Plastic sea balls blow molding moulding Machine making machine

Product Introduction

The Plastic Sea Balls Blow Molding Machine is engineered for the efficient production of high-quality plastic sea balls used in recreational and amusement industries. This versatile machine is capable of manufacturing plastic balls with diameters ranging from 20mm to 120mm. Additionally, it can produce 1-5L plastic bottles such as milk, yogurt, detergent, shampoo bottles, and more.

Designed for high-speed, reliable production, the machine supports a variety of materials including PP, PE, HDPE, LDPE, and PVC. It offers flexibility with different configurations, including single, double, triple, and four-head die-head options, providing flexibility to meet diverse production demands.

Product Features

Flexible Production

While optimized for plastic sea balls, this machine can also produce bottles, containers, and other plastic products for sectors like cosmetics, food, and chemicals.

Efficient Output

The double-station system allows the machine to produce 1800-2000 sea balls per hour, equating to approximately 43,200-48,000 balls daily, offering high productivity for large-scale manufacturing.

Customizable Die-Head System

The machine comes with a double die-head system, but can also be configured with single, triple, or four-head die heads, allowing for tailored production based on the product size and production volume.

Product Advantages

Quick Cycle Time

With a cycle time of 20 seconds, the machine ensures rapid production, reducing idle time and enhancing overall output.

Precise Parison Control

The MOOG parison control system provides accurate control over wall thickness, ensuring consistent quality and minimizing material waste. It also allows for manual adjustments to die gaps for added flexibility.

Long-Lasting Molds

The machine’s molds are made of Aluminum 7075# with Beryllium Copper or 4Cr13 stainless steel, ensuring durability and efficient cooling for sustained high performance.

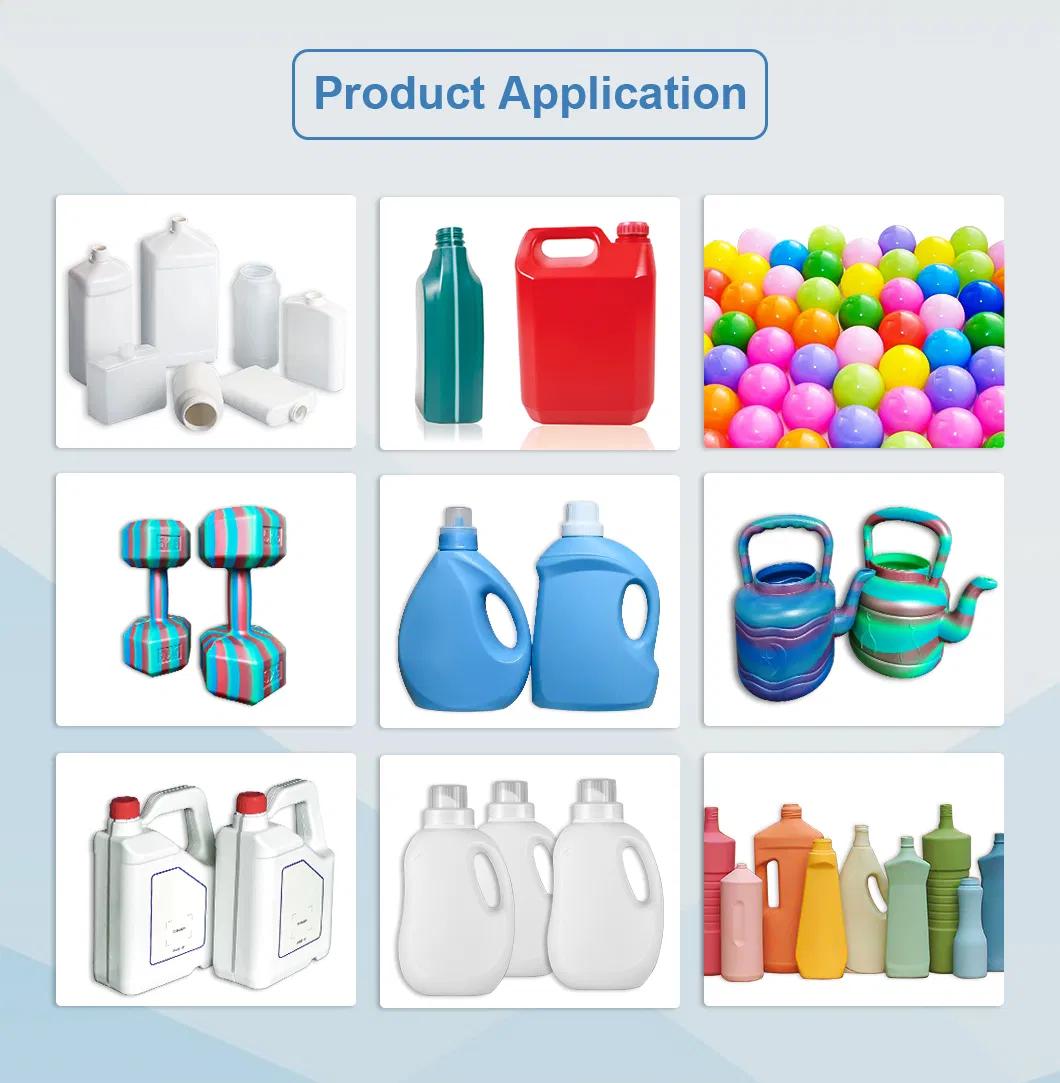

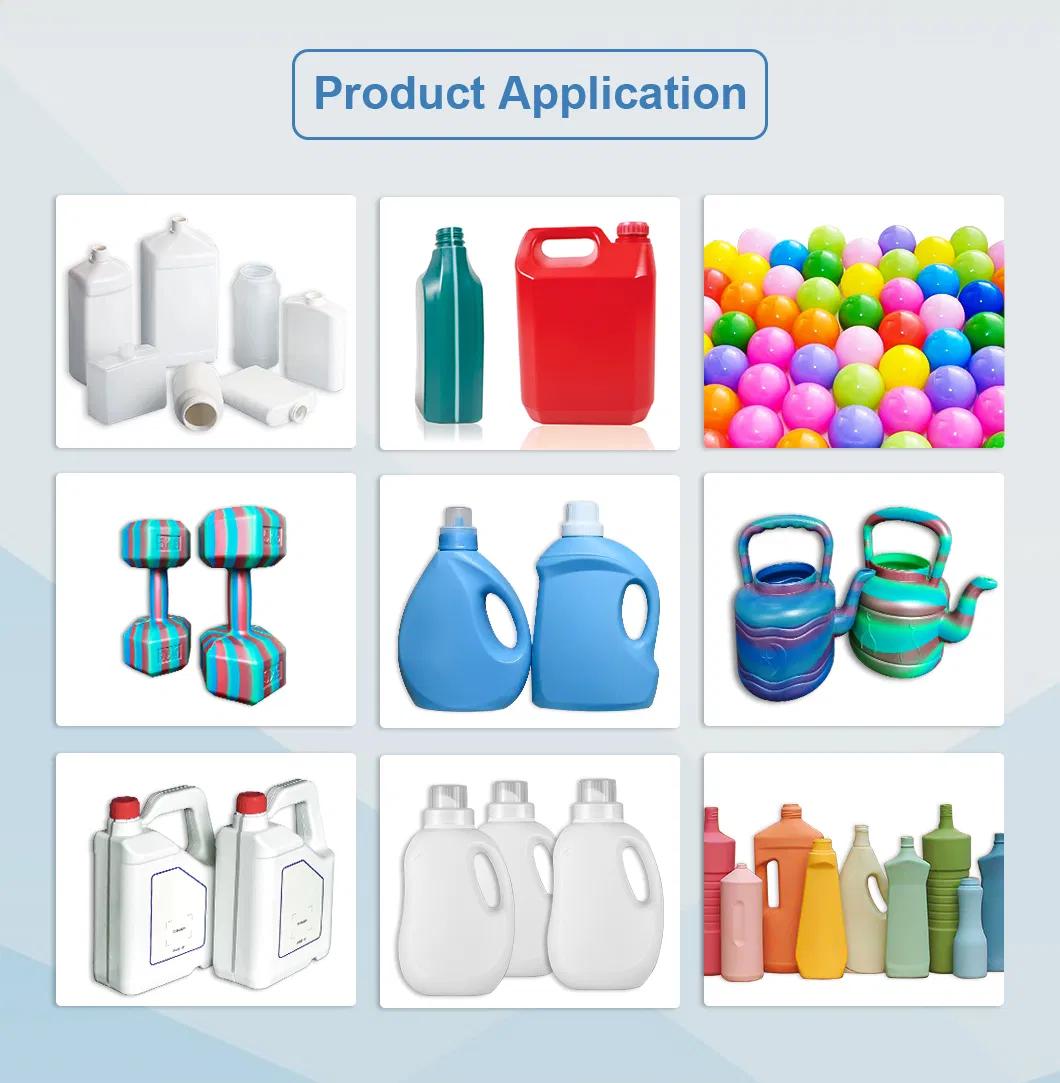

Product Application

The Plastic Sea Balls Blow Molding Machine is ideal for producing:

Plastic Sea Balls: Used in water parks, amusement centers, and beach resorts for recreational purposes.

Plastic Bottles: The machine can also be used for producing milk/yogurt bottles, detergent bottles, shampoo bottles, and household plastic containers.

Chemical Containers: The machine’s versatility makes it ideal for producing chemical storage bottles and industrial packaging.

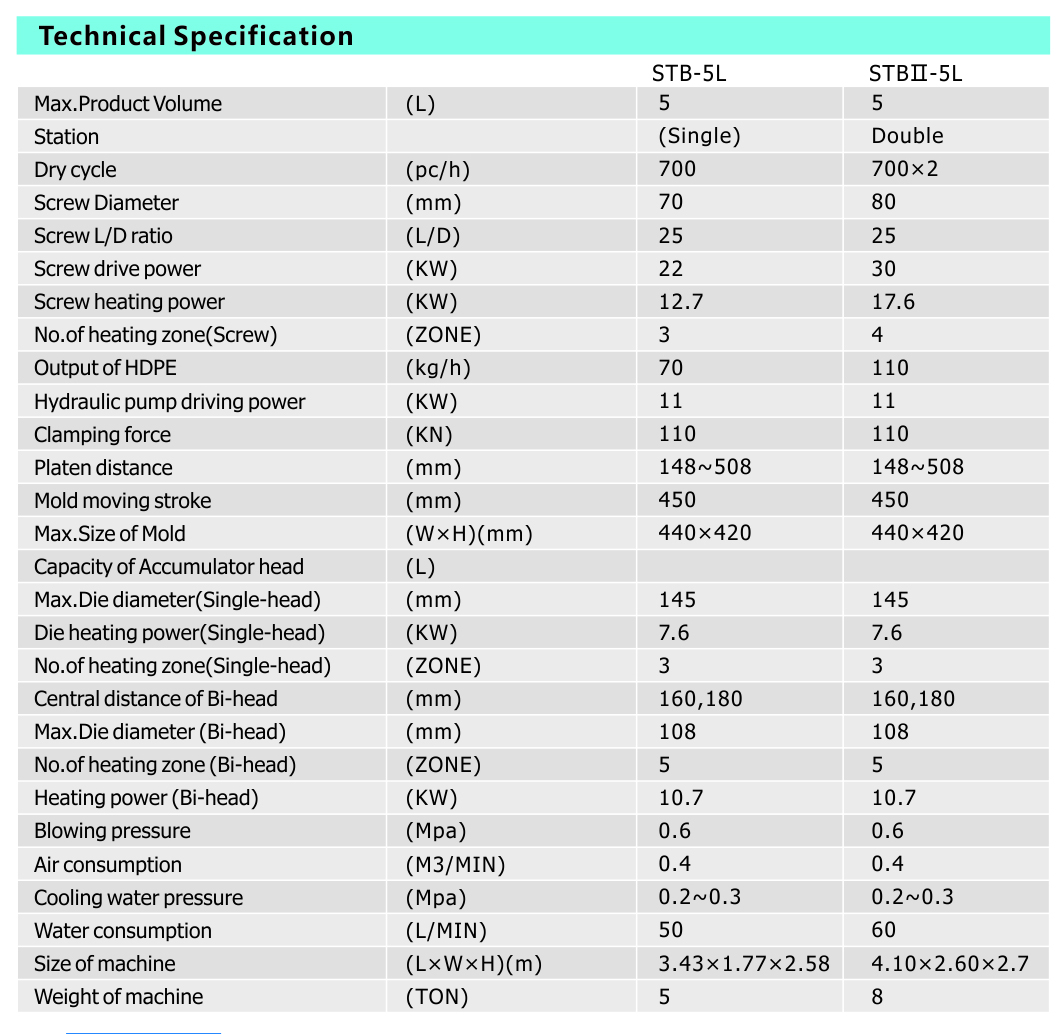

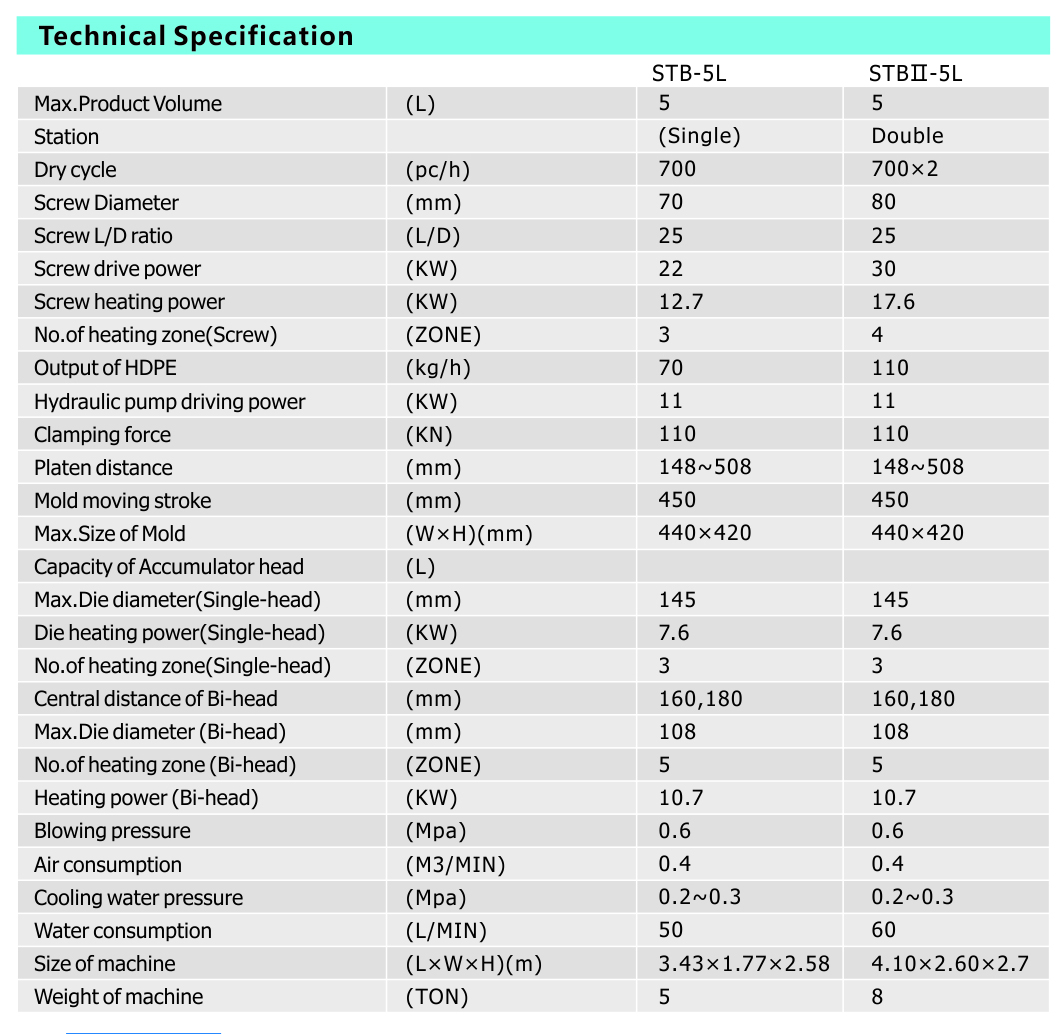

Product Parameters