Product Introduction

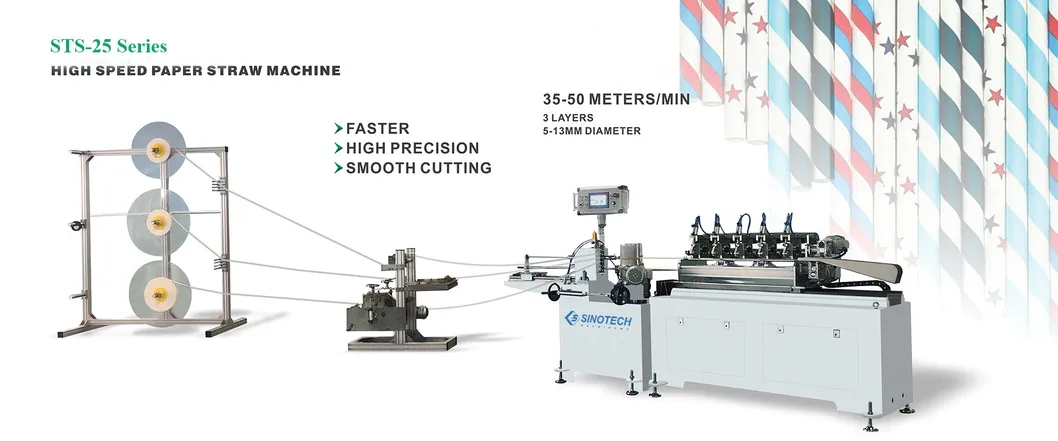

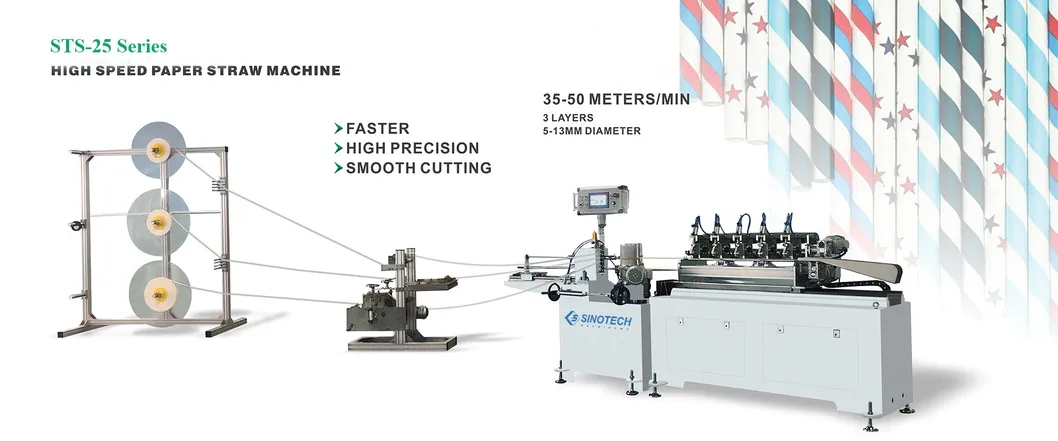

The High-Speed Paper Straw Making Machine is engineered for producing a wide range of paper straws and small paper tubes with high efficiency. This machine combines raw material feeding, gluing, winding, and cutting into a seamless, fully automated process. The use of advanced PLC control and a touch screen interface makes operation intuitive, while servo-driven cutting systems ensure precision. Designed for the production of 5-12mm diameter paper straws with 0.5-1mm wall thickness, it offers customizable production speeds and low maintenance, making it ideal for businesses seeking cost-effective, sustainable solutions for paper straw manufacturing.

Product Features

Integrated Automated Production

This machine offers a fully integrated solution for paper straw production. From raw material feeding to winding and cutting, every stage of the process is automated, significantly reducing labor costs and enhancing efficiency. The use of multi-blade cutting ensures fast, precise cuts, minimizing material waste and maximizing production output.

High-Speed and Flexible Operation

With adjustable speeds ranging from 30 to 45 m/min, this machine is designed for high-volume production. The servo synchronous tracking system provides accurate, real-time adjustments during the cutting process, ensuring high precision regardless of the paper straw size, whether 6mm, 8mm, or 10mm.

Durability and Hygiene

Constructed with stainless steel, both the machine body and main components are designed to meet hygienic standards and ensure environmental sustainability. This robust construction ensures long-term reliability, while the design also simplifies maintenance and cleaning, making it suitable for continuous operation.

Product Advantages

Efficient and Cost-Effective Production

The High-Speed Paper Straw Making Machine offers a low-maintenance, high-speed solution for producing paper straws. By integrating cutting-edge servo motors and PLC control systems, it reduces operational downtime and enhances production efficiency, leading to cost savings and improved output consistency.

Versatile and Customizable

The machine can produce various paper straw sizes from 5mm to 12mm in diameter, offering flexibility to cater to different market needs. The gluing system is designed to handle single-side gluing, ensuring clean and uniform coating, while the machine's ability to handle multiple layers of materials allows for flexibility in production.

Reliable Components for Long-Term Operation

The use of top-quality electrical components from renowned brands like Siemens, Schneider, and Airtac guarantees high performance, safety, and long-term reliability. The servo-driven cutting system ensures precise cuts, while the multi-blade cutting system enhances production efficiency, reducing waste.

Product Parameters

| Parameter | Value |

| Tube Diameter | 5-12 mm |

| Wall Thickness | 0.5-1 mm |

| Winding Speed | 30-45 m/min |

| Cutting Method | 6 Multi-Blade |

| Gluiing Method | Single Side |

| Air Pressure | 0.6 Mpa |

| Power Supply | 380V * 3P / 50Hz |

| Main Motor Power | 3 kW |

| Servo Motor | Teco, Taiwan |

| PLC Controller | Siemens |

| Inverter | ABB, Switzerland |

| Machine Dimensions | 3000 x 1400 x 1450 mm |

| Weight | 2000 kg |

Product Application

The High-Speed Paper Straw Making Machine is ideal for the production of eco-friendly paper straws in various industries, including:

Food and Beverage: Perfect for manufacturing straws for beverages, juices, smoothies, and other drink containers.

Cosmetics: Suitable for producing paper tubes for cosmetic packaging, such as for lip balms, powders, and other small products.

Pharmaceuticals: Capable of producing small paper tubes for medical and pharmaceutical packaging, ensuring hygienic standards are met.

Eco-Friendly Packaging: With an increasing demand for sustainable packaging solutions, this machine is perfect for companies looking to shift from plastic to paper-based alternatives.

SINOTECH’s machine offers a reliable and cost-effective solution for businesses aiming to meet the growing demand for sustainable paper products.

FAQ

Q: What size paper straws can the machine produce?

A: The machine can produce paper straws with diameters ranging from 5mm to 12mm, and customizable wall thickness from 0.5mm to 1mm.

Q: What is the production speed of this machine?

A: The machine operates at speeds of 30 to 45 meters per minute, depending on the paper straw size and thickness.

Q: What are the key components used in this machine?

A: The machine is equipped with high-quality components from brands like Siemens, Schneider, Airtac, and ABB, ensuring reliable performance and durability.

Configuration of High Speed Paper Straw Making Machine

Technical Parameter | Number of roller | 3 layer |

Tube diameter | 5-12 mm |

Wall-thickness | 0.5-1 mm |

Core mould fixed | Flange chuck |

Winding head | 2 |

Cutting way | 6 multi-blade |

Gluing way | Single side |

Operator | 1-2 person |

Winding speed | 30-45 m/min |

Speed control | Inverter |

Cutting control | Servo Sync |

Air pressure | 0.6Mpa |

Power supply | 380V*3P/50Hz |

Straw collecter | Auto |

Angel correction | Auto by motor |

Language | English |

Control system | Main motor | 3 KW |

Reducer type | RV110-1:15 |

Conveyor reducer | RV 30/40-1:7.5 |

Servo motor | Teco, Taiwan |

Servo driver | Teco, Taiwan |

PLC controller | Siemens |

Touch screen | Siemens |

Inverter | ABB Switzerland |

Electric part | Siemens |

Single part | ABB |

Pneumatic part | AIRTAC |

Fix length way | Encode |

Configuration | Paper reel stand | 3 layers |

Glue system | 3 layers |

Conveyor | 1 set |

Blades | 6 pieces |

Belts | 5 pieces |

Core mould | 2 set |

Useful tool | 1 set |

Measurement weight | Mainframe size | 3000*1400*1450 |

Area space | 6000*6000 mm |

Weight | 2000 KGS |

Sino-tech paper straw making machine as a ideal equipment for paper straws, with a high speed and stable capacity it is specially dedicated to spiral wind paper tubes of very small diameters.

The papaer straw making machine easy operating, and low maintenance cost and great flexibility make this machine perfectly suited for all paper tube manufacturer.

Sino-tech all machines equipped with top quality famous electrical parts and mechanical parts, such as Schneider, Siemens, Airtac etc. We also accept fully customizable according to your request.