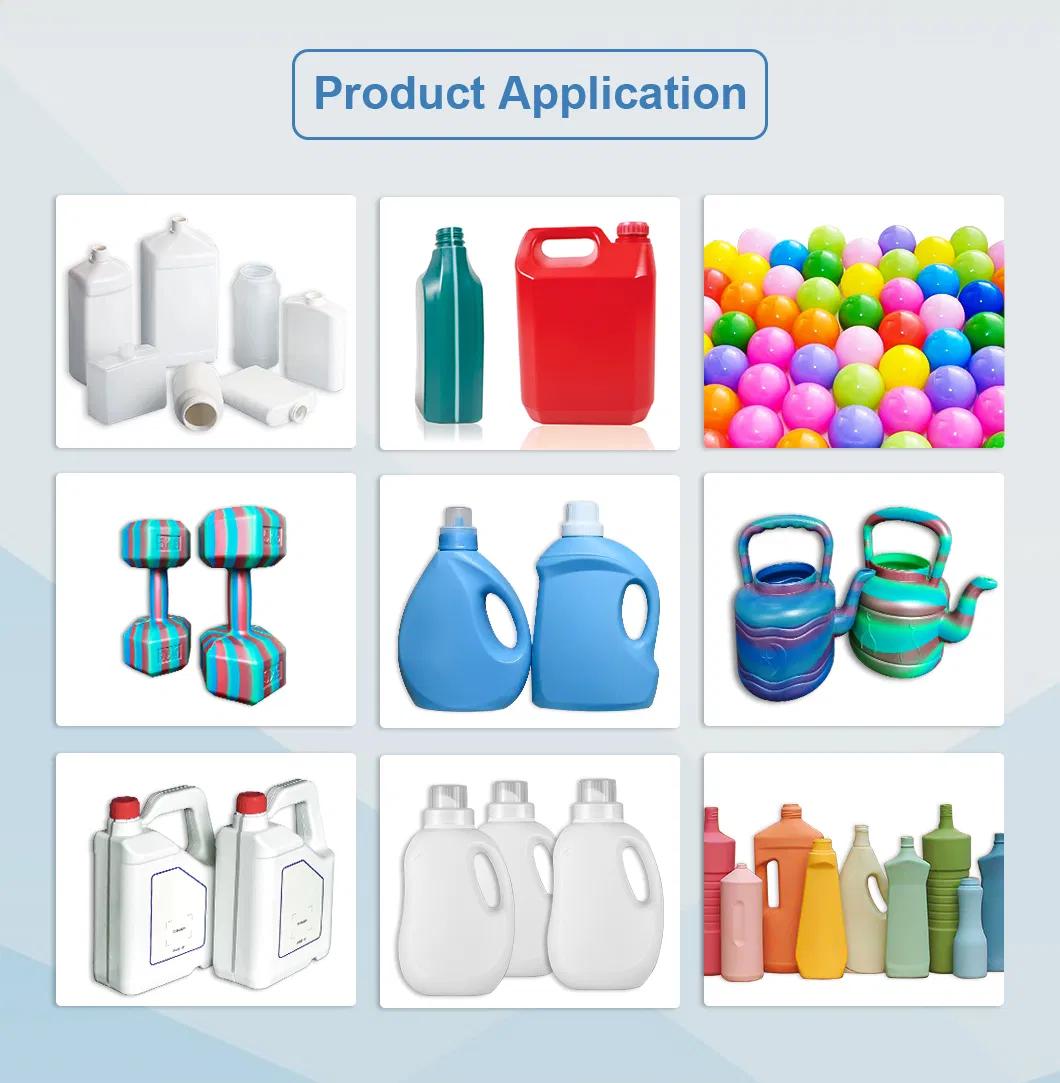

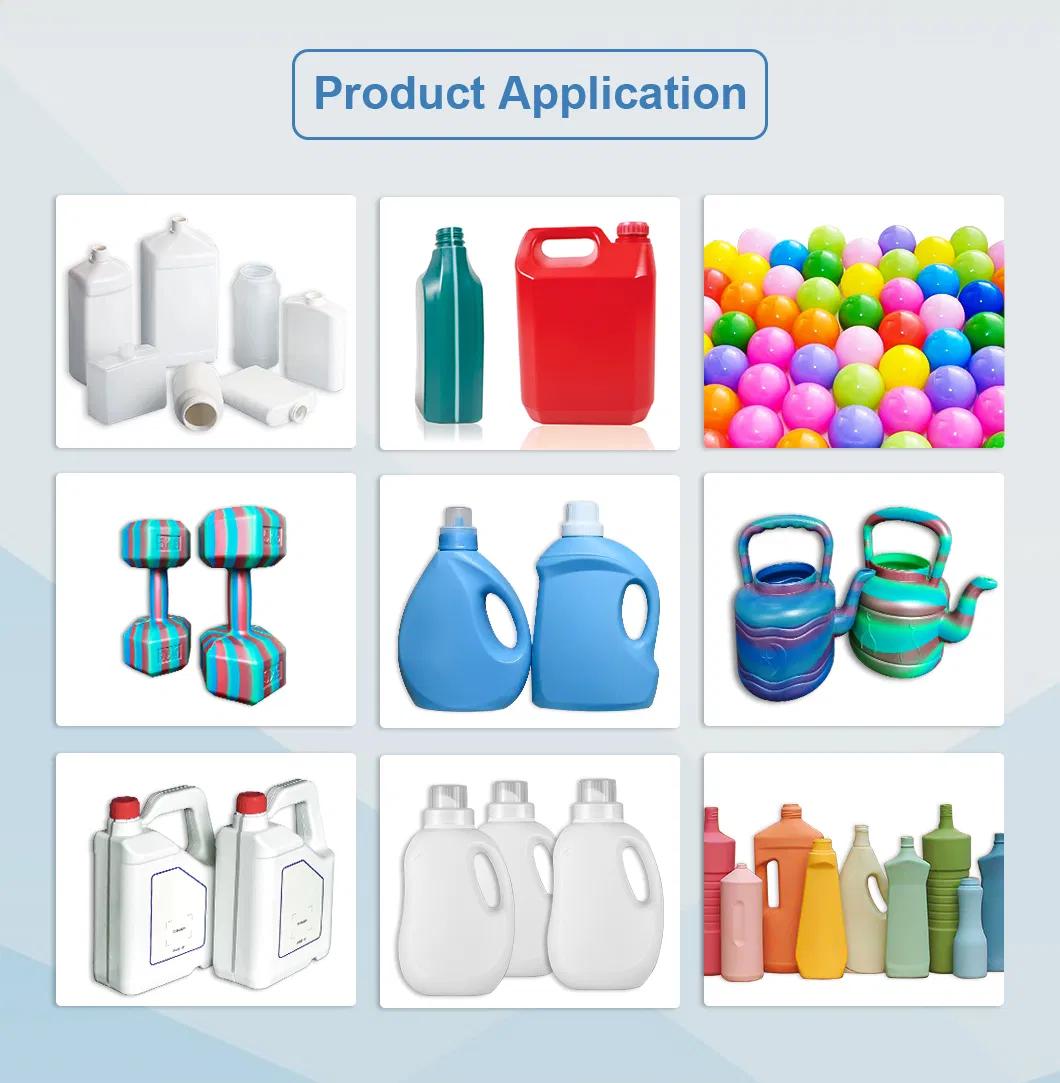

Product Application

The 100ml-2L Plastic Bottle Extrusion Blow Molding Machine is designed for the production of various plastic bottles, including:

Cosmetic Bottles: Ideal for producing small cosmetic containers such as lotions, shampoos, and creams.

Pharmaceutical Bottles: Perfect for medicine bottles requiring precise control of material properties and volume.

Food Packaging: Used in the production of milk bottles and other beverage containers.

Chemical Bottles: Capable of manufacturing bottles used in household cleaners, detergents, and other chemical products.

Why Choose Us?

At SINOTECH Machinery Co., Ltd., we specialize in designing and manufacturing high-performance extrusion blow molding machines that offer cost-effective solutions for plastic bottle production. With over 20 years of industry experience, we pride ourselves on providing precision, reliability, and energy-efficient solutions. Our machines are built to help businesses reduce operational costs while increasing productivity, making them the ideal choice for companies aiming to optimize manufacturing processes.

| uint | item | specification | discription | note |

Extruding | Screw diameter | φ60mm | Mixing model |

|

| Screw L/D | 25:1 |

|

|

| Material of screw and barrel |

| 38CrMoALA |

|

| Plasticizing capacity | 60KG/Hr | Based on HDPE5502, changed with different material density |

|

| Extruding method |

| Inverter motor, hardness tooth surface gear box |

|

| Driving power | 15KW |

|

|

| Screw revolution | 10—100rpm |

|

|

| Heating zones | 3 | Temperature module, Mitsubishi |

|

| Heating power | 3φ4.7KW |

|

|

| blowers | 3 | Power 120W |

|

| cooling | yes | Cooling water for feeding zone and gear box |

|

| Clamping unit | Structure

|

| Large arm and joint operation type, with large and average clamping force |

|

| Idle cycle time | 900×2 pc/h |

|

|

| Platen dimension | 286×320 mm | W×H |

|

| Platen distance | 138~368mm |

|

|

| Clamping force | 40KN |

|

|

| Mold thickness scope | 138~180 mm |

|

|

| stroke | 320mm |

|

|

| Die head | structure | continuous | Central feeding |

|

| Center distance | 60mm | Quadruple head |

|

| Material |

| 38CrMoALA inner mirror |

|

| Die mouth | Φ10~Φ55 mm |

|

|

| Heating method |

| Stainless steel band |

|

| Heating zones | 4 |

|

|

| Die head blowing | Yes |

|

|

| Parison thickness controlling | available | MOOG 100-point |

|

| Parison adjustment method | Outer mandral |

|

|

| Adjustment | ±2 mm |

|

|

Up blowing

unit |

|

| Equip with a set of double head & double blowing |

|

| Controlling system | Temperature | Module | Mitsubishi |

|

| Programmer | Mitsubishi |

|

|

| Human interface screen | HITECH | Taiwan |

|

| hydraulic | Oil motor power | 5.5KW |

|

|

| Brand | HYTEK | Taiwan |

|

| Controlling | proportional |

|

|

| Max. working pressure | 140 kg/cm2 |

|

|

| Pneumatics | maker | AIRTEC | Taiwan |

|

| Pressure controlling |

| Separate two adjusters for high and low pressure |

|

| Max. pressure | 8kg/cm,1.0m3/min |

|

|

Other information

| Lubricative method |

| Auto lubricate oil pump |

|

| Overall dimension | L*W*H | 3200*2120*2550mm |

|

| weight | TON | 6.0T |

|