A plastic extrusion line changes raw plastic into finished shapes. These shapes are used in many everyday things. The plastic extrusion process has several important steps:

Operators put raw plastic pellets or flakes into a hopper.

The material moves into a barrel that is heated.

A strong screw pushes and melts the plastic.

The melted plastic goes through a screen to take out impurities.

The material moves into a custom die, which shapes it.

The shaped plastic cools and gets hard as it leaves the die.

Plastic extrusion is very important for making many plastic products. These include construction pipes, packaging sheets, and profiles. Many industries use this process and other machines, like blow molding machines. They need these to keep up with the need for strong and reliable materials.

Key Takeaways

Plastic extrusion changes raw plastic pellets into shapes like pipes, sheets, and films. It does this by melting, shaping, cooling, and finishing the plastic.

A plastic extrusion line has important parts. These include the extruder, die, cooling systems, take-up units, and control systems. All these parts work together to make strong and even products.

Common plastics used are polyethylene, polypropylene, PVC, and PETG. Each is picked for its strength, flexibility, and ability to resist chemicals or weather.

Plastic extrusion is used in packaging, construction, transportation, and home decoration. It helps make tough, custom-shaped products fast and at a low cost.

New technology and recycling help plastic extrusion use less energy and be better for the environment. This helps factories save money and protect nature.

Plastic Extrusion Line

Main Components

A plastic extrusion line has many machines and systems. These help change raw plastic into finished products. Each part has a special job in the plastic extrusion process. The main components are:

Extruder: This machine melts and mixes plastic pellets. It has a screw, barrel, motor, and heaters. The screw pushes the plastic through the barrel. The plastic heats up and mixes until it is molten.

Die Assembly: The die shapes the melted plastic. It can make pipes, sheets, or films. Different dies make different shapes for each product.

Cooling Systems: Water baths, air coolers, and chill rolls cool the plastic fast. Cooling helps the product keep its shape and strength.

Take-up Units: These units pull, wind, or cut the finished plastic. They help handle the product after it leaves the die.

Ancillary Equipment: Machines like air rings, edge trimmers, and corona treaters help improve quality. They can also add special features.

Control Systems: These systems watch temperature, pressure, and speed. They help keep the plastic extrusion process steady and the product even.

Note: SINOTECH Machinery Co., Ltd. makes plastic extrusion lines with smart control systems and strong parts. Their machines help many industries, like packaging and construction.

Component | Function in Extrusion Process |

Extruder | Melts and mixes plastic pellets |

Die Assembly | Shapes molten plastic |

Cooling Systems | Solidifies and stabilizes product |

Take-up Units | Handles and finishes product |

Ancillary Equipment | Adds features and improves quality |

Control Systems | Maintains process stability |

How It Works

The plastic extrusion process starts when workers put plastic pellets in the extruder. The screw inside moves the pellets forward. Heaters melt the pellets as they move. The melted plastic goes through the barrel and reaches the die. The die shapes the plastic into a long form, like a pipe or sheet.

Cooling systems make the shaped plastic hard fast. This step is important for keeping the product strong and stable. Take-up units pull or wind the cooled product. This gets it ready for cutting or storage. Control systems check temperature, pressure, and speed. They help stop problems and keep the process running well.

A good plastic extrusion line, like those from SINOTECH Machinery Co., Ltd., uses smart technology to watch machine conditions. This helps lower downtime and saves energy. Upgrading old machines with servo motors or hybrid units can make them work better. Good equipment keeps production speeds steady and product quality even. Other machines, like blow molding machines and plastic recycling lines, work with extrusion lines to help make many products.

Plastic Extrusion Process

Material Preparation

Operators start by getting the plastic ready. They use pellets, flakes, or powders. These come in bags or big containers. Machines like vacuum loaders and hoppers move the plastic to the extruder. Dryers and dehumidifiers take out water from the plastic. This stops problems in the final product. Clean, dry, and even plastic is important. Good preparation helps make strong plastic products.

Tip: SINOTECH Machinery Co., Ltd. has special machines for moving and drying plastic. These help factories keep their products good from the beginning.

Melting and Mixing

Next, the plastic must melt and mix well. The extruder has a screw inside a hot barrel. The screw turns and pushes the plastic forward. The screw and barrel rub together and make heat. Heaters also help melt the plastic. Both work together to melt the plastic fast.

The extruder needs to make the melted plastic even and smooth.

Too much heat or pressure can hurt the plastic.

Careful control of heat and pressure makes better products.

Melt pumps help keep pressure and flow steady.

Static mixers after melt pumps mix the plastic more.

Special tools watch pressure and thickness all the time.

Other machines, like temperature controls and dosing systems, help keep things steady. These make sure the plastic melts and mixes the right way. This is important for making good products.

Shaping and Cooling

After melting, the plastic gets its shape and cools down. The hot plastic goes through a die to get its shape. Dies can make pipes, sheets, or other shapes. Molds and tools help keep the right size and shape while cooling.

Cooling is very important in this step. Water baths, air coolers, or chill rolls cool the plastic fast. Fast-moving water or air helps cool the plastic better. Jets, bubblers, and baffles in tanks help move the water. Rollers and pullers stretch and fix the product’s size.

Molds keep the shape and size right during cooling.

Cooling near the die stops the shape from changing.

Water tanks with moving water cool the plastic fast.

Rollers help cool and set the size.

Air sprays blow cold air to cool the surface.

Even cooling stops problems and keeps the product strong.

Factories change cooling methods for different products. SINOTECH Machinery Co., Ltd. makes cooling systems that work well and make good products.

Cutting and Finishing

The last step is cutting and finishing the product. After cooling, the product goes to cutters. These cut it into the right size or shape. CNC machines, mills, lathes, drills, grinders, and tapping tools finish the product. These tools make the surface smooth and the size correct.

Process | Description | Role in Ensuring Consistency |

CNC Machining | Machines like lathes, grinders, and mills work by computer. | Programs control speed and tools for fast, repeat work. |

Milling | Rotary cutters make threads, slots, and shapes. | Finishes features and makes sizes more exact. |

Turning | The piece spins while a tool cuts it. | Computer programs keep shapes and sizes the same. |

Drilling | Rotating cutters make holes in the product. | Makes holes the same every time, which is important for assembly. |

Grinding | Abrasive wheels or belts smooth the surface. | Makes the surface smooth and the size just right. |

Tapping | Tools cut threads inside holes. | Makes threads for screws or bolts, and computers help keep them even. |

Finishing steps like polishing, grinding, and deburring remove rough spots. Heat and flame polishing make the surface clear and fix tiny flaws. These steps help the product look good and last longer.

Note: Extra machines, like robots and part movers, help with cutting and finishing. These make the work faster and more even.

Polymer Extrusion Process Materials

Common Plastics Used

There are many kinds of plastic used in the polymer extrusion process. Some plastics are used more often than others.

Polyethylene (PE) comes in LDPE and HDPE. LDPE bends easily and is strong. HDPE is very strong and does not get damaged by chemicals. Both are used for packaging, pipes, and films.

Polypropylene (PP) is light and tough. It does not melt easily and can handle chemicals. Factories use it for car parts, containers, and fibers.

Polyvinyl Chloride (PVC) is hard and strong. It does not get damaged by acids or bad weather. Companies use it for pipes, window frames, and cables.

Polystyrene (PS) is easy to shape and keeps heat in. It is used for food packaging and foam things.

PETG is clear, strong, and does not break easily. It is good for bottles, medical parts, and display packaging.

Nylon is tough and bends without breaking. It is used for tubing, gears, and special parts.

Note: SINOTECH Machinery Co., Ltd. makes extrusion lines that work with these plastics and more. Their machines also help with blow molding and plastic recycling.

Why These Materials

Factories pick these plastics because each one is good for different jobs in the polymer extrusion process. Polyethylene is cheap, bends well, and does not get damaged by chemicals. Polypropylene is strong and can take heat. PVC lasts a long time and does not get ruined by weather, so it is good for building things. Polystyrene is simple to use and keeps heat in, which is helpful for packaging and electronics. PETG is clear and tough, so it works well for medical and food packaging.

The table below explains why these plastics are good for extrusion:

Plastic | Key Properties | Common Uses |

LDPE | Bends easily, does not get damaged by chemicals | Bags, films, tubing |

HDPE | Very strong, does not rust | Pipes, bottles, containers |

PP | Light, does not melt easily | Car parts, packaging |

PVC | Hard, does not get ruined by weather | Pipes, window frames, cables |

PETG | Clear, does not break easily | Bottles, medical packaging |

PS | Easy to shape, keeps heat in | Food trays, insulation |

Factories choose the right plastic by thinking about what the product needs. They look at how strong or bendy it should be and how it will be used. Picking the right plastic helps stop problems and saves money. SINOTECH Machinery Co., Ltd. helps customers choose the best material for their extrusion line. This makes sure every product is high quality.

Applications of Plastic Extrusion

Plastic extrusion turns raw plastic into useful things. Many industries use these products every day. Factories use this process to make items people see and use. SINOTECH Machinery Co., Ltd. gives advanced extrusion lines to these industries.

Packaging

Plastic extrusion makes packaging that keeps goods safe. Factories make containers, films, and sheets from plastic. These help keep food fresh and clean. Stores use plastic profiles for signs and displays. The process also makes thin films for bags and wraps.

Plastic containers for storage

Thin films for food packaging

Plastic profiles for store displays and signs

Flat sheets for packaging

Plastic packaging from extrusion is light and strong. It is also clean and safe for food. SINOTECH Machinery’s lines help companies meet food safety rules.

Construction

Builders use plastic extrusion for strong building materials. Factories make pipes, window frames, doorframes, and roof trims. These parts do not rust and last longer than wood or metal. Custom extrusion lets companies make special shapes for building.

Construction Product | Main Use |

Pipes | Plumbing and water delivery |

Window and door profiles | Frames and trims |

Roofing profiles | Cladding and roof trims |

Decorative trims | Edges and stair protectors |

SINOTECH Machinery has extrusion lines for PVC, PP, ABS, and PE. These plastics are common in building.

Transportation

Plastic extrusion shapes parts for cars and roads. Factories make air ducts, cable covers, and bumpers. Road safety items like guardrails and warning posts use extruded plastic. These products help keep roads safe and cars working well.

Custom extrusion lets companies design parts for transport needs.

Home and Decoration

Plastic extrusion makes things that improve homes. Factories make PVC floors, wall panels, ceiling panels, and roof tiles. These are strong, resist water, and look nice. Extruded profiles also shape window frames and fake marble sheets.

PVC floors

Wall panels

Ceiling panels

Roof tiles

Artificial marble sheets

SINOTECH Machinery’s lines help the home decoration industry with good solutions.

Other Uses

Plastic extrusion helps many other industries too. Factories make medical tubes, irrigation pipes, lab tools, and electrical parts. Extruded profiles also shape signs, bumpers, and parts for planes and electronics.

Medical tubes and catheters

Irrigation pipes for farms

Lab equipment parts

Electrical insulation parts

Sign and display trim

SINOTECH Machinery Co., Ltd. gives extrusion lines and other machines. These include blow molding machines and recycling lines for many needs.

Tip: Companies can ask SINOTECH Machinery for custom plastic extrusion solutions for their needs.

Benefits and Considerations

Advantages

Plastic extrusion has many good points for factories. The process keeps running, so factories make long pieces fast. This helps them fill big orders quickly. Companies use many kinds of plastics and make lots of shapes and sizes. Custom plastic extrusion works well for many jobs.

Here is a table with the main benefits:

Advantage | Explanation |

High Efficiency | The process runs all the time and makes long products fast. |

Flexibility | It works with many materials and shapes for custom plastic extrusion. |

Low Costs | Making lots of products lowers the price for each one. |

High Quality | The process makes even shapes and keeps quality high. |

Co-extrusion | It mixes different materials in one product for special features. |

Factories save money because they make little waste. They can use leftover plastic again. This helps the planet and cuts costs. Changing the product before it gets hard gives more ways to design things.

Limitations

Plastic extrusion has some problems too. Not every material works well in this process. Some plastics break or get weak when heated. The process is best for things with the same shape all the way, like pipes or sheets. It does not work well for making tricky 3D shapes.

Note: Factories must pick the right material for plastic extrusion. Materials that cannot take heat or pressure are not good. This means some products cannot be made.

Innovations

New ideas have made plastic extrusion better and greener. Twin-screw extruders help recycle plastic by taking out water and keeping it strong. Factories mix recycled plastic with bio-based materials to make better and greener products. Energy-saving systems, like infrared heaters and closed-loop cooling, use less power and water.

Many companies use custom plastic extrusion to make eco-friendly things for packaging, building, and healthcare. SINOTECH Machinery Co., Ltd. gives advanced extrusion lines, blow molding machines, and recycling lines to help these changes. These new things help factories make more products, save energy, and reach recycling goals.

The plastic extrusion line changes raw materials into finished products by following these main steps:

Workers put raw material into the extruder hopper.

A screw turns and melts the plastic while mixing it.

The melted plastic gets pushed through a die to shape it.

The shaped plastic cools down so it stays strong.

Machines cut and finish the product to match what is needed.

Plastic extrusion is useful for many reasons:

Factories make special shapes for building, cars, and packaging.

The process lets companies make lots of products quickly and cheaply.

It works with many kinds of raw materials and tricky designs, so it is good for jobs that need exact and tough products.

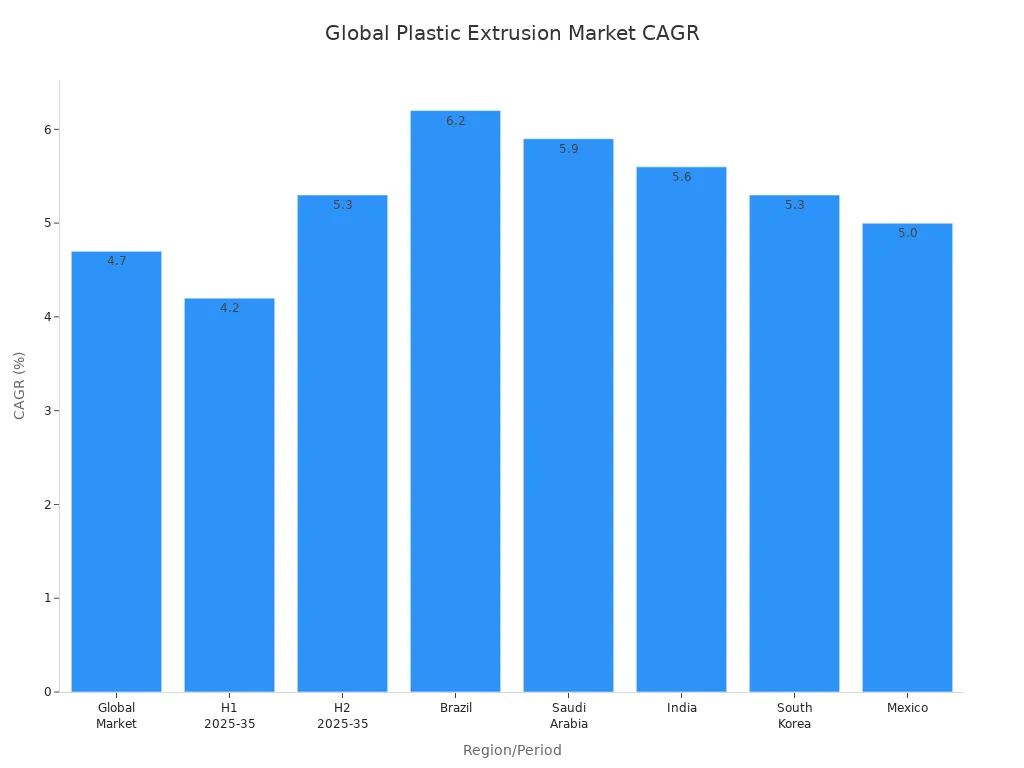

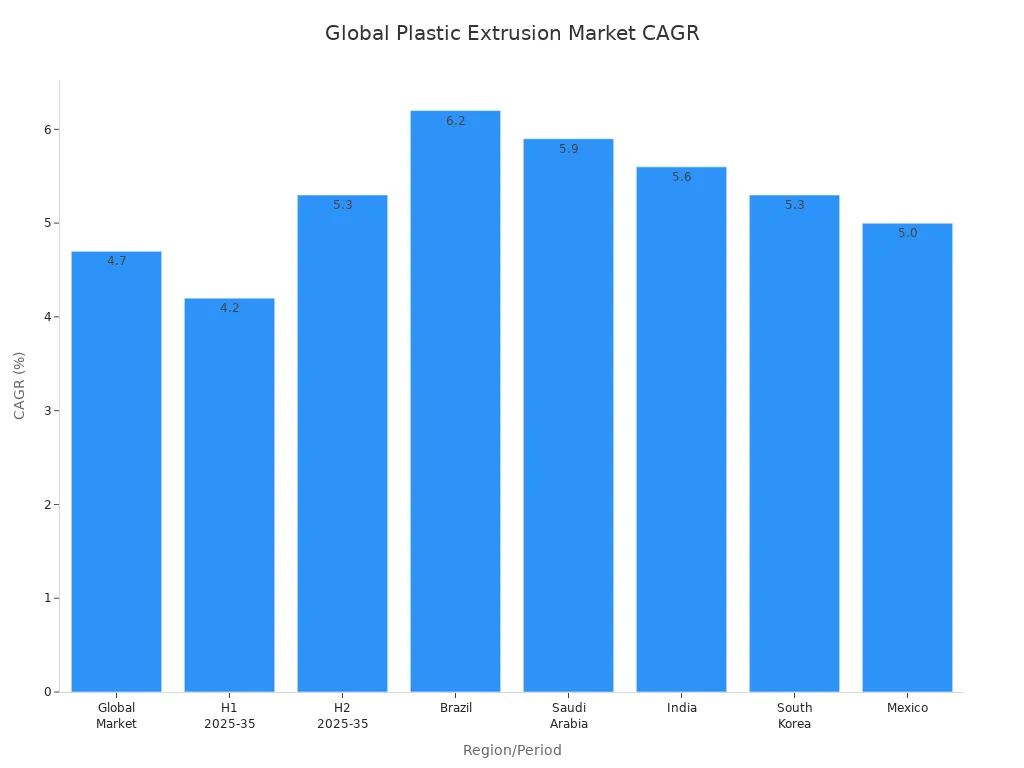

New ideas like smart controls, changeable extruder parts, and earth-friendly materials help the industry grow. The world market will keep getting bigger, especially as companies such as SINOTECH Machinery Co., Ltd. give better plastic extrusion lines, blow molding machines, and recycling machines. Factories can count on SINOTECH Machinery for good solutions and expert help as the industry changes.

FAQ

What products can a plastic extrusion line make?

A plastic extrusion line makes pipes, sheets, films, and profiles. It also makes packaging materials. Many industries use these products every day. Construction, packaging, and transportation all need them. Home decoration uses them too. SINOTECH Machinery Co., Ltd. gives custom solutions for each job.

How does SINOTECH Machinery ensure product quality?

SINOTECH Machinery uses smart control systems and strong machine parts. Their machines check temperature, pressure, and speed all the time. This helps every product stay the same and work well. Customers get help and training to use the machines right.

What materials work best in plastic extrusion?

Factories use polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), and PETG. These plastics are strong and bend without breaking. They also do not get damaged by chemicals. SINOTECH Machinery’s lines work with many raw materials for different jobs.

Can plastic extrusion lines support recycling?

Yes! Many SINOTECH extrusion lines use recycled plastics. Factories can use a plastic recycling line to reuse waste. This helps the planet and saves money for the factory.

How can companies choose the right extrusion equipment?

Companies should think about what product they want to make. They also need to know what material and how much they will make. SINOTECH Machinery Co., Ltd. gives advice and helps plan the plant. Contact their team for a free talk and a special solution.

Need help with plastic extrusion or blow molding machines? Visit SINOTECH Machinery’s product page for more information and expert support.