1000 Kg/h PET Bottle Washing Recycling Line

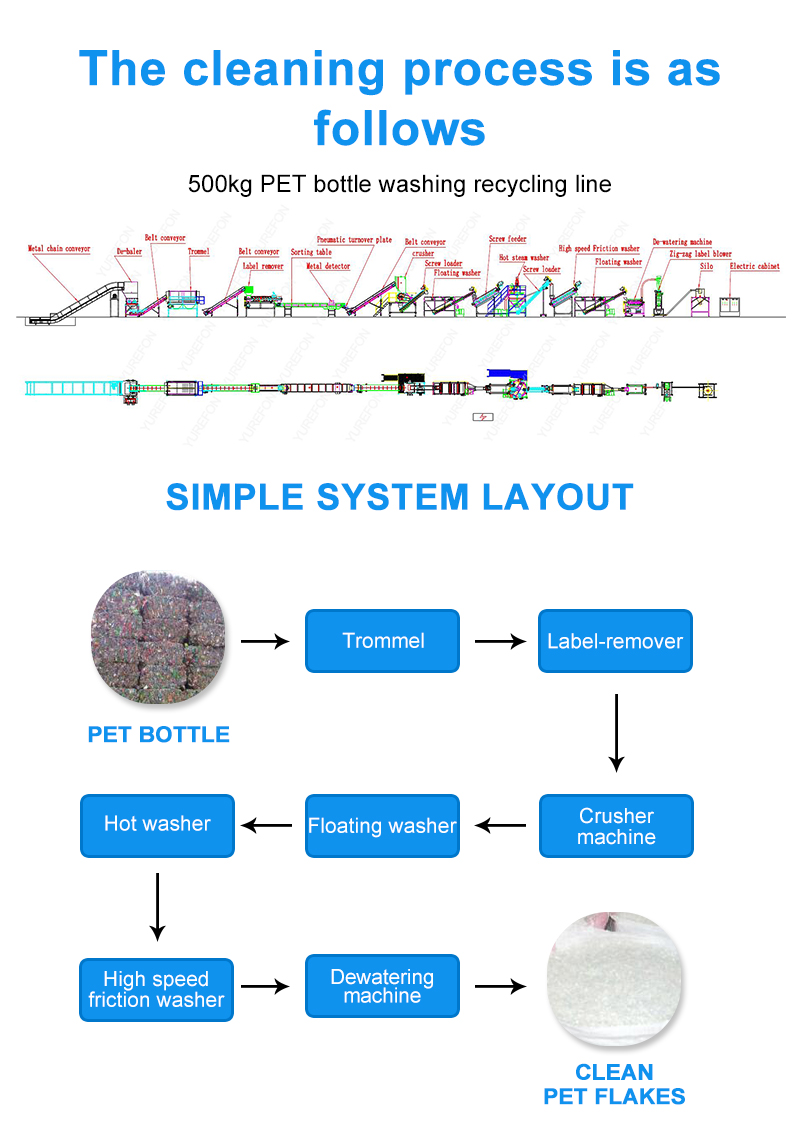

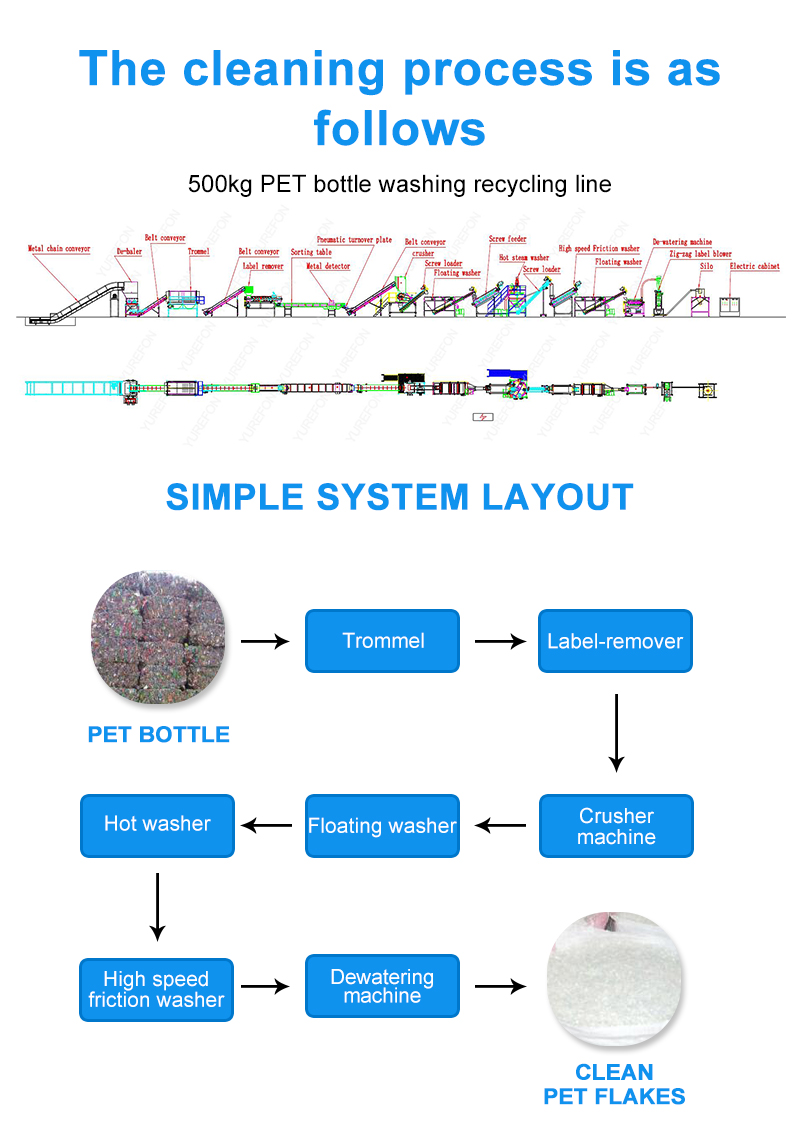

PET bottle washing recycling line is a full automatic crushing washing dewatering and drying production line, it is the ideal equipment to waste mineral water bottles, cola bottle, PET bottle sorting, label removing, crushing, washing, dewatering and drying machines.

Product Description:

This line is mainly used for recycling the waste PET bottle, PET container etc.

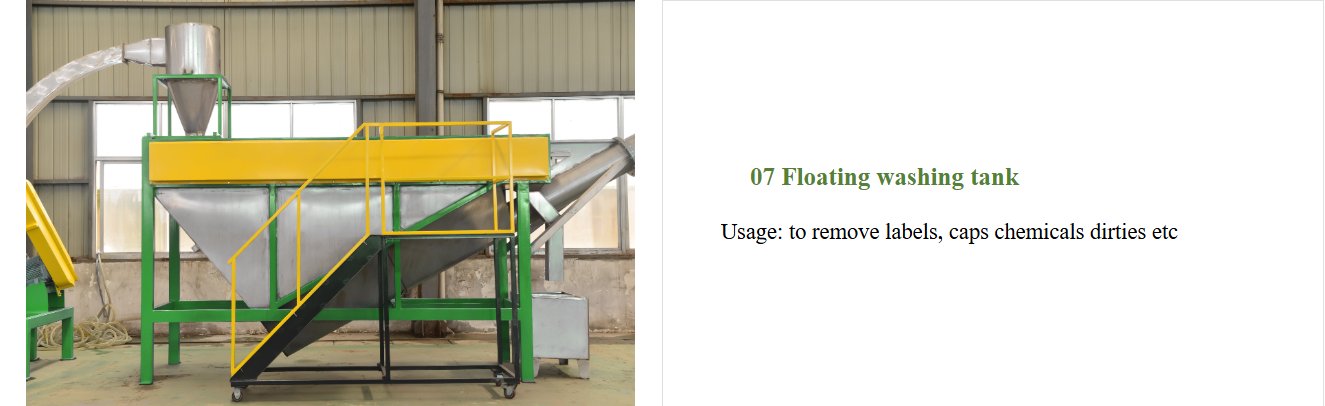

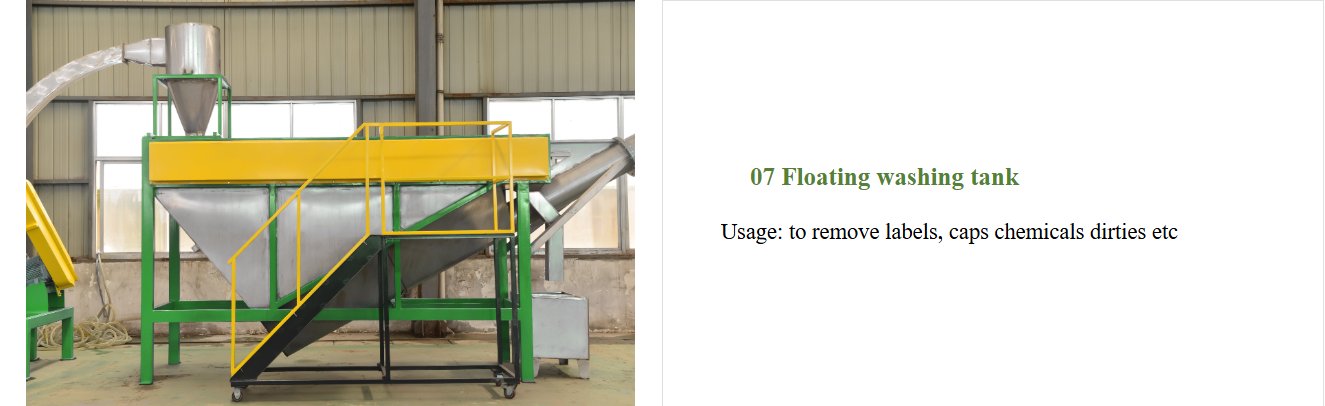

2. To separate PET bottles to flakes from label, cap, oil, garbage.

3. This line is composed of separator, crusher, cold & hot washing system, dewatering, drying, packing system, etc.

4. Easy to operate, Full automatic.

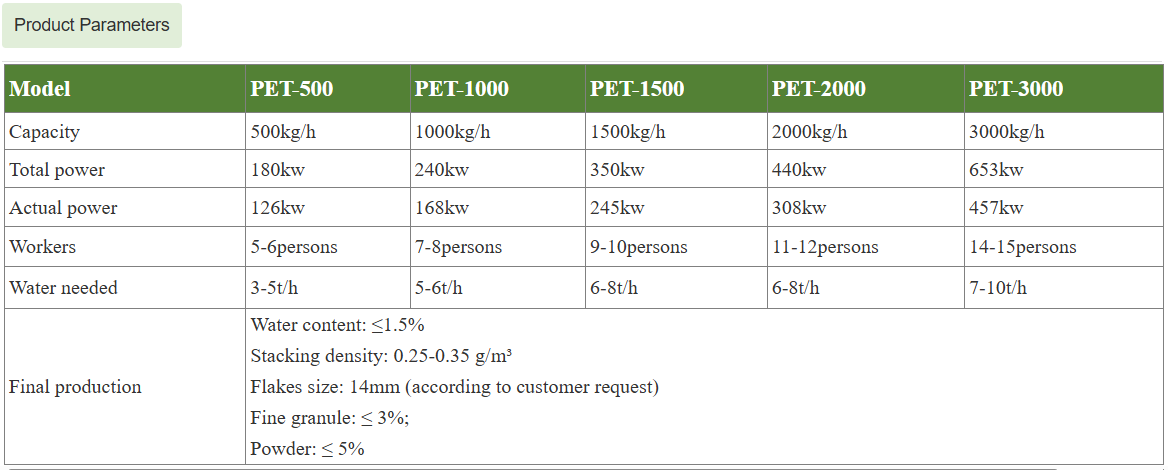

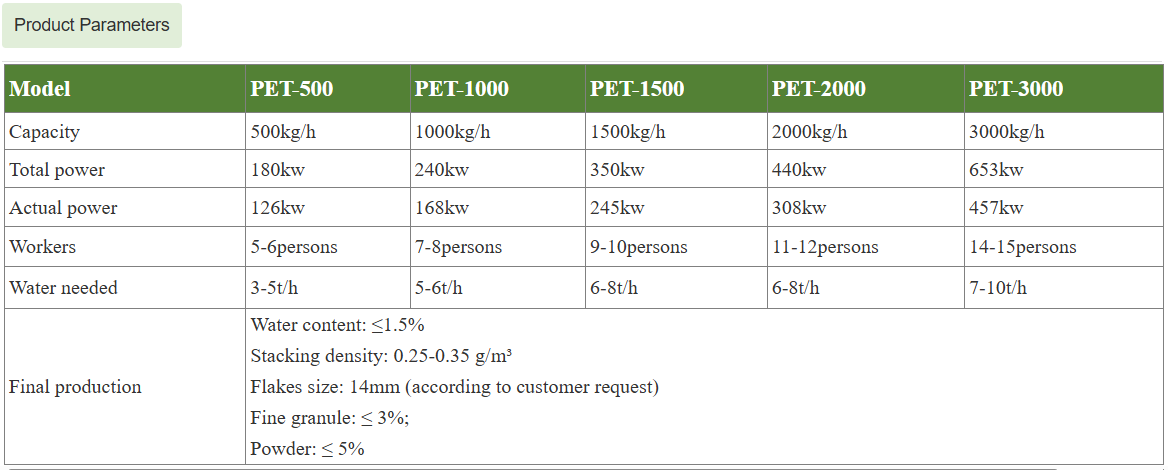

5. Production capacity: 500KG/H, 1000KG/H, 1500KG/H, 2000KG/H, 3000KG/H

Main Advantage:

1. Automotive line for recycling the PET bottles and other waste plastic profile, except the film.

2. The final product is the cleaning flakes, if you want the final product is pellets, we should equip the granulator line again.

Features:

Capacity: 500-3000kg per hour

Moisture of PET Flakes: Less Than 2%

Cap &Label separate with the PET bottle flakes automatically

Bottle Types: PET Bottle, Plastic Bucket, Water Bottle, Coke Bottle,

Application: PET Strap, PET Yarn Fiber, PET Sheet

Detailed Photos

Detailed Photos

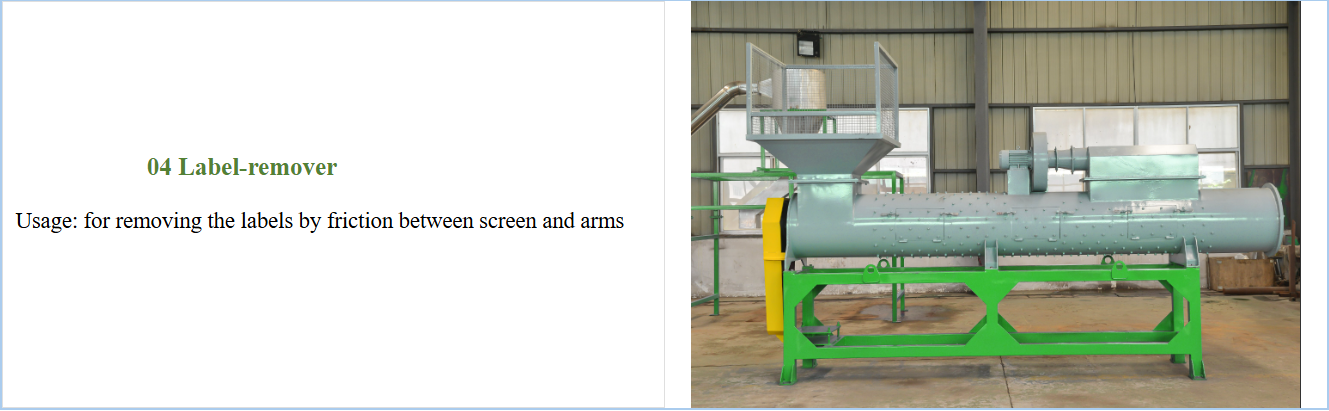

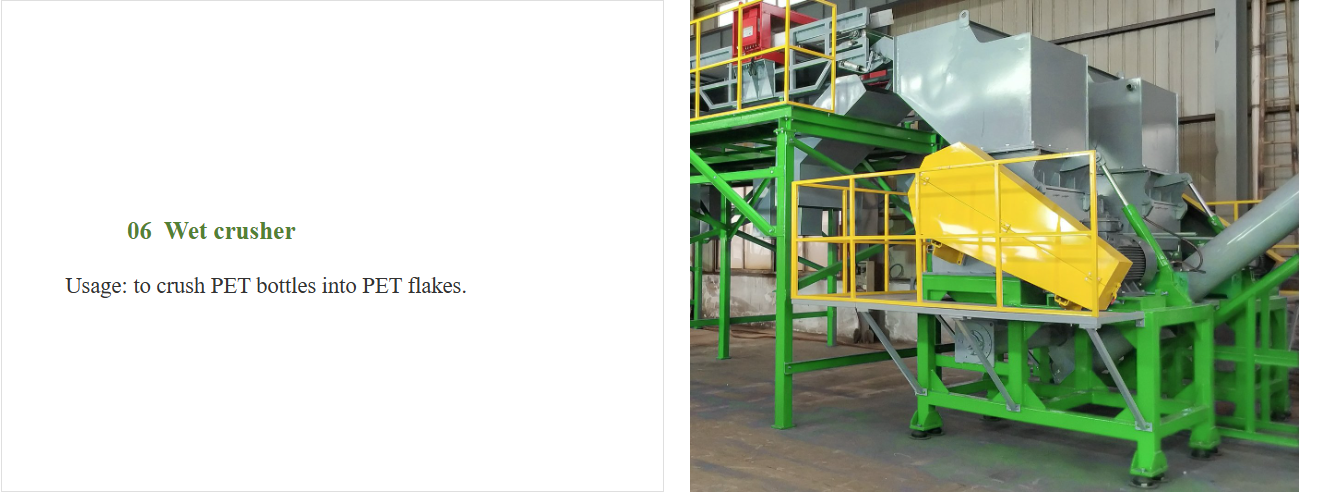

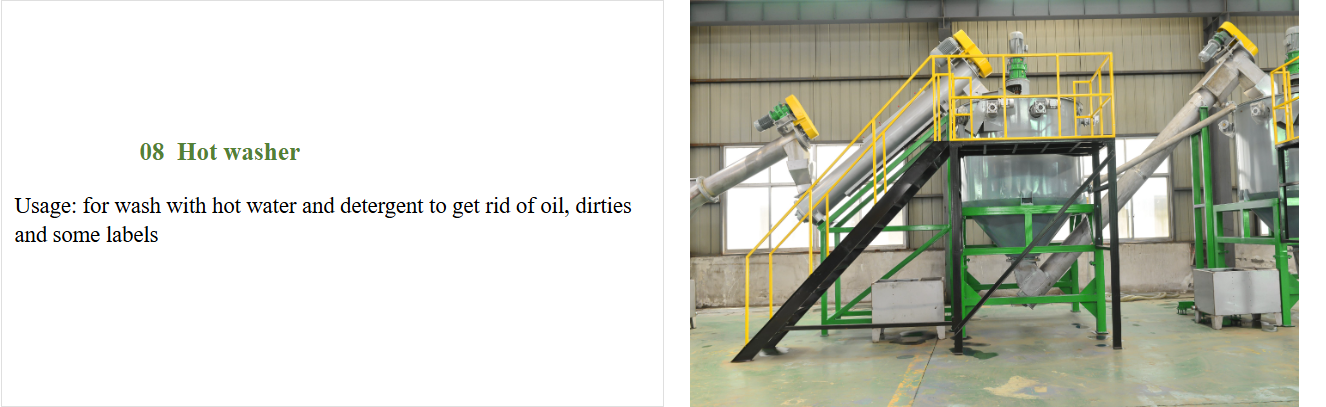

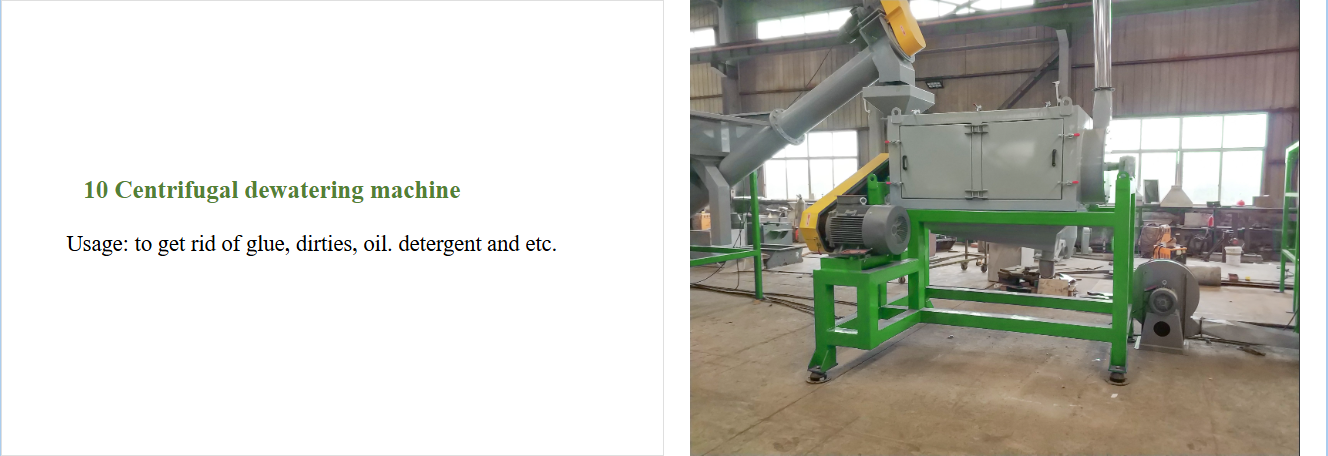

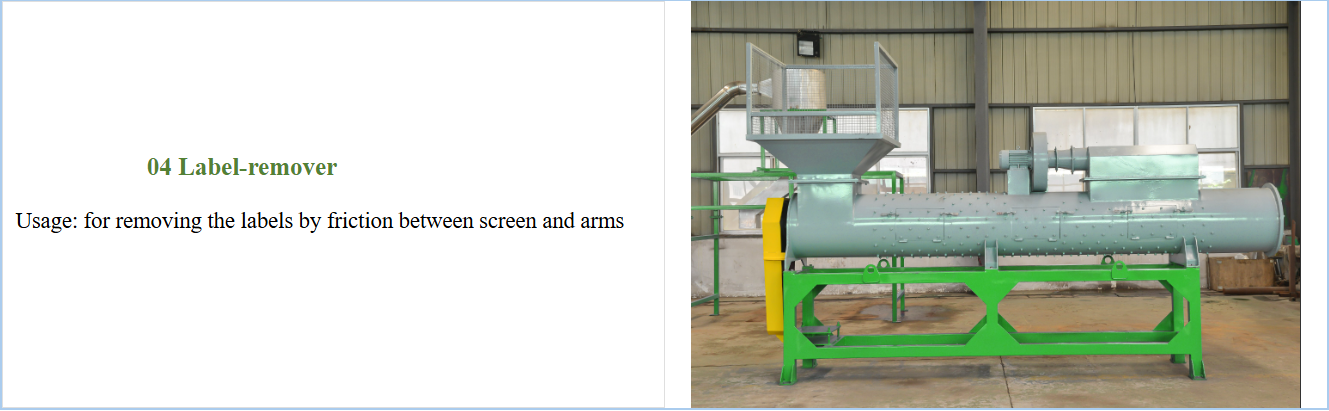

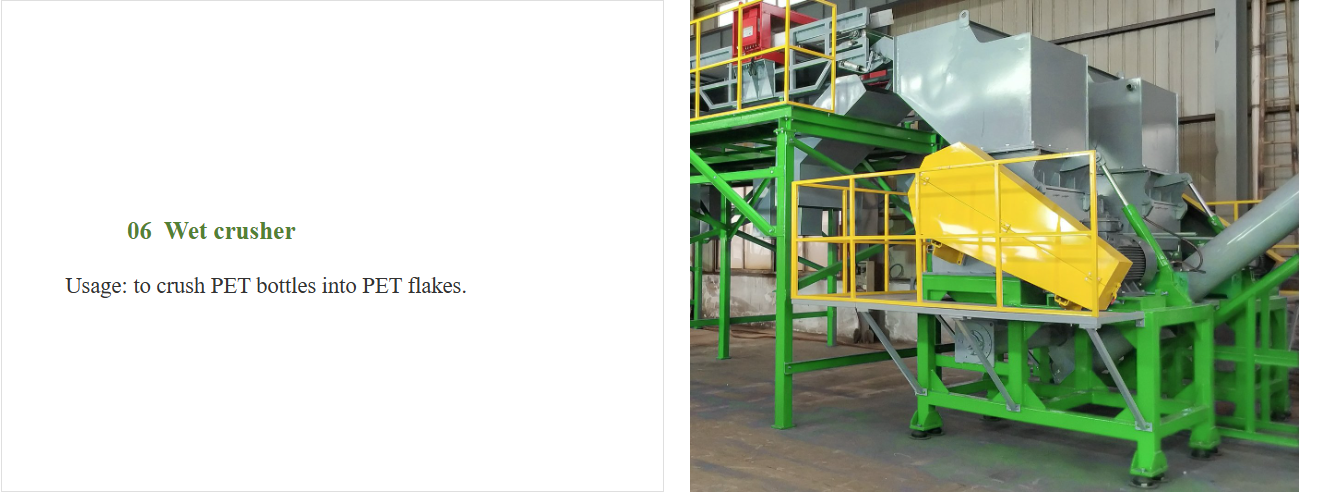

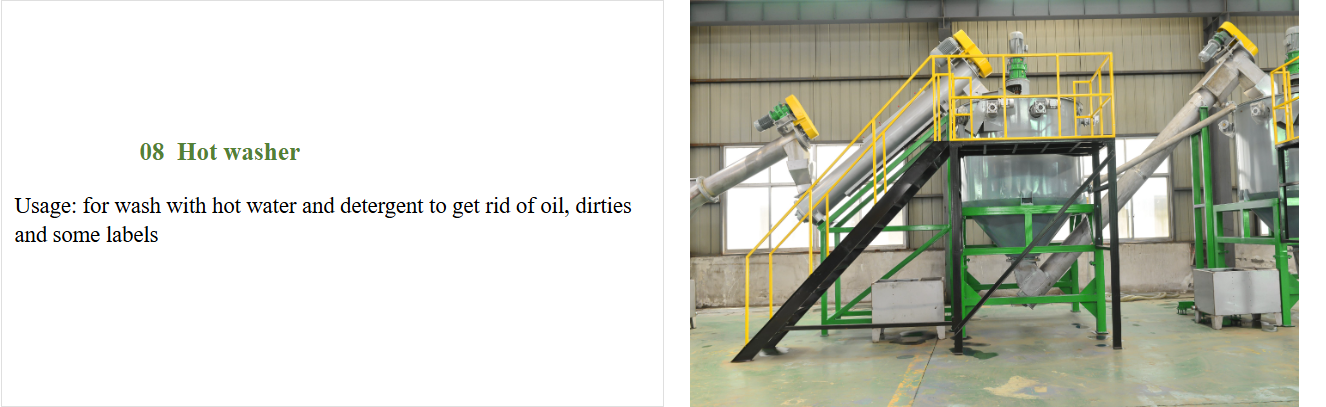

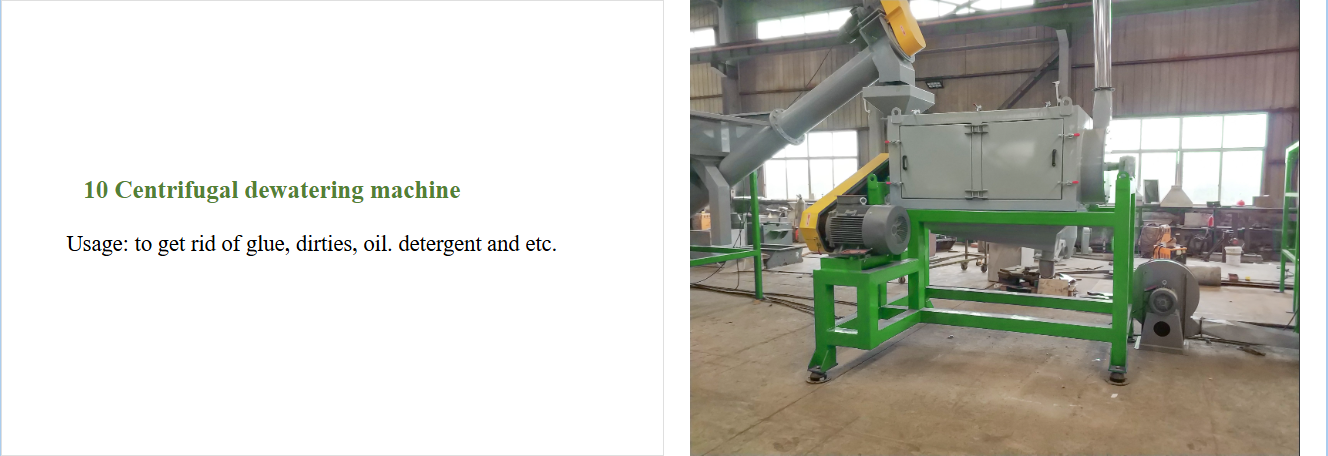

The production line includes: De-baler, belt conveyor, trommel, label remover, sorting table, crusher, floating washing tank, screw feeder, hot washer, high speed friction washing machine, centrifugal dewatering machine, dryer blower and label seperator, silo, electric cabinet etc.

01 Metal chain conveyor

Usage: Cut the bundled PET bottles of wire, through the chain conveyor to the unpacking machine unpacking

02 De-baler

Usage: Manully cut off the packaging steel line of the packaged bottles. then put them into the debaler. The packaged bottles will opened by the running screw blade and run ahead to exit.

productive process

Company Profile

Company Profile

Q: How can we get the exact price of plastic machine?

A: Contact us with bottle volume and capacity request. Then we will recommend you suitable model machine soon.

Q: Do you provide any spare parts with machine?

A: Yes, we offer all necessary spare parts together with machine sending and 3 days spare parts delivery after machine sale.(contact us for packing list )

Q: How about your after-sale service?

A: We offer manual instruction and engineer training before loading, after shipment we provide 24 hours online support, video technical support or field installation assist.

Q: What is the lead time?

A: We have standard model machine in stock.It can be delivery within 1 week. If need to make mould, the delivery time need half month after drawing confirmed.

Q: What is the warranty period for your machine?

A: 12 months warranty for components and technical support.

Q: Do you provide custom machines?

A: Most of our machines are customized. Our goal is efficiency and stable performance. We design the machines according to customers products to meet customer' needs.

Q: What's the advantage of SINO-TECH?

A: We provide customers with turnkey projects. Including plant design, blow molding machine and mold installation, debugging, also we can source the auxiliary equipment for customers. We can ship the full set of machines after testing in our factory. It will save a lot of cost and time for customer.

Q: How can we get the exact price of plastic machine?

A: Contact us with bottle volume and capacity request. Then we will recommend you suitable model machine soon.