5L fully Automatic extrusion blow moulding machine

Product Introduction

The 5L Fully Automatic Extrusion Blow Moulding Machine is designed to produce high-quality 5L plastic bottles efficiently and automatically. It serves industries such as beverages, chemicals, and household products, offering high precision and fast production cycles. With its advanced extrusion technology, the machine can process various materials, including HDPE, LDPE, and PP, ensuring excellent output for diverse applications. Automated operation minimizes operator input, maximizing productivity and cutting labor costs. Its robust hydraulic system and easy-to-use interface ensure reliable performance and cost-effective operation.

Product Features

Fully Automated System

The 5L Extrusion Blow Moulding Machine features a fully automated system, reducing the need for manual intervention and improving both speed and consistency. With an advanced PLC control system, the machine provides real-time monitoring and precise control, ensuring that production is efficient and error-free.

High-Speed Output

Capable of processing up to 70 kg/hr, this machine produces a high volume of bottles per hour. It is perfect for high-demand production lines, ensuring rapid throughput without compromising quality.

Versatile Material Compatibility

This machine supports a wide range of materials such as HDPE, LDPE, and PP, offering flexibility and adaptability for different market demands. Whether for beverages, chemicals, or household items, this machine can handle various material types efficiently.

Product Advantages

Precision Molding: With the MOOG 100-point parison thickness control, this machine ensures consistent wall thickness across all bottles, resulting in high-quality, durable products. This precision reduces material waste, improving overall efficiency and lowering production costs.

Energy-Efficient Design: The proportional hydraulic control system and auto lubrication mechanisms help reduce energy consumption while maintaining high performance. This makes the machine a cost-effective solution for businesses looking to reduce their operational expenses.

Easy Maintenance and Operation: The user-friendly control system, combined with an automatic lubrication system, ensures that the machine operates smoothly with minimal downtime. Additionally, the machine’s simple mold changeability reduces maintenance time and keeps production lines running without interruptions.

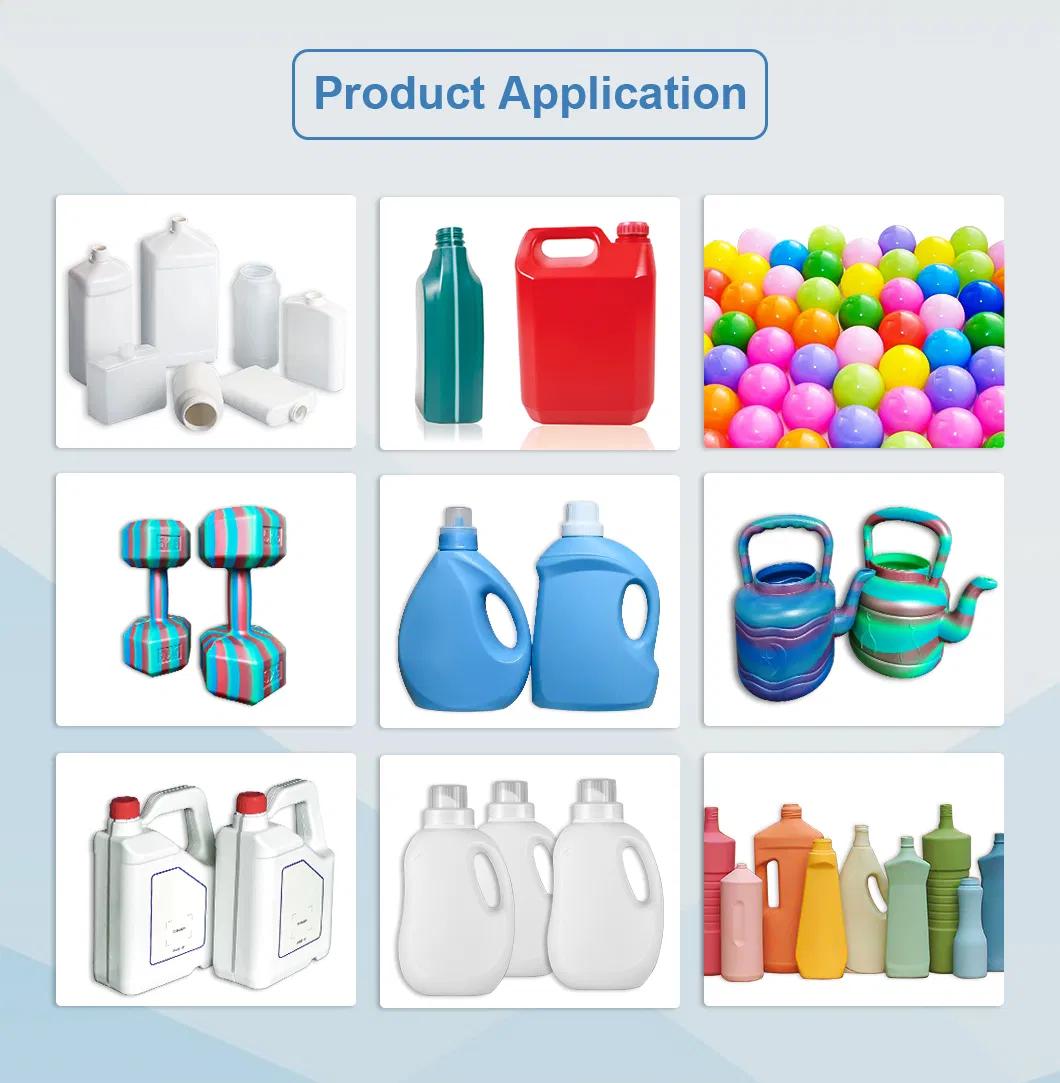

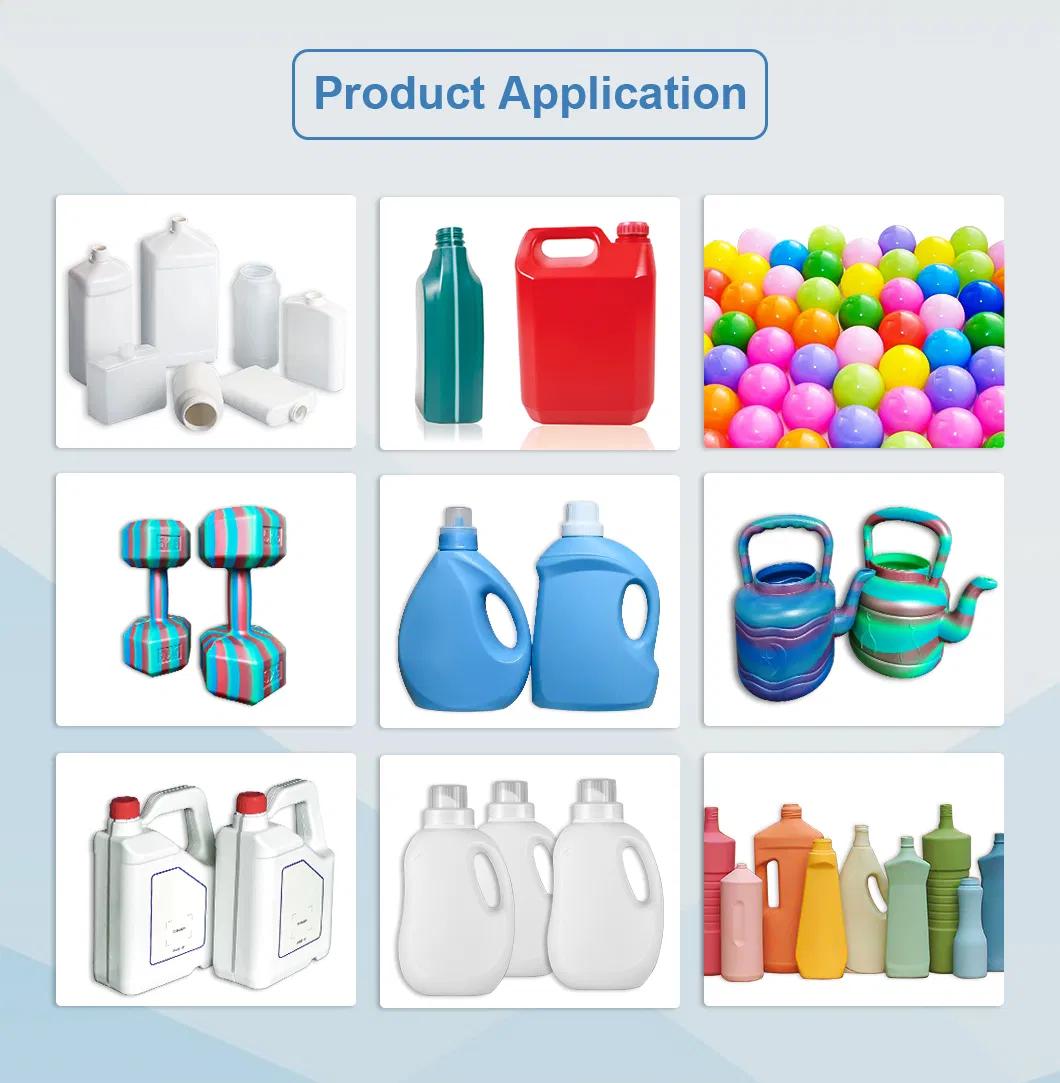

Product Application

Precision in Molding

Featuring the MOOG 100-point parison thickness control, this machine ensures uniform wall thickness across all bottles. This results in durable, high-quality products with minimal material waste, enhancing production efficiency and lowering overall manufacturing costs.

Energy Efficiency

The proportional hydraulic control system and auto lubrication mechanisms significantly reduce energy consumption while maintaining excellent performance. This makes the machine an ideal choice for businesses seeking to reduce energy costs and enhance operational efficiency.

Ease of Maintenance and Operation

The user-friendly control system and automatic lubrication system ensure smooth machine operation with minimal downtime. Quick mold changes and low maintenance needs contribute to seamless production, improving overall productivity and reducing downtime.

FAQ

Q: What materials can the 5L Extrusion Blow Moulding Machine handle?

A: This machine is compatible with HDPE, LDPE, and PP materials, providing flexibility in production for various industries.

Q: How fast is the production speed?

A: The machine is capable of producing up to 70 kg/hr, ensuring high-speed production for large volumes of 5L bottles.

Q: How easy is it to maintain the machine?

A: The machine features a user-friendly control system and automatic lubrication, ensuring low maintenance and minimal downtime for continuous production.

Product Parameters

| Parameter | Value |

| Extruding Screw Diameter | Ø70mm |

| Screw L/D Ratio | 25:1 |

| Plasticizing Capacity | 70 KG/hr |

| Extruding Method | Inverter motor, Gearbox |

| Driving Power | 22 kW |

| Screw Revolution | 10-100 rpm |

| Heating Power | 3Φ7.5 kW |

| Blower Power | 120W |

| Clamping Force | 60 kN |

| Mold Thickness Range | 138-180 mm |

| Platen Dimension | 370 x 390 mm (W x H) |

| Idle Cycle Time | 700x2 pcs/hr |

| Parison Thickness Control | MOOG 100-point |

| Clamping Unit Structure | Large arm with joint operation |

| Hydraulic Oil Motor Power | 7.5 kW |

| Control System | Mitsubishi PLC |

| Human Interface Screen | HITECH (Taiwan) |

| Overall Dimensions | 3430 x 2320 x 2650 mm |

| Weight | 7.0 T |

| uint | item | specification | discription | note |

Extruding | Screw diameter | φ70mm | Mixing model |

|

| Screw L/D | 25:1 |

|

|

| Material of screw and barrel |

| 38CrMoALA |

|

| Plasticizing capacity | 70KG/Hr | Based on HDPE5502, changed with different material density |

|

| Extruding method |

| Inverter motor, hardness tooth surface gear box |

|

| Driving power | 22KW |

|

|

| Screw revolution | 10—100rpm |

|

|

| Heating zones | 3 | Temperature module, Mitsubishi |

|

| Heating power | 3φ7.5KW |

|

|

| blowers | 3 | Power 120W |

|

| cooling | yes | Cooling water for feeding zone and gear box |

|

| Clamping unit | Structure

|

| Large arm and joint operation type, with large and average clamping force |

|

| Idle cycle time | 700×2 pc/h |

|

|

| Platen dimension | 370×390 mm | W×H |

|

| Platen distance | 148~508mm |

|

|

| Clamping force | 60KN |

|

|

| Mold thickness scope | 138~180 mm |

|

|

| stroke | 320mm |

|

|

| Die head | structure | continuous | Central feeding |

|

| Center distance | 60mm | Quadruple head |

|

| Material |

| 38CrMoALA inner mirror |

|

| Die mouth | Φ10~Φ80 mm |

|

|

| Heating method |

| Stainless steel band |

|

| Heating zones | 4 |

|

|

| Die head blowing | Yes |

|

|

| Parison thickness controlling | available | MOOG 100-point |

|

| Parison adjustment method | Outer mandral |

|

|

| Adjustment | ±2 mm |

|

|

Up blowing

unit |

|

| Equip with a set of double head & double blowing |

|

| Controlling system | Temperature | Module | Mitsubishi |

|

| Programmer | Mitsubishi |

|

|

| Human interface screen | HITECH | Taiwan |

|

| hydraulic | Oil motor power | 7.5KW |

|

|

| Brand | HYTEK | Taiwan |

|

| Controlling | proportional |

|

|

| Max. working pressure | 140 kg/cm2 |

|

|

| Pneumatics | maker | AIRTEC | Taiwan |

|

| Pressure controlling |

| Separate two adjusters for high and low pressure |

|

| Max. pressure | 8kg/cm,1.0m3/min |

|

|

Other information

| Lubricative method |

| Auto lubricate oil pump |

|

| Overall dimension | L*W*H | 3430*2320*2650mm |

|

| weight | TON | 7.0T |

|

Hydraulic Parts

| Name | Supplier |

| Oil Pump | YUKEN, Japan

OR HYTEK, Taiwan |

| Hydraulic Valve | YUKEN, Japan |

| Proportional Valve | YUKEN, Japan |

| Solenoid Valve | YUKEN, Japan |

Electrical Parts

| Name | Supplier |

| Microcomputer Control System | MITSUBISHI PLC, Japan |

| Touch Screen | INOVANCE |

| Parison Controller & servo valve | MOOG, Japan |

| Contactor | SCHNEIDER, France |

| Air Switch | SCHNEIDER, France |

| Motor | SIMENS BEIDE, Germany |

| Power Resource | MEAN WELL, Taiwan |

| Inverter | MITSUBISHI, Japan |

| Relay | OMRON, Japan |

Pneumatic Parts

| Name | Supplier |

| Air valve | FESTO, Germany |

| Cylinder | FESTO, Germany |